zitsulo mauna zimbale

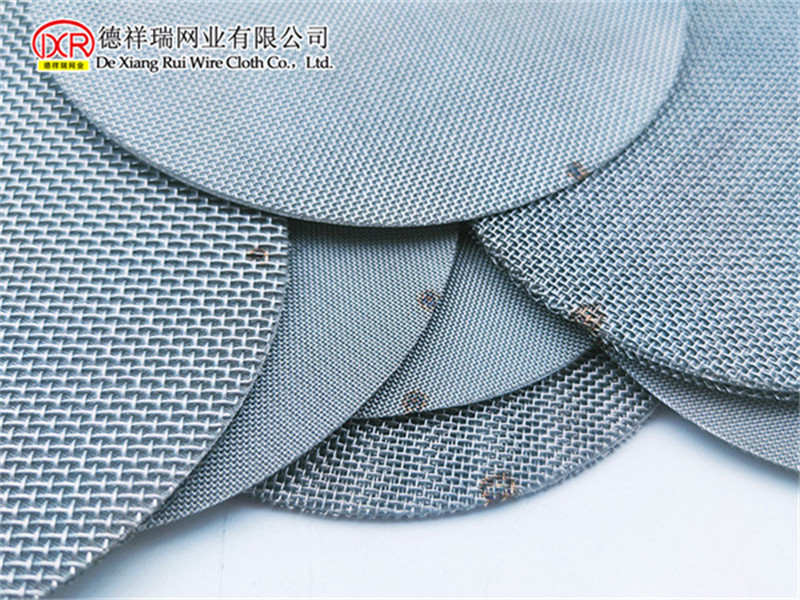

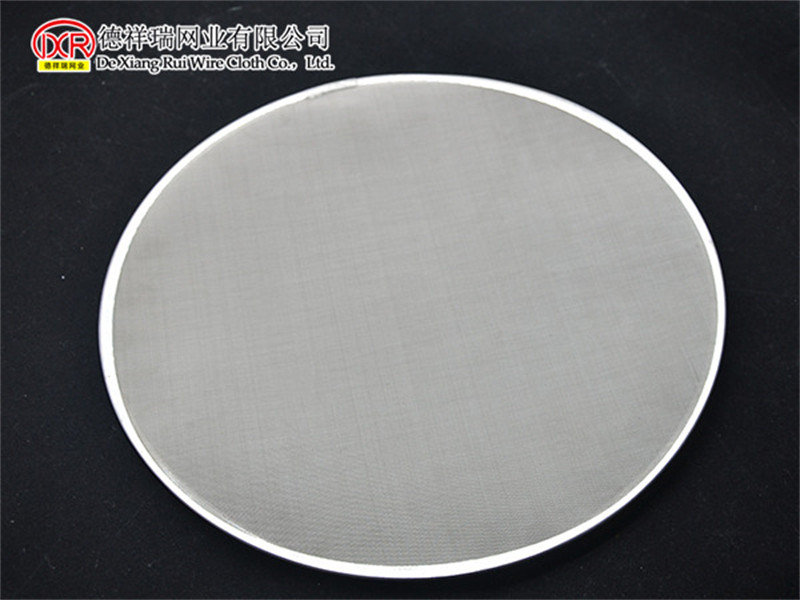

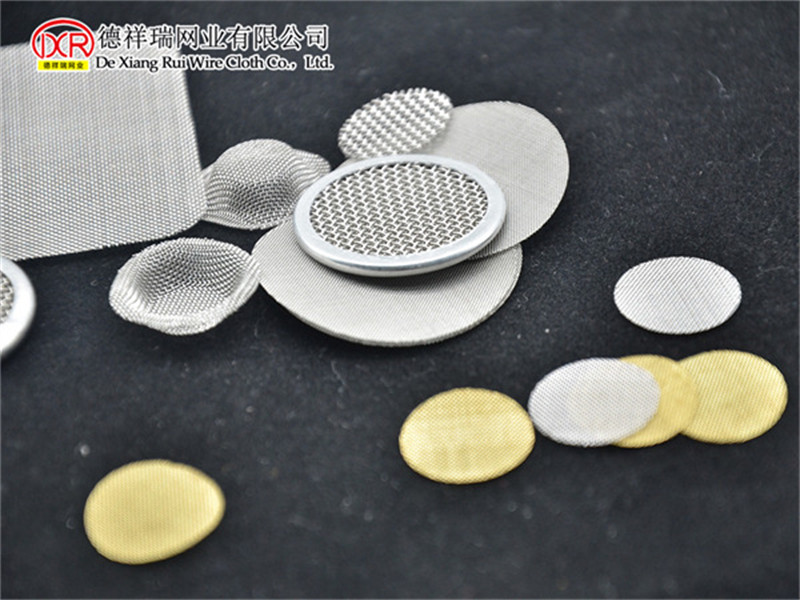

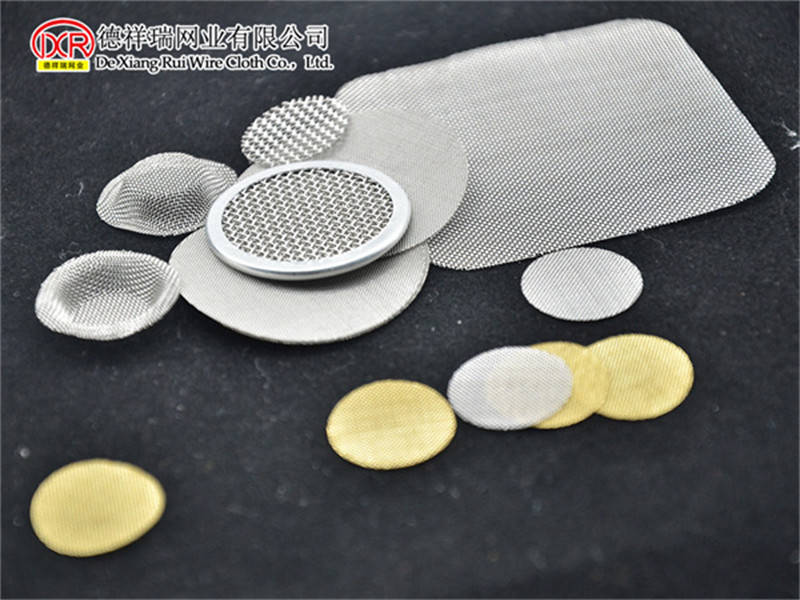

Metal mesh discs ndi gawo lazosefera zamafakitale zopangidwa ndi chitsulo chosapanga dzimbiri, zojambulazo za aluminiyamu ndi zida zina zachitsulo monga maziko ake kudzera pakuluka, kupondaponda, kupukuta kapena kupukuta kooneka ngati mafunde. Ili ndi mawonekedwe a kutentha kwapamwamba, kukana kwa dzimbiri, mphamvu zambiri komanso kuyeretsa kosavuta. Amagwiritsidwa ntchito kwambiri mu petrochemical, kuyeretsa mpweya, kukonza chakudya, kupanga makina ndi zina.

1. Zinthu ndi magulu

Kugawa ndi zinthu

Ma mesh achitsulo chosapanga dzimbiri: Wopangidwa ndi waya wachitsulo chosapanga dzimbiri ngati zinthu zosapanga dzimbiri, amapangidwa kudzera pakuluka, kupondaponda kapena kusisita. Ili ndi kukana kwambiri kwa dzimbiri komanso mphamvu zamakina ndipo ndi yabwino kwa asidi amphamvu, alkali wamphamvu kapena malo otentha kwambiri.

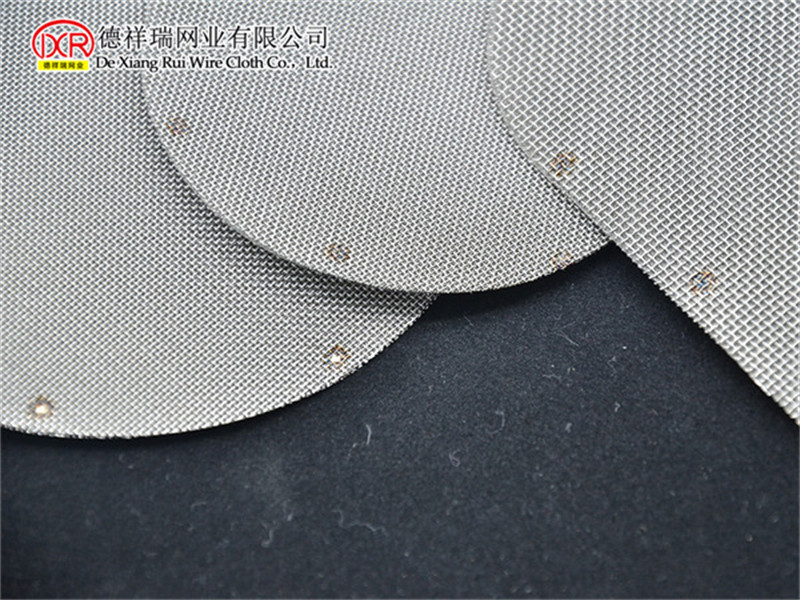

Aluminium zojambulazo zosefera mauna: Zimagwiritsa ntchito mauna owonjezera a aluminiyamu owonjezera kuti apange mawonekedwe a wavy kudzera pakugudubuzika. Kuchita bwino kwa kusefera kumatheka ndi cross-lamination. Ili ndi mawonekedwe a mpweya waukulu wa mpweya, kukana koyambirira kocheperako komanso kukana kwamphamvu kwamoto.

Ma mesh ena achitsulo: kuphatikiza ma mesh amkuwa, ma mesh, ma mesh amabwalo akulu, ma mesh achitsulo, ndi zina zambiri, ndipo zinthuzo zitha kusankhidwa malinga ndi zosowa zosiyanasiyana.

Kugawa ndi ndondomeko

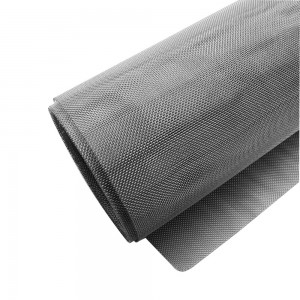

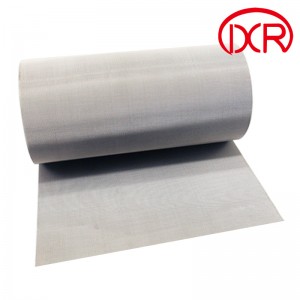

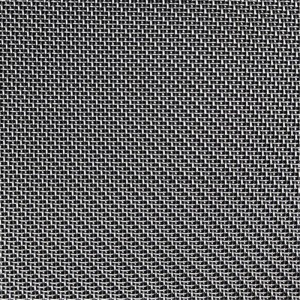

Mtundu wolukidwa: Waya wachitsulowo amalukidwa kukhala ma mesh kudzera pa loom, kenako amadulidwa, kusindikiza ndi njira zina. Kukula kwa pore kumakhala kofanana komanso kutulutsa mpweya wabwino.

Mtundu wa stamping: Gwiritsani ntchito nkhonya kuti mukhome mabowo okhazikika pa mbale yachitsulo kuti mupange sefa yooneka ngati mbale yokhala ndi mpweya wokwanira komanso wotsika mtengo.

Sintering mtundu: Mipikisano wosanjikiza zitsulo zitsulo mauna sintered pa kutentha kwambiri kupanga porous dongosolo ndi mphamvu mkulu ndi kukhazikika bwino. Ndizoyenera kutentha kwambiri, kuthamanga kwambiri kapena malo owononga kwambiri.

Mtundu wopindika wooneka ngati mafunde: Ma mesh a aluminiyamu kapena chitsulo chosapanga dzimbiri amagwiritsidwa ntchito ngati maziko, ndipo amakulungidwa kukhala wavy. Zigawo zingapo zimadutsana kuti ziwongolere bwino kusefera posintha komwe madzi amayendera.

2. Makhalidwe ndi ubwino

Makhalidwe amapangidwe

Mapangidwe amitundu yambiri: Chojambula cha aluminiyamu kapena chitsulo chosapanga dzimbiri chimakulungidwa mu mawonekedwe a wavy, ndipo zigawo zingapo zimadutsana, kotero kuti madzi amadzimadzi amasintha njira nthawi zambiri akadutsa, kumapangitsa kuti tinthu tigwire bwino.

Kachulukidwe kachulukidwe ka gradient: Ma mesh amakonzedwa kuchokera ku coarse kupita ku chabwino, mphamvu yogwira fumbi imachulukitsidwa ndi 40%, ndipo kukana koyamba kumachepetsedwa ndi 15% -20%.

Kutentha kwakukulu ndi kukana kwa dzimbiri: Zida zachitsulo zimatsimikizira kukana kwa dzimbiri ndi mphamvu zamakina, ndipo moyo wautumiki ukhoza kufika nthawi 2-3 kuposa zosefera wamba.

Kukana kwamphamvu kwamoto: Yadutsa chiphaso chokhazikika cha GB/T 5169 ndipo ili ndi zida zabwino kwambiri zozimitsa moto.

Ubwino wogwira ntchito

Kusefedwa kwapamwamba kwambiri: Mapangidwe amitundu yambiri amathandizira kwambiri kugwidwa kwa tinthu tating'onoting'ono ndipo ndi koyenera kwa zochitika zosefera.

Kukhazikika kwamphamvu: Chitsulocho sichimva kuvala komanso kukalamba, ndipo chimatha kugwira ntchito mokhazikika kwa nthawi yayitali.

Zosavuta kuyeretsa ndi kukonza: Mapangidwe a mbale ndi opepuka, amathandizira m'malo mwaodziyimira pawokha, ndipo amakhala ndi ndalama zotsika mtengo.

Makonda osinthika: Imathandizira makonda osayembekezeka, ndipo chimango chakunja chimatha kusankhidwa ngati chimango chagalasi, chimango cha aluminiyamu aloyi, ndi zina kuti zikwaniritse zosowa zosiyanasiyana.

3. Zochitika zogwiritsira ntchito

Kusefera kwa mafakitale

Petrochemical: Ntchito yolekanitsa, kuyeretsa ndi kuchuluka kwa gasi kapena madzi, monga distillation, mayamwidwe, evaporation ndi njira zina.

Kukonza chakudya: Sefa zonyansa mumadzimadzi kapena gasi kuti mutsimikizire chiyero chazinthu.

Kupanga makina: Monga gawo losefera pamakina a hydraulic ndi makina opaka mafuta, amateteza zida ku kuwonongeka kwa tinthu.

Kuyeretsa mpweya

Makina a HVAC: Amagwiritsidwa ntchito ngati kusefera kwapakati kwa mpweya wapakati ndi zida zopumira mpweya kuti agwire tinthu tating'onoting'ono tokulirapo kuposa ma microns 10.

Chipinda choyera: Monga chipangizo chosefera chisanadze, chimakulitsa moyo wautumiki wa zosefera zapamwamba kwambiri.

Malo otentha kwambiri: Monga migodi yazitsulo, malo opangira penti, etc., kusefa fumbi ndi mafuta mu mpweya wotentha kwambiri.

Zochitika zapadera

Kupanga magalimoto: amagwiritsidwa ntchito kusefera mafuta m'zipinda zopopera phula ndi zipinda zopoperapo utoto kuti ateteze kuipitsidwa kwa malo ochitira msonkhano.

Ukadaulo wamagetsi: zosefera zoyera zochitira msonkhano kuti zitsimikizire malo opanda fumbi.

Zamankhwala ndi Zaumoyo: Zomwe zimagwiritsidwa ntchito pakusefera mpweya muzachilengedwe, mafakitale azakudya ndi zakumwa, mogwirizana ndi miyezo yaukhondo.

5. Njira yopanga

Njira yoluka: Waya wachitsulo chosapanga dzimbiri amalukidwa kukhala mauna kudzera pa ulusi woluka, kenako amatenthedwa kuti awonjezere mphamvu ndi kulimba.

Kukhomerera: gwiritsani ntchito nkhonya kuti mukhomere mabowo okhazikika pa mbale yachitsulo kuti mupange mawonekedwe ofananira ndi mbale.

Sintering ndondomeko: Mipikisano wosanjikiza zitsulo waya mauna sintered pa kutentha kupanga porous dongosolo kulimbitsa mphamvu ndi dzimbiri kukana.

Njira yolumikizirana yooneka ngati mafunde: zojambulazo za aluminiyamu kapena mauna achitsulo chosapanga dzimbiri amakulungidwa kuti apange mawonekedwe a mafunde, ndipo zigawo zingapo zimayikidwa pamtanda ndikukhazikika pa chimango.

Kuchiza pamwamba: electroplating, kupenta kapena kupopera zitsulo mauna kuti kukana dzimbiri ndi kukongola.