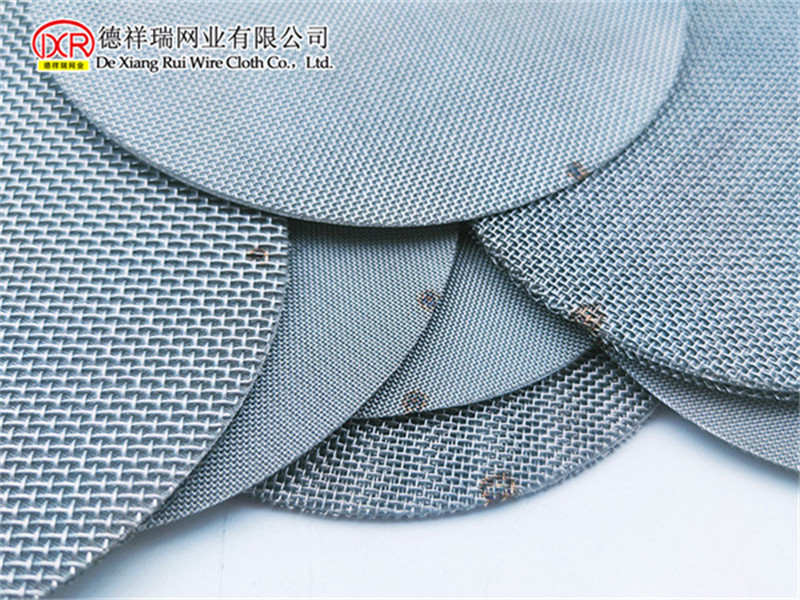

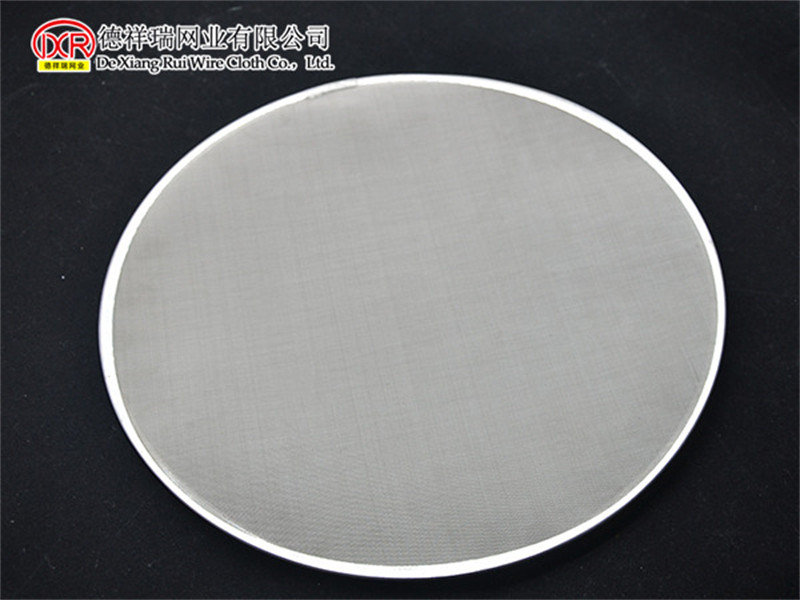

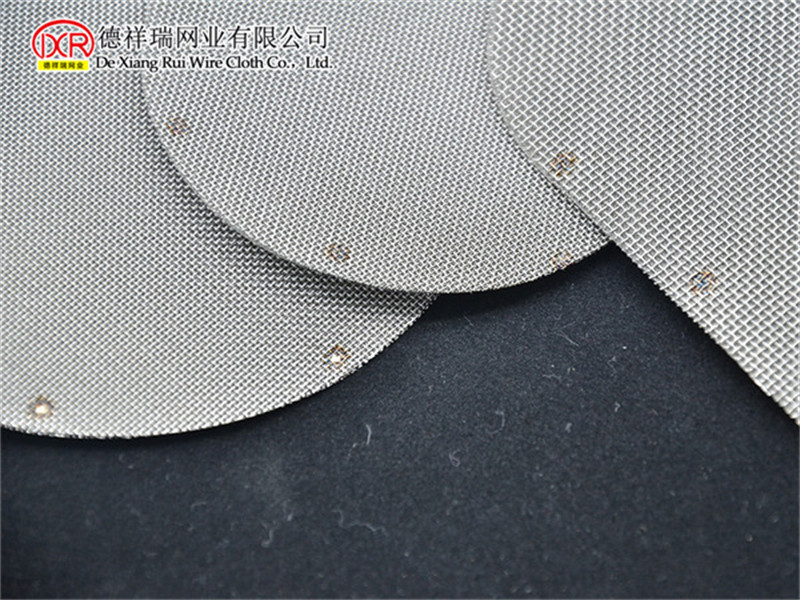

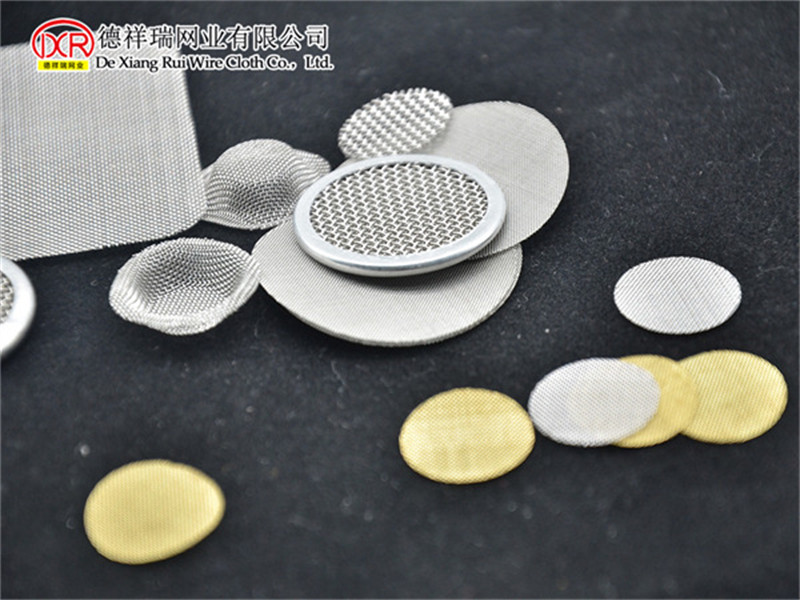

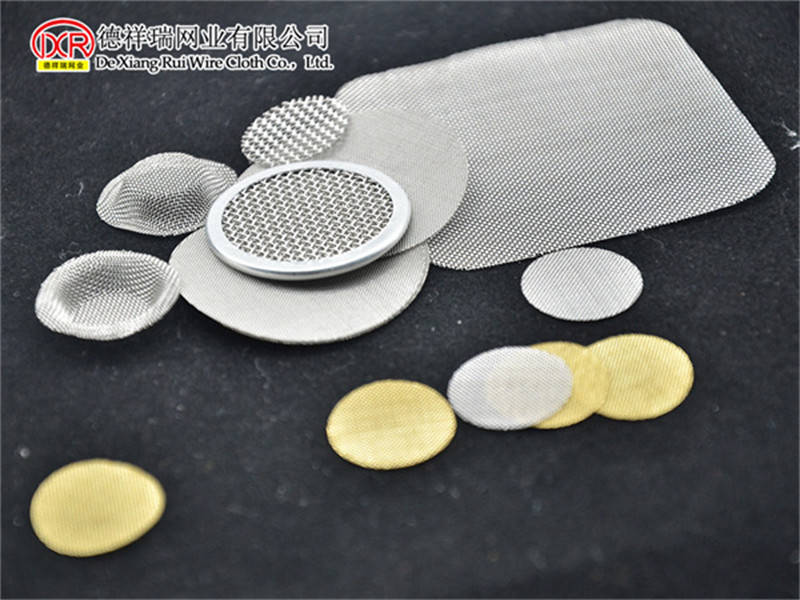

metal mesh discs

Ama-Metal mesh discs ayingxenye yesihlungi semboni eyenziwe ngensimbi engagqwali, ucwecwe lwe-aluminium nezinye izinto zensimbi njengesisekelo sempahla ngokusebenzisa ukwelukwa, ukugxiviza, ukucwiliswa kwe-sintering noma okumise okwegagasi. Inezici zokumelana nokushisa okuphezulu, ukumelana nokugqwala, amandla aphezulu nokuhlanza okulula. Isetshenziswa kabanzi ku-petrochemical, ukuhlanzwa komoya, ukucubungula ukudla, ukukhiqizwa kwemishini neminye imikhakha.

1. Impahla kanye nezigaba

Ukuhlukaniswa ngokwezinto ezibonakalayo

I-Stainless steel filter mesh: Yenziwe ngensimbi engenasici njengensimbi engagqwali, yenziwa ngenqubo yokweluka, yokunyathela noma yokucwilisa. Inokumelana nokugqwala okuhle kakhulu namandla emishini futhi ifanele i-asidi eqinile, i-alkali eqinile noma indawo yokushisa ephezulu.

Imeshi yesihlungi se-aluminium foil: Isebenzisa i-aluminium foil enemeshi enwetshiwe enezingqimba eziningi ukuze yakhe isakhiwo esinamagagasi ngokugingqika. Ukusebenza kahle kokuhlunga kuthuthukiswa nge-cross-lamination. Inezici zomthamo omkhulu wokungenisa umoya, ukumelana okuphansi kokuqala kanye nokumelana nomlilo okuqinile.

Enye insimbi yensimbi: kufaka phakathi i-copper mesh, i-mat mesh, i-galvanized square mesh, i-mesh plate mesh, njll., futhi impahla ingakhethwa ngokuya ngezidingo ezahlukene.

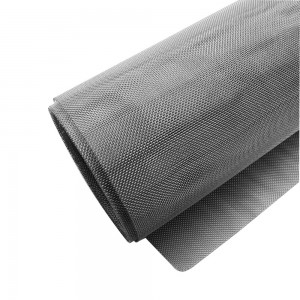

Ukuhlukaniswa ngenqubo

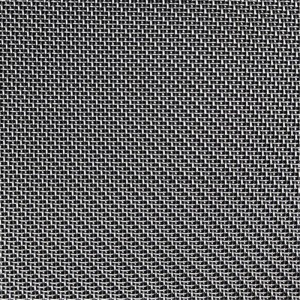

Uhlobo olulukiweyo: Ucingo lwensimbi lulukwa lube yisakhiwo semeshi ngohlaka, bese luyasikwa, lugxivizwe nezinye izinqubo. Ubukhulu bembotshana bufana futhi nokungena komoya kuhle.

Uhlobo lokunyathela: Sebenzisa i-punch ukuze ubhoboze izimbobo ezivamile epuleti lensimbi ukuze wakhe ukwakheka kwesihlungi esimise okwepuleti esinomoya onamandla kanye nezindleko eziphansi.

Uhlobo lwe-Sintering: I-Multi-layer metal wire mesh ifakwe emanzini okushisa aphezulu ukuze yakhe isakhiwo esinezimbotshana esinamandla aphezulu kanye nokuqina okuhle. Ifanele izinga lokushisa eliphezulu, ingcindezi ephezulu noma indawo egqwala kakhulu.

Uhlobo olugqagqene olumise okumagagasi: I-aluminium foil mesh noma insimbi engagqwali isetshenziswa njengento eyisisekelo, futhi igoqwa ibe yisimo esigagasi. Izendlalelo eziningi ziyagqagqana ukuze kuthuthukiswe ukusebenza kahle kokuhlunga ngokushintsha isiqondiso soketshezi.

2. Izimpawu kanye nezinzuzo

Izici zesakhiwo

Idizayini ye-wavy enezingqimba eziningi: I-aluminium foil noma insimbi engagqwali enemeshi igoqeka ibe yisimo esinamagagasi, futhi izendlalelo eziningi zigqigqene, ukuze uketshezi lushintshe indlela izikhathi eziningi lapho ludlula, kuthuthukisa kakhulu ukusebenza kahle kwezinhlayiyana zokuthwebula.

Ukuhlelwa kwe-Density gradient: I-mesh ihlelwa kusukela kumaholoholo kuya kokucolekile, umthamo wokubamba uthuli ukhuphuka cishe ngo-40%, futhi ukumelana kokuqala kuncipha ngo-15% -20%.

Ukushisa okuphezulu nokumelana nokugqwala: Izinto zensimbi ziqinisekisa ukumelana nokugqwala namandla emishini, futhi impilo yesevisi ingafinyelela izikhathi ezingu-2-3 kunezihlungi ezivamile.

Ukumelana nomlilo okuqinile: Idlulise isitifiketi esijwayelekile se-GB/T 5169 futhi inezindawo ezinhle kakhulu zokuvimbela umlilo.

Izinzuzo zokusebenza

I-High-efficiency filtration: Isakhiwo sezendlalelo eziningi sithuthukisa kakhulu ukusebenza kahle kwezinhlayiyana futhi sifanele izimo zokuhlunga ngokunemba.

Ukuqina okuqinile: Into yensimbi ayigugi futhi ayigugi, futhi ingasebenza ngokuzinza isikhathi eside.

Kulula ukuhlanza nokunakekela: Isakhiwo sepuleti asisindi, sisekela ukushintshwa okuzimele komsebenzisi, futhi sinezindleko eziphansi zokusebenza.

Ukwenza ngokwezifiso okuguquguqukayo: Isekela usayizi ongajwayelekile ongajwayelekile, futhi ifreyimu yangaphandle ingakhethwa njengohlaka oluphehliwe, uhlaka lwe-aluminium alloy, njll. ukuze kuhlangatshezwane nezidingo ezahlukahlukene.

3. Izimo zohlelo lokusebenza

Ukuhlunga kwezimboni

I-Petrochemical: Isetshenziselwa ukuhlukanisa, ukuhlanzwa kanye nokugxila kwegesi noma uketshezi, okufana ne-distillation, ukumuncwa, ukuhwamuka nezinye izinqubo.

Ukucubungula ukudla: Hlunga ukungcola oketshezini noma igesi ukuze uqinisekise ubumsulwa bomkhiqizo.

Ukwenziwa kwemishini: Njengengxenye yokuhlunga yezinhlelo ezisebenza ngamanzi kanye nezinhlelo zokuthambisa, kuvikela okokusebenza ekulimaleni kwezinhlayiyana.

Ukuhlanzwa komoya

Isistimu ye-HVAC: Isetshenziselwa ukuhlunga okuyinhloko kwesimo somoya esimaphakathi nemishini yokukhipha umoya ukuze ithwebule izinhlayiya zomoya ezinkulu kuno-10 microns.

Igumbi elihlanzekile: Njengedivayisi yokuhlunga ngaphambilini, inweba impilo yesevisi yezihlungi ezisebenza kahle kakhulu.

Imvelo enezinga eliphezulu lokushisa: Njengezimayini zensimbi, izindawo zokusebenzela zokudweba, njll., ukuhlunga uthuli namafutha kumagesi asezingeni eliphezulu.

Izimo ezikhethekile

Ukukhiqizwa kwezimoto: kusetshenziselwa ukuhluza inkungu kawoyela emakamelweni okufafaza nge-wax kanye namagumbi okufafaza ngopende ukuvikela ukungcoliswa kwendawo yokusebenzela.

Ubuchwepheshe be-elekthronikhi: hlunga umoya ohlanzekile weshabhu ukuze uqinisekise indawo yokukhiqiza engenazo izintuli.

Ezokwelapha nempilo: isetshenziselwa ukuhlunga umoya omncane emikhiqizweni yebhayoloji, ezimbonini zokudla neziphuzo, ngokuhambisana nezindinganiso zokuhlanzeka.

5. Inqubo yokukhiqiza

Inqubo yokweluka: Intambo yensimbi engagqwali ilukwa ibe isakhiwo semeshi ngendwangu yokuluka, bese iphathwa ukushisa ukuze kuthuthukiswe amandla nobulukhuni.

Inqubo yokubhoboza: sebenzisa isibhakela ukuze ubhoboze izimbobo ezivamile epuleti lensimbi ukuze wakhe ukwakheka kwesihlungi esifana nepuleti.

Inqubo ye-Sintering: I-multi-layer metal wire mesh is sintered at high temperatures to form a porous structure ukuthuthukisa amandla nokumelana nokugqwala.

Inqubo egqagqene emise okumagagasi: i-aluminium foil noma insimbi engagqwali enemeshi igoqwa ukuze kwakheke umumo wegagasi, futhi izendlalelo eziningi zine-laminated futhi zigxiliswe kuhlaka.

Ukwelashwa okungaphezulu: i-electroplating, ukudweba noma ukufafaza i-mesh yensimbi ukuthuthukisa ukumelana nokugqwala kanye nobuhle.