I-Stainless steel wire mesh yokuhlola impushana yebhethri

Ekuhloleni impushana yebhethri, ukukhethwa kanye nokusetshenziswa kwensimbi engagqwali yensimbi enezikhala kudinga ukuhlanganiswa nezici zempahla, imingcele ebekiwe, inqubo yokuluka kanye nezimo zangempela zokusebenza. Okulandelayo ukuhlaziya okuqondile:

1. Ukukhetha izinto ezibonakalayo

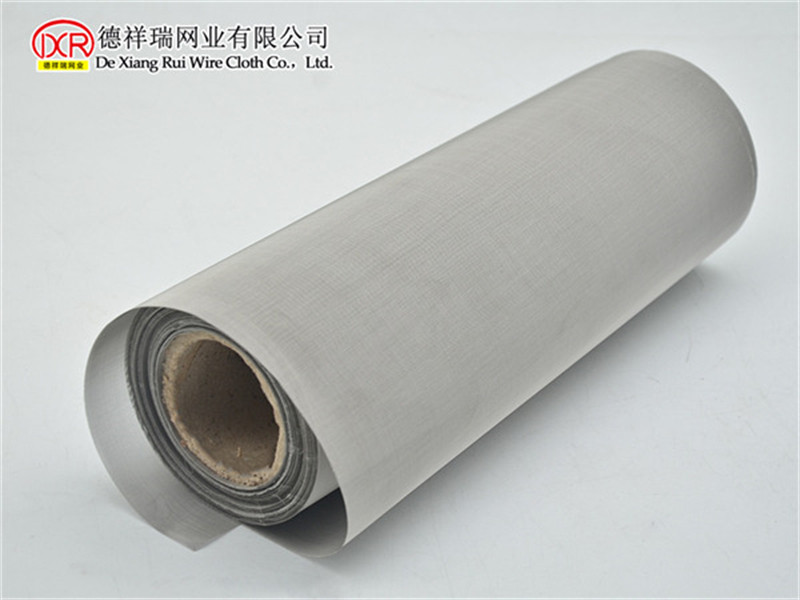

304 insimbi engagqwali

Izici: Ukumelana nokugqwala okuhle, kulungele indawo yamakhemikhali ejwayelekile, izindleko eziphansi.

Isimo sohlelo lokusebenza: Ukuhlolwa kwempushana kwebhethri okuvamile, okukhethwayo uma ingekho into eqinile elimazayo.

316 insimbi engagqwali

Izici: Ukwengeza isici se-molybdenum, ukumelana nokugqwala kuthuthukiswa kakhulu, kulungele umswakama ophezulu noma indawo egqwala yamakhemikhali.

Isimo sohlelo lokusebenza: Izindawo ezisogwini, i-asidi eqinile kanye nemvelo ye-alkaline, noma ukuhlolwa kwezinto ezisebenza kahle zama-electrode ezinezidingo eziphezulu zokumelana nokugqwala.

2. Imininingwane

Inombolo ye-mesh nembobo

I-200 mesh: indawo yokuvula icishe ibe ngu-0.075mm, ilungele ukuhlolwa kwasekuqaleni ukuze kukhishwe ukungcola kwezinhlayiyana ezinkulu.

I-300 mesh: indawo yokuvula icishe ibe ngu-0.045mm, isetshenziselwa ukucwenga usayizi wezinhlayiyana kanye nokusebenza kahle kokuhlolwa kwebhalansi nokunemba.

I-400 mesh: Imbobo icishe ibe ngu-0.038mm, ihlinzeka ngokunemba okuphezulu kokuhlola futhi ihlangabezana nezidingo eziqinile zosayizi wezinhlayiyana.

Ububanzi bentambo

Ububanzi bentambo buthinta amandla nokunemba kokuvuleka kwesikrini. I-fine wire diameter (efana no-0.038mm) ingathuthukisa ukunemba, kodwa ukumelana nokugqokwa kudinga ukulingana; I-diameter yentambo eqinile (efana no-0.05mm) ithuthukisa amandla, kodwa ingase yehlise izinga lokuvula.

3. Inqubo yokweluka

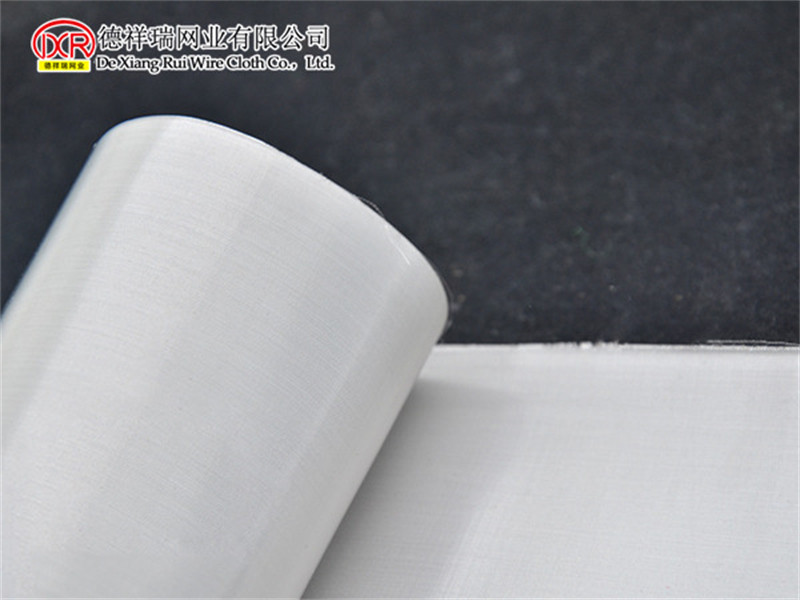

I-Plain weave

Isakhiwo: Izintambo ze-warp ne-weft zixhunywe zibheke phezulu, i-mesh iyunifomu, futhi amandla aphezulu.

Isicelo: Ifanele ukuhlolwa okuqinile noma izidingo zokunemba okuvamile.

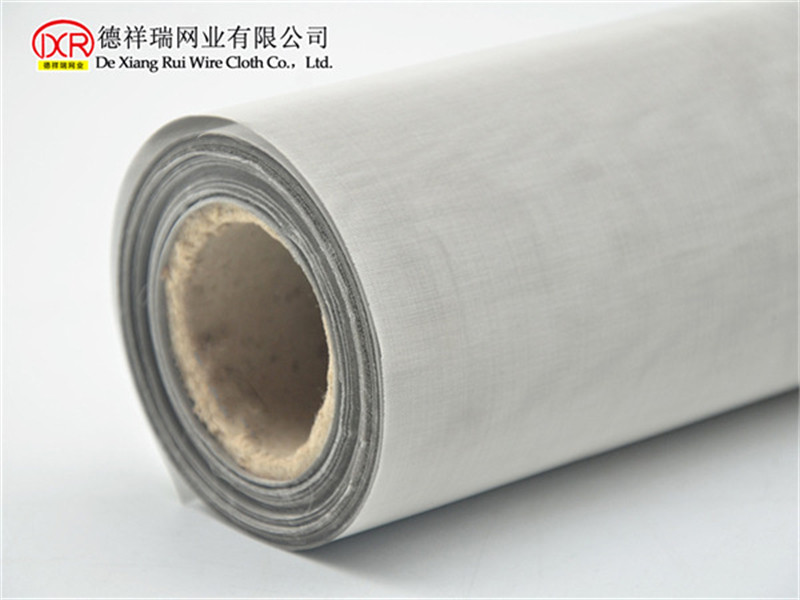

Twill weave

Isakhiwo: Izintambo ze-warp ne-weft zixhumene ngokugobile, i-porosity iphakeme, kanye nokusebenza kahle kokuhlola kuyathuthukiswa.

Isicelo: Ukuhlolwa okunembayo okuphezulu, njengokukhiqizwa kwezinto ezibonakalayo zama-electrode.

4. Izidingo zokusebenza ezibalulekile

Ukumelana nokugqwala

Ngesikhathi sokukhiqizwa kwebhethri, ama-electrolyte nezinto ezisekelwe kwi-asidi zingase zidalulwe, futhi ukuqina kwesikhathi eside kwesikrini kufanele kuqinisekiswe.

Amandla nokumelana nokugqoka

Phakathi nenqubo yokuhlola, isikrini singaphansi kokudlidliza nomthelela wezinto ezibonakalayo, futhi isakhiwo kufanele sizinze ukuze sinwebe impilo.

Kulula ukuhlanza

Ingaphezulu libushelelezi futhi alinawo amakhona afile, okunciphisa izinsalela zempushana futhi kugweme ukungcoliswa okuphambanayo.

5. Izimo zohlelo lokusebenza nokwenza kahle

Uhlelo lokuhlola olunezigaba eziningi

Ukucushwa: Inhlanganisela ye-mesh engu-200 + 400 mesh, ukuhlolwa kokuqala okuqinile bese kuba ukuhlolwa okuhle, ukuthuthukisa ukusebenza kahle nokunemba.

Imishini esekelayo

Isikrini sokudlidliza se-Ultrasonic: ukudlidliza kwe-high-frequency kunciphisa ukuvala, kulungele ukuhlolwa kwezinhlayiyana ezinhle.

Uhlelo lokuphakela ngevacuum: lugwema ukundiza uthuli futhi luthuthukisa ukuphepha.

Ukuphathwa kwesondlo

Ukuhlola okuvamile: qapha ukuguga nokuvinjwa, futhi ufake esikhundleni noma uhlanze ngesikhathi.

Ukuhlanza nokunakekela: sebenzisa izinto zokuhlanza ezikhethekile ukuze ugweme ukugqwala okusele.

Isikhathi sokuthumela: May-22-2025