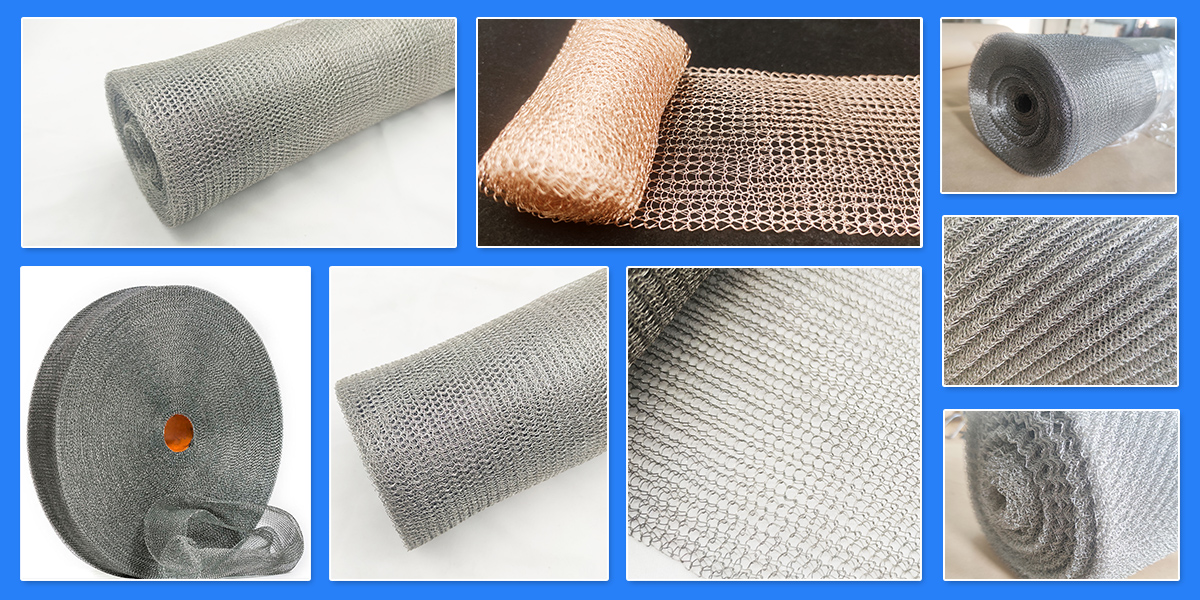

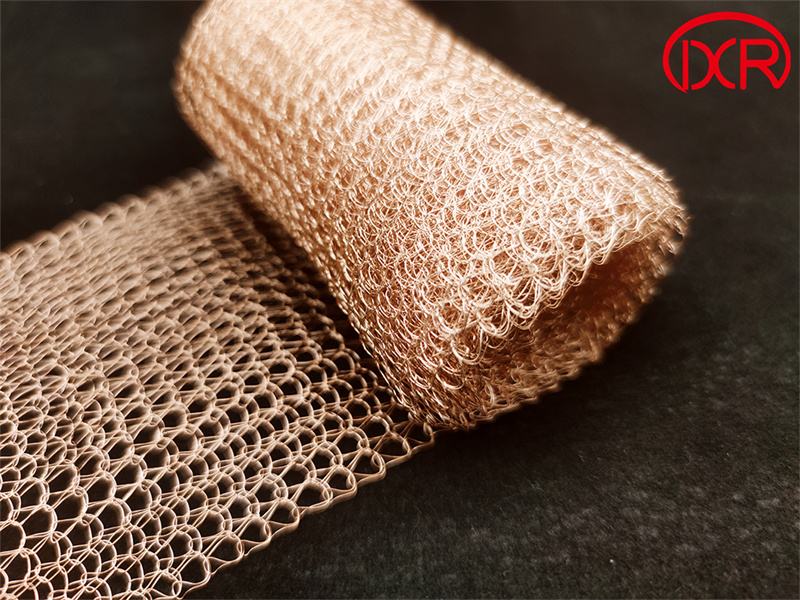

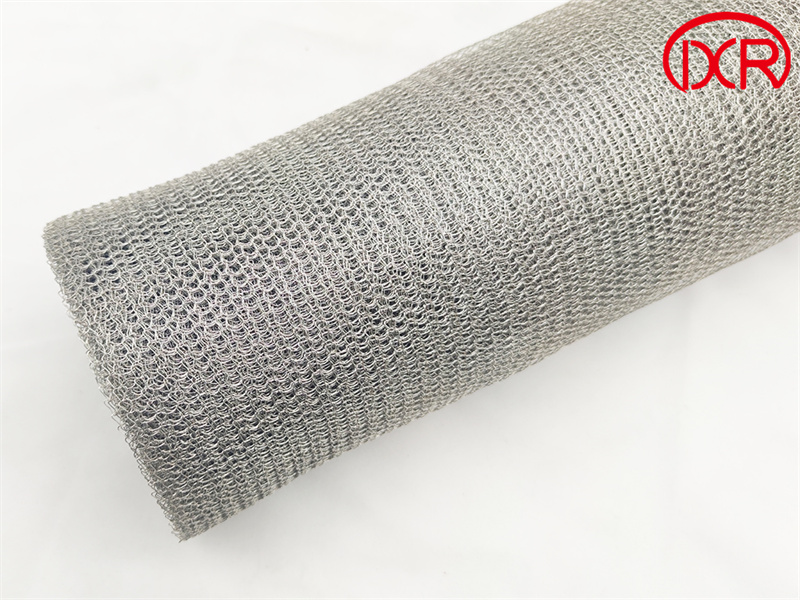

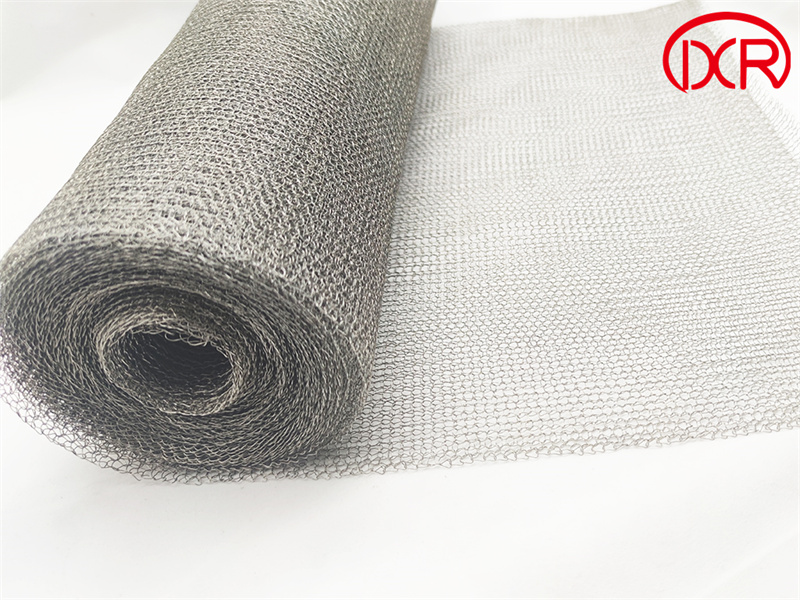

tooj liab knitted hlau mesh

Toojknitted hlau meshyog dav siv nyob rau hauv industrial teb vim nws zoo heev corrosion kuj, thermal conductivity thiab plasticity.

1. Copper knitted hlau mesh sib cais thiab demitting

Hlau mesh demister: siv los cais cov kua tee dej (fog) hauv cov roj hauv cov yees (xws li cov tshuaj tua hluav taws, cov twj nqus dej, cov evaporator), nrog rau qhov pom tseeb ntawm 3 ~ 5μm thiab efficiency ntawm 98% ~ 99.8%.

Daim ntawv thov scenarios:

Petroleum refining (xws li catalytic cracking units, natural gas desulfurization towers).

Kev tsim tshuaj lom neeg (purification ntawm acidic gases xws li sulfuric acid, hydrochloric acid, acetic acid).

Kev lag luam kws tshuaj (cov kuab tshuaj rov qab, kev kho roj pov tseg).

2. Kev tiv thaiv ib puag ncig engineering

Desulfurization thiab demisting: tshem tawm cov tee uas nqa los ntawm SO₂Gas hauv flue gas desulfurization (FGD) systems.

Kev kho dej khib nyiab: siv los ua cov khoom ntim hauv cov tso tsheb hlau luam aeration los ua kom cov pa oxygen hloov pauv tau zoo.

3. Mechanical thiab automotive kev lag luam

Cua compressor / tub yees system: lim roj-dej sib tov hauv compressed cua.

Kev txo suab nrov thiab kev poob siab: raws li cov khoom ntxeem tau suab nrov, txo cov khoom siv suab nrov.

4. Cov khoom siv hluav taws xob thiab kev kho mob

Electromagnetic shielding: siv cov conductivity ntawm tooj liab rau electromagnetic cuam tshuam (EMI) tiv thaiv cov cuab yeej precision.

High-precision filtration: xws li cov khoom siv kho mob cua purification, ultra-ntshiab roj pom hauv kev lag luam semiconductor.

5. Lwm yam kev siv tshwj xeeb

Kub kub ib puag ncig: tooj liab yog resistant rau kub kub (melting point 1083℃), haum rau cov cua kub cua sov thiab boiler tso pa roj kho.

Cov cuab yeej kuaj: customized micro-filters yog siv rau tooj liab knitted hlau mesh tiv tauj hauv tshuaj reactors.