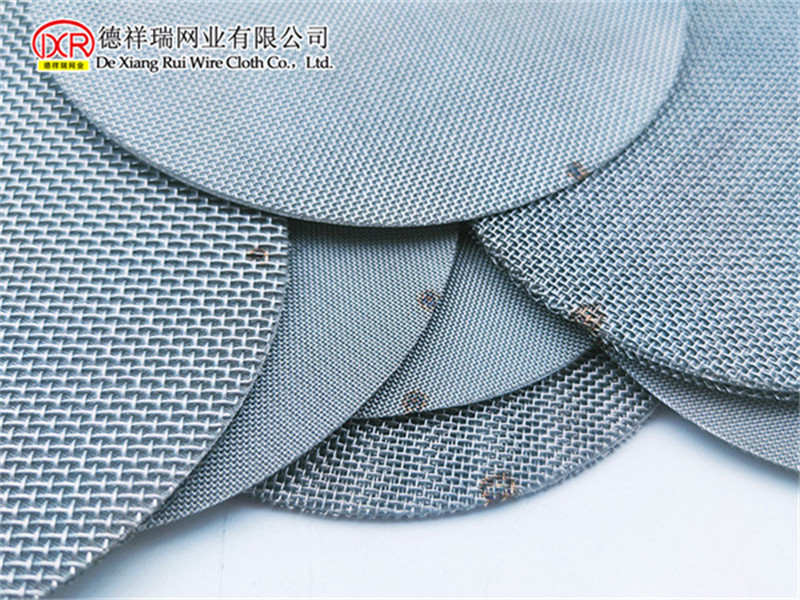

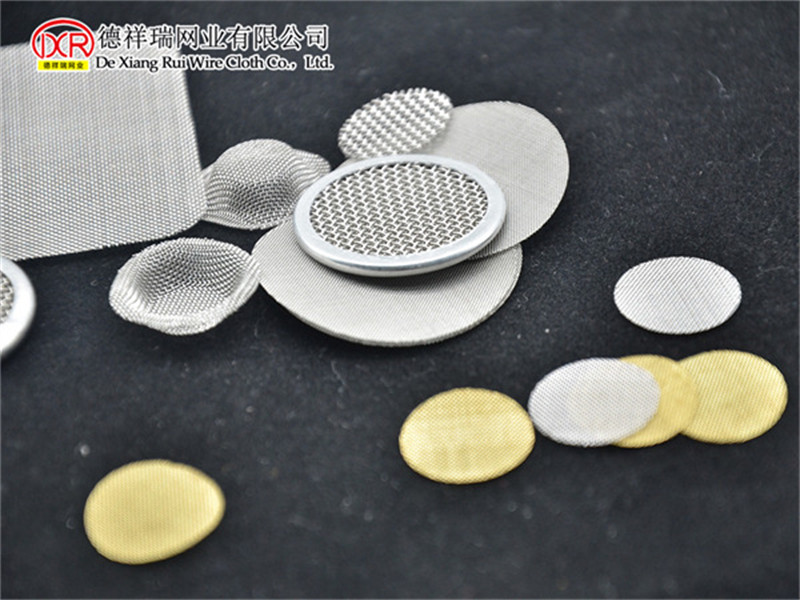

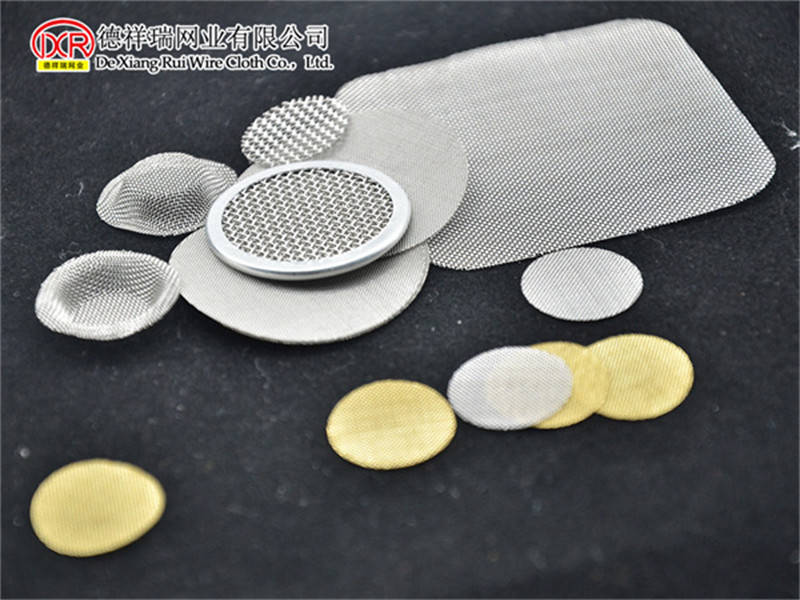

hlau mesh discs

Hlau mesh discs yog cov khoom siv lim dej ua los ntawm cov hlau tsis muaj steel, aluminium ntawv ci thiab lwm cov ntaub ntawv hlau ua cov khoom siv los ntawm kev sib tsoo, stamping, sintering lossis yoj-puab lamination. Nws muaj cov yam ntxwv ntawm qhov kub thiab txias tsis kam, corrosion kuj, siab zog thiab yooj yim tu. Nws yog dav siv nyob rau hauv petrochemical, huab cua purification, zaub mov ua, machinery manufacturing thiab lwm yam teb.

1. Khoom siv thiab kev faib tawm

Kev faib tawm los ntawm cov khoom siv

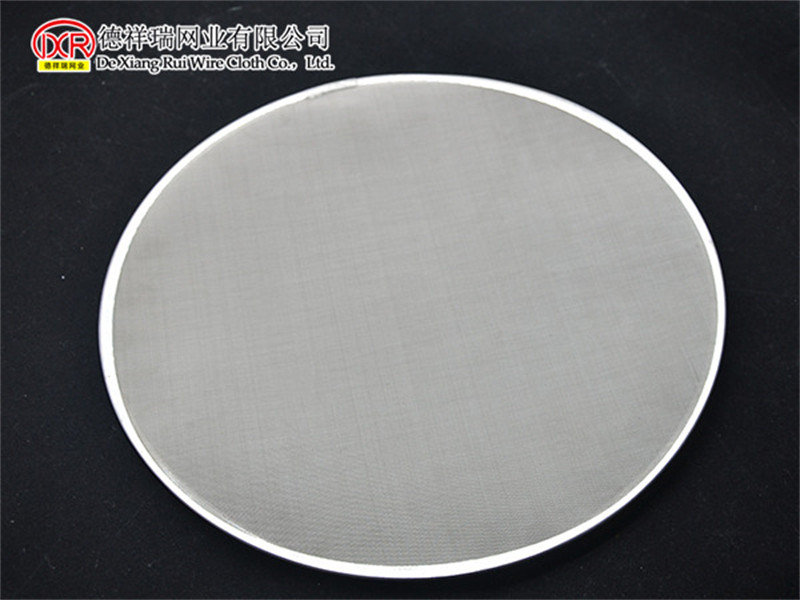

Stainless hlau lim mesh: Ua los ntawm stainless hlau hlau mesh li raw khoom, nws yog tsim los ntawm weaving, stamping los yog sintering txheej txheem. Nws muaj kev tiv thaiv corrosion zoo heev thiab txhua yam muaj zog thiab haum rau muaj zog acid, muaj zog alkali lossis kub ib puag ncig.

Aluminium foil lim mesh: Nws siv ntau txheej nthuav dav aluminium foil mesh los tsim cov qauv wavy los ntawm dov. Qhov pom kev ua haujlwm tau zoo dua los ntawm kev sib tsoo lamination. Nws muaj cov yam ntxwv ntawm qhov cua qhov ntim loj, tsis tshua muaj qhov pib ua haujlwm thiab muaj zog tiv taus hluav taws.

Lwm cov hlau mesh: suav nrog tooj liab mesh, lev mesh, galvanized square mesh, hlau phaj mesh, thiab lwm yam, thiab cov khoom tuaj yeem xaiv raws li qhov xav tau sib txawv.

Kev faib tawm los ntawm txheej txheem

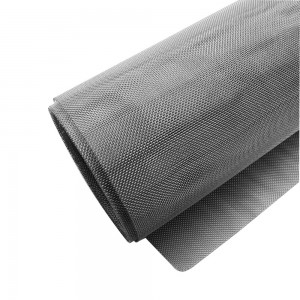

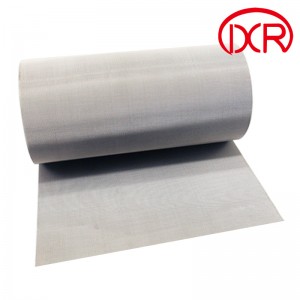

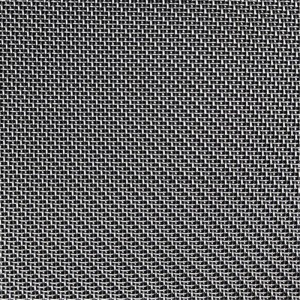

Woven hom: Cov hlau hlau yog woven rau hauv ib lub mesh qauv los ntawm ib tug loom, thiab ces txiav, stamped thiab lwm yam txheej txheem yog ua. Lub pore loj yog uniform thiab huab cua permeability zoo.

Stamping hom: Siv cov xuas nrig ntaus cov qhov tsis tu ncua ntawm cov phaj hlau los ua lub phaj zoo li cov qauv lim uas muaj qhov cua zoo thiab tus nqi qis.

Sintering hom: Ntau txheej hlau hlau mesh yog sintered ntawm qhov kub thiab txias los tsim cov qauv ntxeem tau nrog lub zog siab thiab zoo rigidity. Nws yog qhov tsim nyog rau kev kub siab, kev kub siab lossis ib puag ncig corrosive heev.

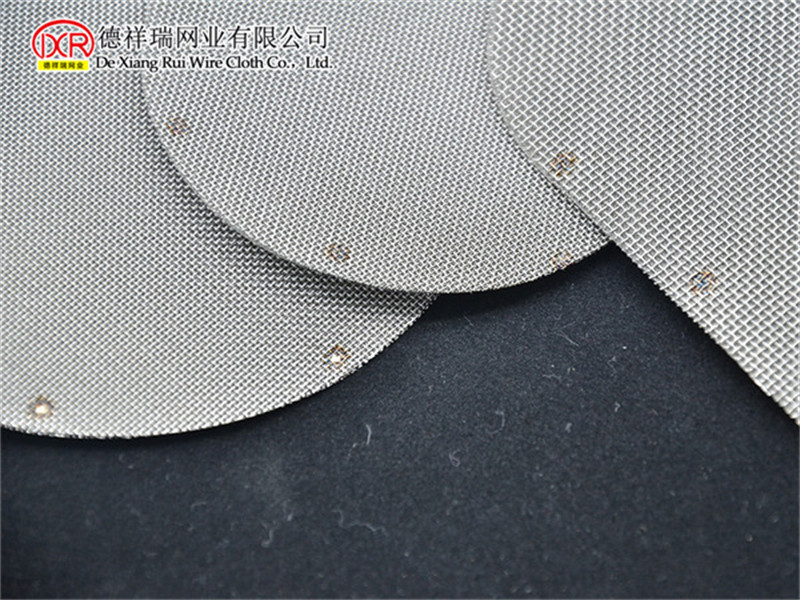

Wave-shaped overlapping type: Aluminium ntawv ci mesh lossis stainless hlau mesh yog siv los ua cov khoom siv hauv paus, thiab nws yog dov rau hauv cov duab wavy. Ntau cov khaubncaws sab nraud povtseg yog cross-overlapped los txhim kho qhov pom kev zoo los ntawm kev hloov cov kev taw qhia ntawm cov kua.

2. Cov yam ntxwv thiab qhov zoo

Cov yam ntxwv ntawm tus qauv

Multi-layer wavy tsim: Aluminium ntawv ci los yog stainless hlau mesh yog dov mus rau hauv ib tug wavy zoo, thiab ntau cov khaubncaws sab nraud povtseg yog cross-overlapped, thiaj li hais tias cov dej hloov cov kev taw qhia ntau zaus thaum dhau mus, ho txhim kho particle capture efficiency.

Qhov tsis zoo ntawm cov kev txhim kho: Lub ntxaij yog npaj los ntawm cov ntxhib kom zoo, cov hmoov av tuav tau nce txog 40%, thiab thawj zaug tsis kam los ntawm 15% -20%.

Kub kub thiab corrosion kuj: cov khoom siv hlau ua kom muaj kev tiv thaiv corrosion thiab txhua yam muaj zog, thiab kev pabcuam lub neej tuaj yeem ncav cuag 2-3 npaug ntawm cov pa lim.

Kev tiv thaiv hluav taws muaj zog: Nws tau dhau los ntawm GB / T 5169 tus qauv ntawv pov thawj thiab muaj cov khoom siv hluav taws xob zoo heev.

Functional zoo

High-efficiency filtration: Cov txheej txheem ntau txheej ua tau zoo txhim kho cov particle capture efficiency thiab yog haum rau precision filtration scenarios.

Lub zog ruaj khov: Cov khoom siv hlau yog hnav-tiv taus thiab aging-resistant, thiab tuaj yeem ua haujlwm ruaj khov rau lub sijhawm ntev.

Yooj yim los ntxuav thiab tswj: Cov qauv phaj yog lub teeb yuag, txhawb cov neeg siv kev ywj pheej hloov pauv, thiab muaj cov nqi khiav lag luam tsawg.

Saj zawg zog customization: Txhawb tsis-tus qauv loj customization, thiab cov txheej txheem yuav raug xaiv raws li ib tug galvanized thav duab, aluminium alloy ncej, thiab lwm yam.

3. Daim ntawv thov scenarios

Muaj filtration

Petrochemical: Siv rau kev sib cais, purification thiab concentration ntawm roj los yog kua, xws li distillation, nqus, evaporation thiab lwm yam txheej txheem.

Kev ua zaub mov: Lim impurities hauv kua lossis roj kom paub meej cov khoom purity.

Machinery manufacturing: Raws li cov khoom siv lim dej rau cov tshuab hydraulic thiab lubrication tshuab, nws tiv thaiv cov cuab yeej los ntawm kev puas tsuaj.

Cua purification

HVAC system: Siv rau thawj qhov pom ntawm cov cua txias hauv nruab nrab thiab cov khoom siv cua tshuab kom ntes cov pa hauv huab cua loj dua 10 microns.

Chav huv: Raws li cov cuab yeej ua ntej pom, nws txuas ntxiv lub neej kev pabcuam ntawm cov lim dej ua haujlwm siab.

Ib puag ncig kub kub: xws li metallurgical mines, painting rhiav, thiab lwm yam., lim plua plav thiab roj nyob rau hauv high-temperature gases.

Cov xwm txheej tshwj xeeb

Automobile manufacturing: siv rau cov roj pos huab pom nyob rau hauv cov khoom siv tshuaj pleev ib ce thiab cov xim pleev xim rau cov chav ua noj kom tsis txhob muaj kuab paug ntawm qhov chaw ua haujlwm.

Electronic technology: lim huv rhiav huab cua kom ntseeg tau tias tsis muaj plua plav ntau lawm ib puag ncig.

Kev kho mob thiab kev noj qab haus huv: siv rau qhov cua pom hauv cov khoom siv roj ntsha, zaub mov thiab dej haus kev lag luam, raws li cov qauv kev nyiam huv.

5. Cov txheej txheem tsim khoom

Cov txheej txheem weaving: stainless hlau hlau yog woven rau hauv ib tug mesh qauv los ntawm ib tug loom, thiab ces tshav kub kho los txhim kho lub zog thiab hardness.

Punching txheej txheem: siv lub xuas nrig ntaus lub qhov tsis tu ncua ntawm cov hlau phaj los tsim cov phaj zoo li cov qauv lim.

Sintering txheej txheem: ntau txheej hlau hlau mesh yog sintered ntawm qhov kub thiab txias los tsim cov qauv ntxeem tau los txhim kho lub zog thiab corrosion kuj.

Wave-shaped overlapping txheej txheem: txhuas ntawv ci los yog stainless hlau mesh yog dov los ua ib tug yoj duab, thiab ntau txheej yog cross-laminated thiab tsau rau tus ncej.

Kev kho deg: electroplating, pleev xim los yog txau cov hlau mesh los txhim kho corrosion kuj thiab zoo nkauj.