Stainless hlau hlau mesh rau roj teeb hmoov tshuaj ntsuam xyuas

Hauv kev tshuaj ntsuam xyuas roj teeb, kev xaiv thiab kev siv cov hlau tsis muaj steel hlau mesh yuav tsum tau ua ke nrog cov yam ntxwv ntawm cov khoom siv, cov yam ntxwv tshwj xeeb, cov txheej txheem weaving thiab cov kev ua haujlwm tiag tiag. Cov hauv qab no yog ib qho kev ntsuam xyuas tshwj xeeb:

1. Kev xaiv cov khoom siv

304 stainless hlau

Cov yam ntxwv: Zoo corrosion kuj, haum rau cov tshuaj lom neeg ib puag ncig, tus nqi qis.

Daim ntawv thov scenario: Ib qho yooj yim roj teeb tshuaj ntsuam xyuas, nyiam thaum tsis muaj qhov nruab nrab muaj zog corrosive.

316 stainless hlau

Cov yam ntxwv: Ntxiv molybdenum caij, corrosion kuj yog ho txhim kho, haum rau high humidity los yog tshuaj corrosive ib puag ncig.

Daim ntawv thov scenario: ntug hiav txwv dej, muaj zog acid thiab alkaline ib puag ncig, los yog kev tshuaj xyuas cov khoom zoo electrode nrog rau siab corrosion kuj.

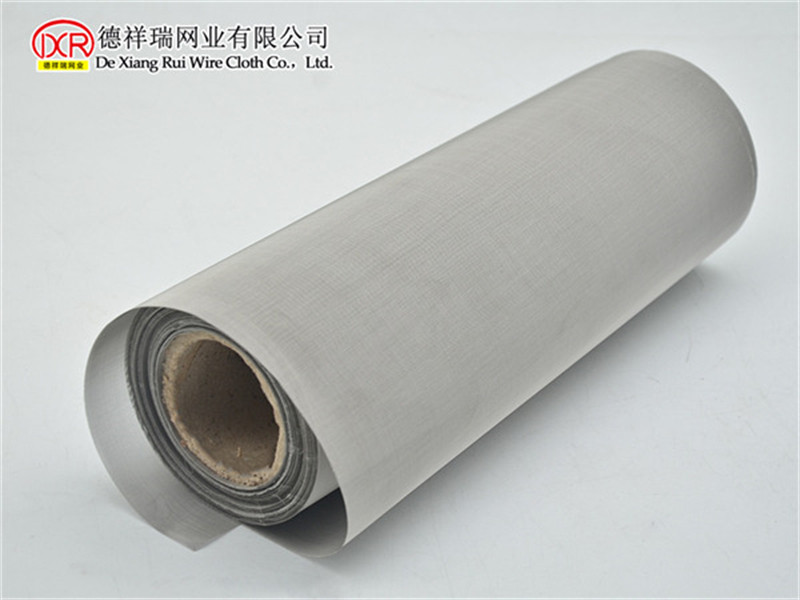

2. Cov lus qhia tshwj xeeb

Mesh naj npawb thiab aperture

200 mesh: aperture yog hais txog 0.075mm, haum rau kev tshuaj xyuas ua ntej kom tshem tawm cov khoom loj loj.

300 mesh: aperture yog hais txog 0.045mm, siv los kho qhov loj me thiab sib npaug kev tshuaj ntsuam xyuas thiab qhov tseeb.

400 mesh: Lub aperture yog hais txog 0.038mm, muab kev tshuaj ntsuam xyuas ntau dua thiab ua tau raws li qhov xav tau ntawm qhov loj me me.

Hlau txoj kab uas hla

Txoj kab uas hla ntawm cov xaim cuam tshuam rau lub zog thiab qhov tseeb ntawm qhov screen. Cov kab hlau zoo (xws li 0.038mm) tuaj yeem txhim kho qhov tseeb, tab sis qhov hnav tsis kam yuav tsum sib npaug; coarse hlau txoj kab uas hla (xws li 0.05mm) txhim khu lub zog, tab sis yuav txo tau qhov qhib tus nqi.

3. txheej txheem xaws

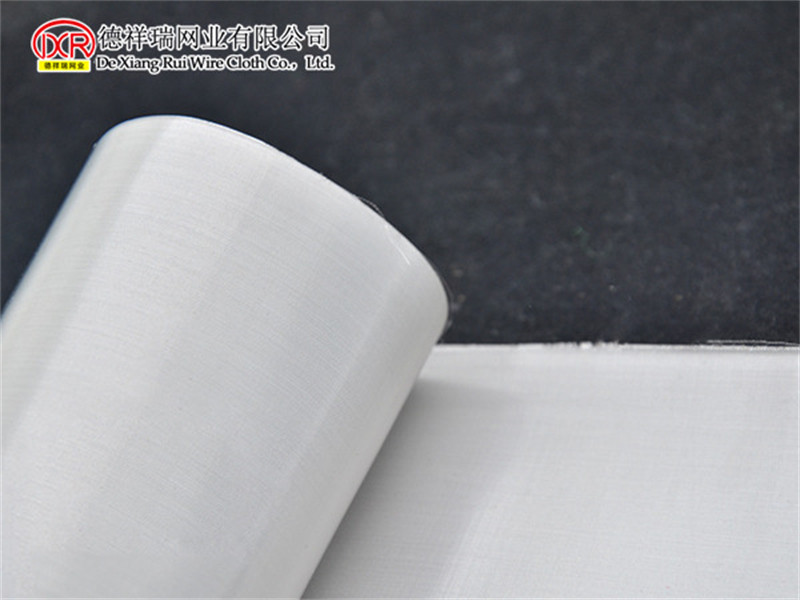

Plain weave

Structure: Lub warp thiab weft xov hlau yog interwoven vertically, lub mesh yog uniform, thiab lub zog yog siab.

Daim ntawv thov: Haum rau kev ntsuam xyuas ntxhib lossis cov kev cai dav dav.

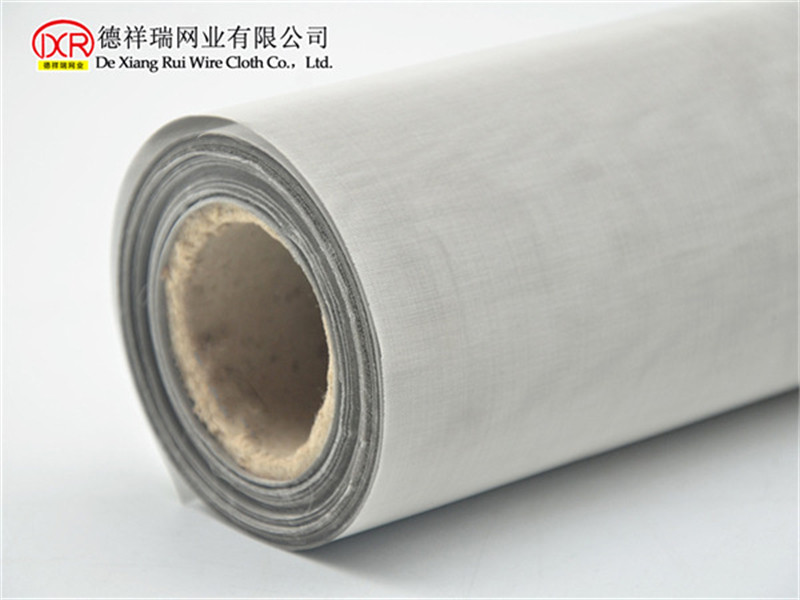

Twill weave

Structure: Cov xov hlau warp thiab weft yog interwoven obliquely, lub porosity yog siab dua, thiab kev tshuaj ntsuam xyuas tau zoo dua.

Daim ntawv thov: High-precision ntsuam xyuas, xws li zoo electrode khoom tsim.

4. Cov kev ua haujlwm tseem ceeb

Corrosion kuj

Thaum lub sij hawm tsim cov roj teeb, electrolytes thiab acid-base tshuaj yuav raug, thiab lub sij hawm ntev stability ntawm lub vijtsam yuav tsum tau xyuas kom meej.

Lub zog thiab hnav tsis kam

Thaum lub sij hawm kev tshuaj ntsuam xyuas, lub vijtsam yuav raug kev co thiab cov khoom cuam tshuam, thiab cov qauv yuav tsum ruaj khov kom ntev lub neej.

Yooj yim ntxuav

Qhov saum npoo yog du thiab tsis muaj cov fab tuag, uas txo cov hmoov seem thiab tsis txhob hla kev sib kis.

5. Daim ntawv thov scenarios thiab optimization

Multi-theem ntsuam xyuas system

Configuration: 200 mesh + 400 mesh ua ke, thawj qhov kev ntsuam xyuas ntxhib thiab tom qab ntawd tshuaj xyuas zoo, txhawm rau txhim kho kev ua haujlwm thiab raug.

Cov cuab yeej txhawb nqa

Ultrasonic vibrating npo: high-frequency vibration txo clogging, haum rau zoo particle soj ntsuam.

Lub tshuab nqus tsev noj mov: zam plua plav ya thiab txhim kho kev nyab xeeb.

Kev tswj xyuas

Kev tshuaj xyuas tsis tu ncua: saib xyuas kev hnav thiab thaiv, thiab hloov lossis huv si raws sijhawm.

Kev tu thiab tu: siv cov tshuaj ntxuav tshwj xeeb kom tsis txhob muaj xeb.

Post lub sij hawm: May-22-2025