300 mesh Photovoltaic cell printed screen board screen

300 mesh Photovoltaic cell printed screen board screen

The 300 Mesh Photovoltaic Cell Printed Screen Board is a precision-engineered, high-durability stainless steel screen designed specifically for depositing ultra-fine conductive electrode patterns onto silicon wafers and next-generation solar cells. It is a critical consumable component for manufacturers producing high-efficiency PERC, TOPCon, and HJT cells, as well as for R&D and pilot production lines focused on scalable perovskite and flexible organic photovoltaic (OPV) technologies.

What is Screen Printing?

Screen printing, also known as silk screening or silkscreen printing, is the process of transferring a stencilled design onto a surface using a mesh screen, ink, and a squeegee (a rubber blade). The basic process of screen printing involves creating a stencil on a mesh screen and then pushing the ink to create and imprint the design on the below surface. The most common surface used in screen printing is paper and fabric, but metal, wood, and plastic can also be used. It is a very popular technique because of many reasons, but the most compelling reason is the vast choice of colours that can be used.

Product Attributes

| Product Name | 300 Mesh Photovoltaic Cell Printed Screen Board |

| Primary Material | High-Grade Stainless Steel (e.g., Type 304/316 for corrosion resistance) |

| Mesh Count | 300 |

| Key Application | Front & Rear Side Metallization of Silicon Solar Cells (PERC, TOPCon, HJT) |

| Emerging Application | Scalable Deposition for Perovskite, Organic PV (OPV), and Flexible Solar Cells |

| Core Benefit | Enables high-precision, low-waste printing for increased cell efficiency and reduced production cost. |

| Industry Process | Precision Screen Printing for Photovoltaic Electrode Formation |

Maximizes Cell Efficiency

The fine 300-mesh structure enables the printing of thinner grid lines. This reduces the cell's surface area shaded by electrodes, allowing more photons to reach the active semiconductor layer, thereby directly increasing the current and final power conversion efficiency of the solar cell.

Optimizes Material Usage and Reduces Waste

Silver conductive paste is a major cost driver. Our screen ensures optimal paste transfer with minimal bleed-through or variation, leading to significant paste savings per cell and a reduction in material waste, contributing directly to a lower cost per watt.

Ensures Production Stability and Uptime

Manufactured from premium, fatigue-resistant materials, the screen offers exceptional durability and chemical resistance against abrasive pastes. This guarantees extended service life, consistent print quality over long production runs, and reduced frequency of screen changes, maximizing manufacturing line productivity and yield.

Facilitates Scalable Manufacturing

The screen's robust construction and consistent performance make it compatible with high-speed, automated printing lines, including those designed for roll-to-roll processing of flexible substrates. It supports the transition to more scalable, cost-effective manufacturing models essential for terawatt-scale solar adoption.

In the competitive landscape of photovoltaic (PV) manufacturing, achieving higher cell efficiency and lower production cost is paramount. Screen printing remains the dominant and most reliable metallization technique for applying conductive electrodes to solar cells, valued for its high throughput, simplicity, and excellent cost-performance ratio. Our 300 Mesh Photovoltaic Printing Screen is meticulously crafted to meet the exacting standards of modern PV production, serving as the foundational tool for precise, consistent, and low-waste paste deposition. It directly supports the industry's core mission: increasing power output while reducing the Levelized Cost of Electricity (LCOE).

This product is designed not only for today's mainstream crystalline silicon cells but also for the sustainable future of solar. Its precision is vital for printing the narrow, high-aspect-ratio grid fingers required for advanced cell architectures like TOPCon and Heterojunction (HJT), which demand finer lines to minimize shading losses and boost efficiency. Simultaneously, as the industry innovates, this screen is a key enabler for next-generation technologies. It is ideally suited for the scalable, roll-to-roll production of lightweight, flexible perovskite and organic solar cells, opening new markets for building-integrated photovoltaics (BIPV), portable electronics, and vehicle-integrated applications.

Product Application Summary

• Mainstream Silicon PV: Critical for manufacturing high-efficiency PERC, TOPCon, and HJT solar cells by printing precise front and rear-side contacts.

• Next-Generation Technologies: Enables scalable production of emerging perovskite solar cells (PSCs) and is compatible with flexible, thin-film, and organic PV (OPV) modules.

• Industry Driver: Supports the transition to high-throughput, low-cost manufacturing models like roll-to-roll (R2R) printing, which is vital for applications such as Building-Integrated Photovoltaics (BIPV).

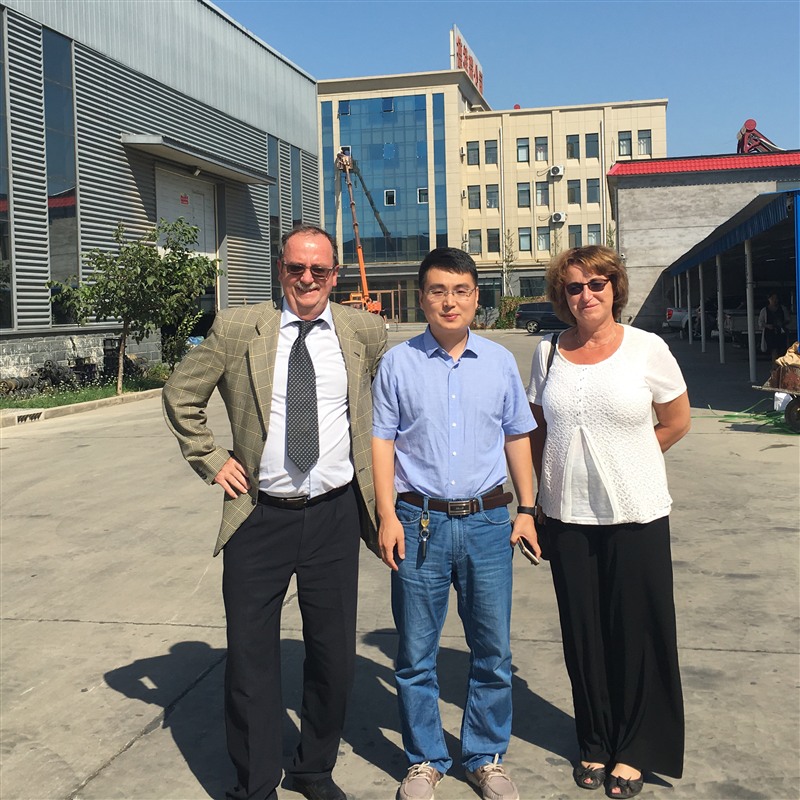

30+years production experience

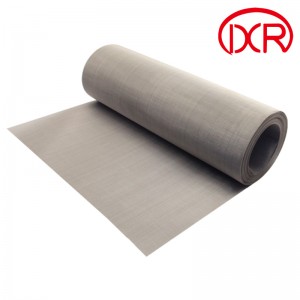

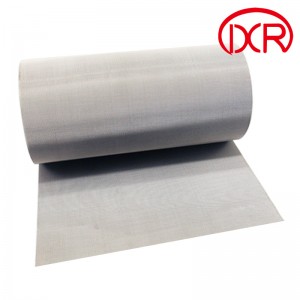

DXR Wire Mesh is a manufacturing & trading combo of wire mesh and wire cloth in the China.With a track record of over 30 years of business and a technical sales staff with over 30 years of combined experience.

Our Products

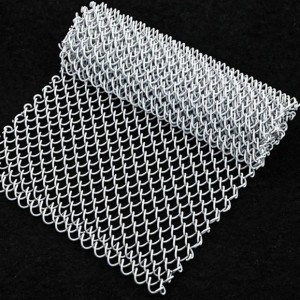

DXR's main products are stainless steel wire mesh, filter wire mesh, titanium wire mesh,copper wire mesh, plain steel wire mesh and all kinds of mesh further-processingproducts. Total 6 series, about thousand types of products, widely applied forpetrochemical, aeronautics and astronautics, food, pharmacy, environmentalprotection, new energy, automotive and electronic industry.

In 1988,DeXiangRui Wire Cloth Co, Ltd. was foundedannual value of production is about 30 million US dollars.of which 90% of products delivered to more than 50 countries and regions. DXR brand as a famous brand inHebei Province has been registered in 7 countries aroundthe world for trademark protection.

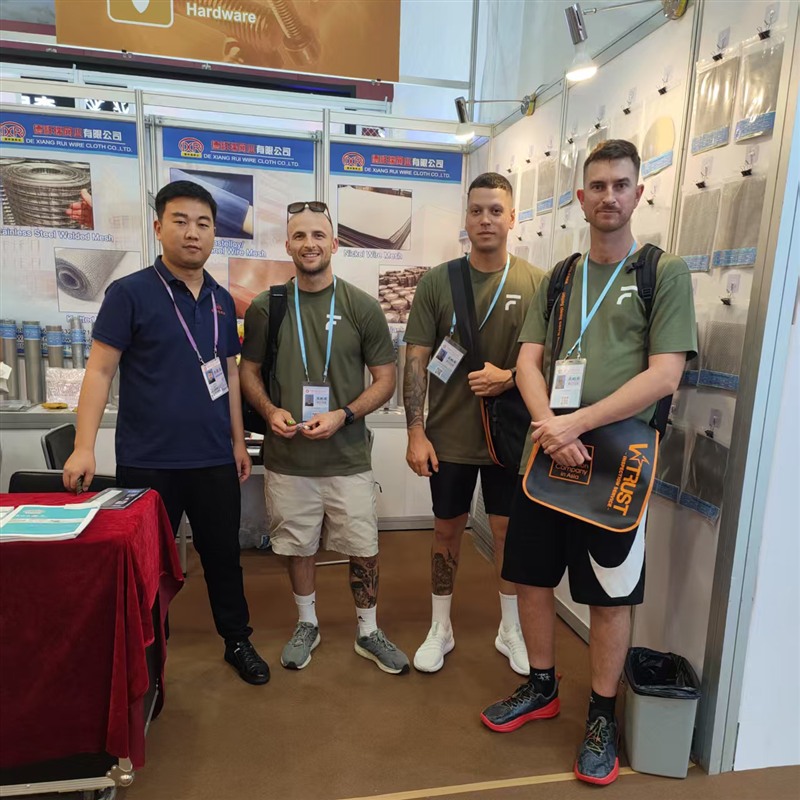

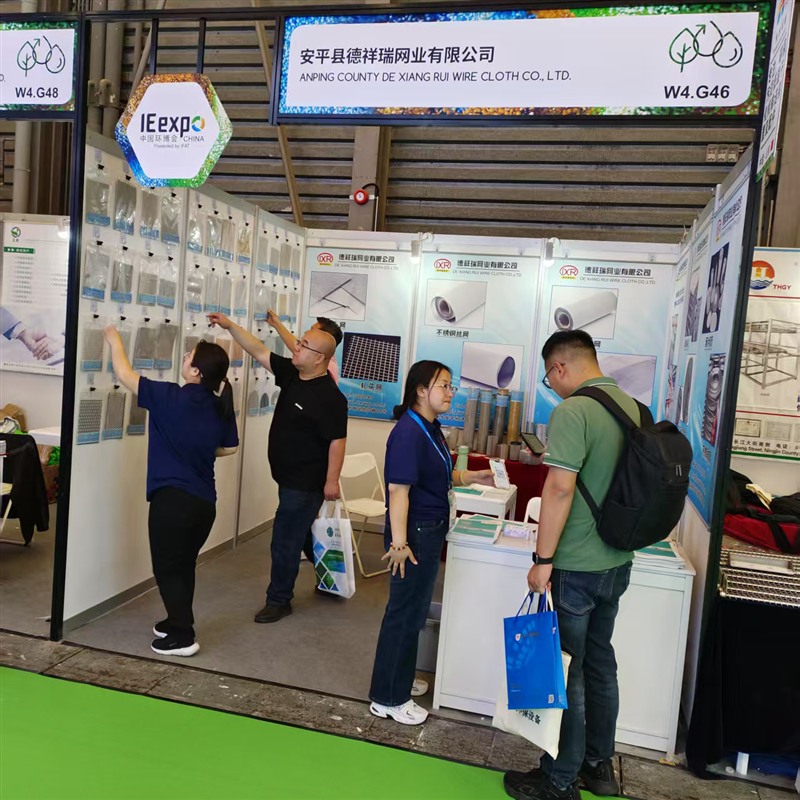

Customers and Exhibitions

Inside The Factory

Workshop

Production Machine

FAQ

Q1: Is it all right to make customer's own brand name?

A: Yes, we offer OEM service.

Q2: Are you a manufactuer or trading company?

A: We are a professional manufacturer since 1988.

Q3: Can you do the design for us?

A: Yes,Both design and customization are available

Q4: How can I get a sample to check your quality?

A: Please send us an email to sales88@china-wiremesh.net or contact us through this website. We will arrange samples via DHL, FedEx, UPS etc.

Q5: Is the sample free,and How long can I expect to get the sample?

A: Although we support free sample, you need pay the freight.It depends on your address how long it will take to receive it. We can do all the sample in 2 days

Q6: Packaging & Shipping:

A: "Water-proof paper,plastic film, wooden cases or pallets outside.

By sea, train, sea and air. "

Q7: What about the lead time for mass production?

A: Common specifications within 30 days

Q8: Where is your loading port?

A: Tianjin, Qingdao

Q9: How long is the delivery period of the product?

A: 2-30 days

Q10: What quality certifications do you have?

A: CE, ISO 9001:2015, SGS