Factory Free sample Woven Screen - Galvanized Wire Mesh – DXR

Factory Free sample Woven Screen - Galvanized Wire Mesh – DXR Detail:

Galvanized Wire Mesh

Galvanized Wire Mesh is made of galvanized iron wire. It is also can be made of iron wire then zinc coating galvanized also can coated PVC. Galvanized Wire Mesh is commonly used as insect screening and sieves, industries, and constructions.

Galvanizing can occur either before or after wire mesh is manufactured – both in woven form or welded form. Galvanized before woven wire mesh or galvanized before welded wire mesh indicates the individual wires, themselves, used to manufacture the mesh have been galvanized before the mesh is woven or welded. Depending on the mesh (or opening size) and diameter wire, this is usually the less expensive option, especially if custom manufacturing is required.

Galvanized after woven and galvanized after welded wire mesh is exactly as it sounds. The material is manufactured, normally in carbon or plain steel, and is often placed in a galvanizing tank, thereby producing a galvanized after woven or welded specification. Generally speaking, this option is more expensive, depending on availability and other variables, but does offer a higher level of corrosion resistance. This added level of corrosion resistance is most noticeable at the joint or intersection of galvanized after welded wire mesh specification.

Weave Type

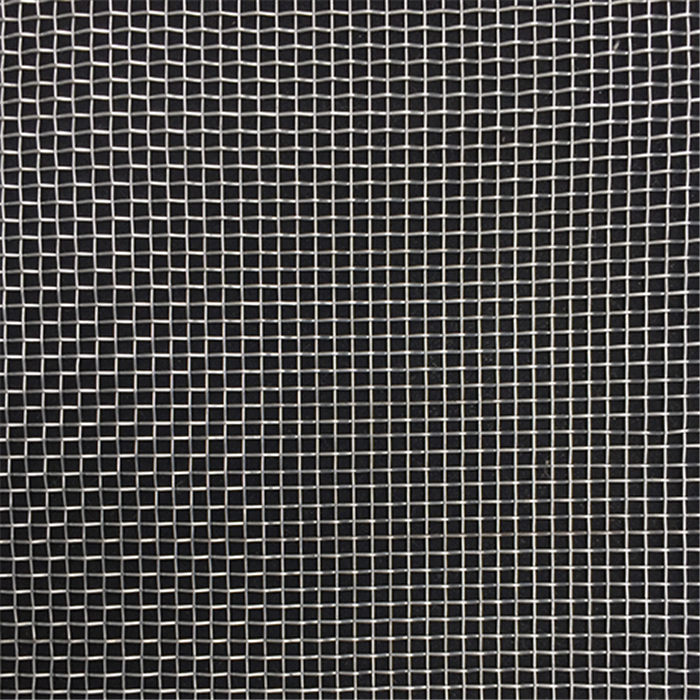

Hot-dip galvanized after weaving wire mesh

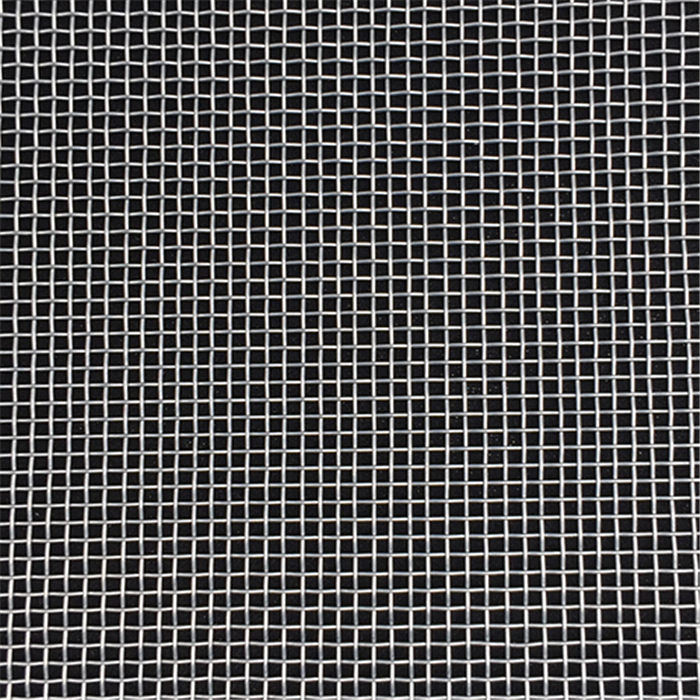

Hot-dip galvanized before weaving wire mesh

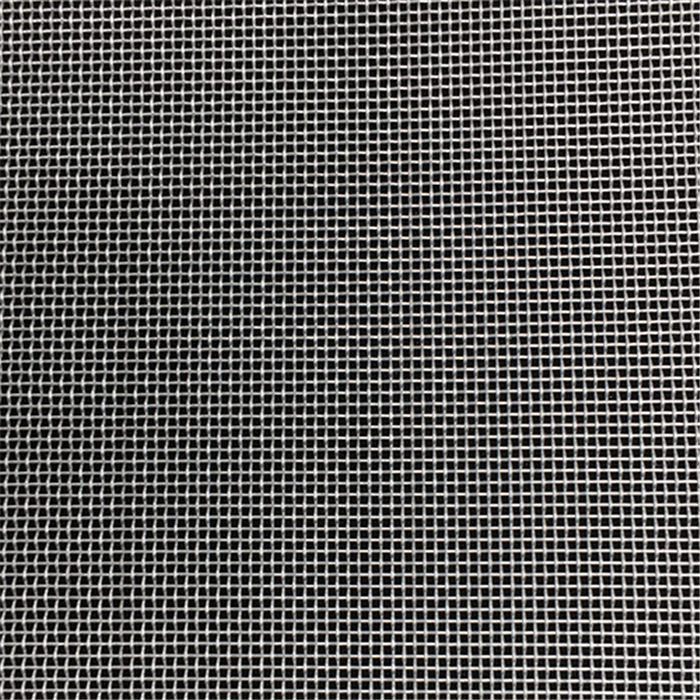

Electric galvanized before weaving wire mesh

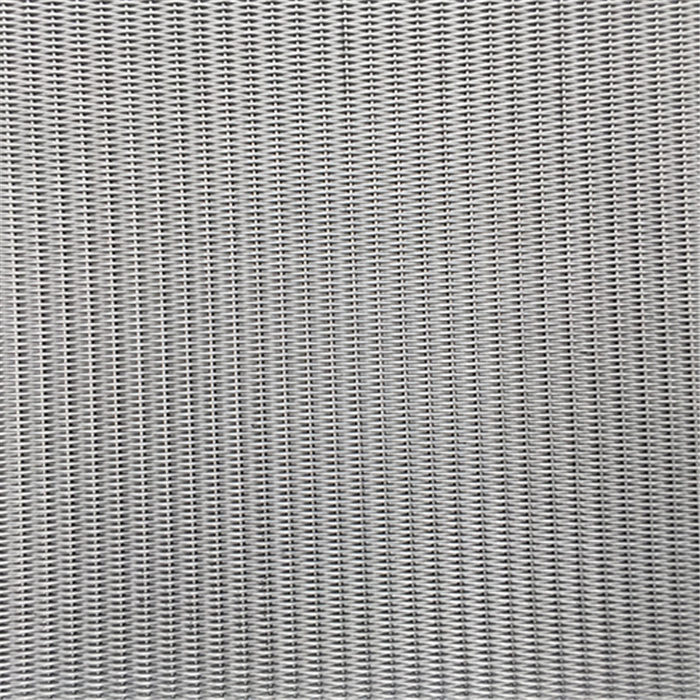

Electric galvanized after weaving wire mesh

Crimped square woven wire mesh

Basic Info

Woven Type: Plain Weave

Mesh: 1.5-20 mesh, To accurately

Wire Dia.: 0.45-1 mm, small deviation

Width: 190mm, 915mm, 1000mm, 1245mm to 1550mm

Length: 30m, 30.5m or cut to length minimum 2m

Hole shape: Square Hole

Wire Material: Galvanized wire

Mesh Surface: clean, smooth, small magnetic.

Packing: Water-Proof, Plastic Paper, Wooden Case, Pallet

Min.Order Quantity: 30 SQM

Delivery Detail: 3-10 days

Sample: Free Charge

|

Mesh |

Wire Dia.(inches) |

Wire Dia.(mm) |

Openging(inches) |

Openging(mm) |

|

1.5 |

0.039 |

1.000 |

0.627 |

15.933 |

|

2 |

0.039 |

1.000 |

0.461 |

11.700 |

|

2 |

0.236 |

6.000 |

0.264 |

6.700 |

|

3 |

0.024 |

0.600 |

0.310 |

7.867 |

|

3 |

0.063 |

1.600 |

0.270 |

6.867 |

|

4 |

0.016 |

0.400 |

0.234 |

5.950 |

|

4 |

0.059 |

1.500 |

0.191 |

4.850 |

|

5 |

0.014 |

0.350 |

0.186 |

4.730 |

|

5 |

0.059 |

1.500 |

0.141 |

3.580 |

|

6 |

0.014 |

0.350 |

0.153 |

3.883 |

|

6 |

0.059 |

1.500 |

0.108 |

2.733 |

|

8 |

0.012 |

0.300 |

0.113 |

2.875 |

|

8 |

0.047 |

1.200 |

0.078 |

1.975 |

|

10 |

0.012 |

0.300 |

0.088 |

2.240 |

|

10 |

0.047 |

1.200 |

0.053 |

1.340 |

|

12 |

0.012 |

0.300 |

0.072 |

1.817 |

|

12 |

0.047 |

1.200 |

0.036 |

0.917 |

|

14 |

0.008 |

0.200 |

0.064 |

1.614 |

|

14 |

0.028 |

0.700 |

0.044 |

1.114 |

|

16 |

0.008 |

0.200 |

0.055 |

1.388 |

|

16 |

0.024 |

0.600 |

0.039 |

0.988 |

|

18 |

0.008 |

0.200 |

0.048 |

1.211 |

|

18 |

0.018 |

0.450 |

0.038 |

0.961 |

|

20 |

0.008 |

0.200 |

0.042 |

1.070 |

|

20 |

0.018 |

0.450 |

0.032 |

0.820 |

Product detail pictures:

Related Product Guide:

Cooperation

go on to boost, to be certain item quality in line with market and buyer standard demands. Our firm has a excellent assurance procedure happen to be established for Factory Free sample Woven Screen - Galvanized Wire Mesh – DXR , The product will supply to all over the world, such as: Belarus, Portugal, Canada, Now, we professionally supplies customers with our main merchandise And our business is not only the "buy" and "sell", but also focus on more. We target to be your loyal supplier and long-term cooperator in China. Now, We hope to be the friends with you.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.