mining screen mesh

Mining screen is a metal mesh structure element used for screening and filtering. It is widely used in mining, coal, petroleum and other industries. The following is an introduction from the aspects of material, structure, performance, application and maintenance:

1. Material classification

Metal material

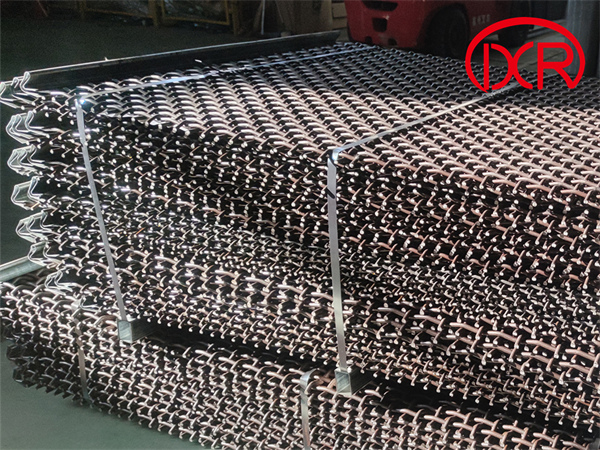

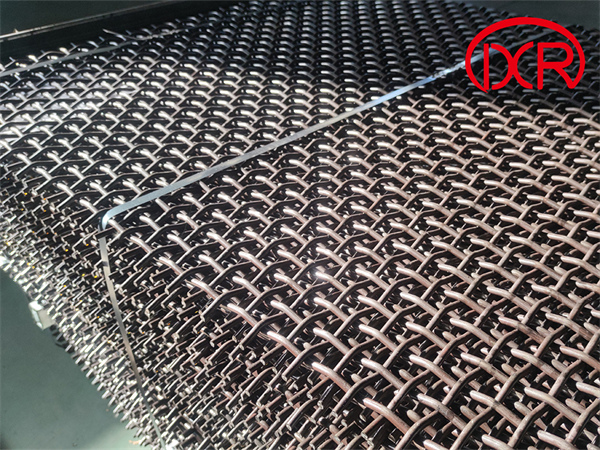

High manganese steel screen: It is woven with manganese steel wire with a wire diameter of 1.6mm~12mm. The warp and weft overlap points are not prominent, the screen surface is flat, the force is uniform, and it has good plasticity and toughness. When subjected to strong impact and friction, the surface is hardened due to plastic deformation, and the hardness value can be increased to above HRC60. It has high wear resistance, and the internal plasticity and toughness are still high. The service life can reach 4~8 times that of ordinary screens. It is mostly used in large-scale mining industries.

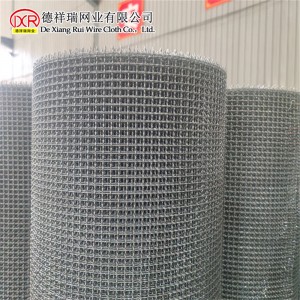

Stainless steel screen: The main materials are 201, 302, 304, 304L, 316, etc., with good acid, alkali and rust resistance, high strength, strong tensile strength, toughness and wear resistance, durable, high temperature oxidation resistance (304 stainless steel screen nominal temperature resistance is 800℃, 310S stainless steel screen nominal temperature resistance can reach 1150℃), room temperature processing (easy plastic processing, making the use of stainless steel screen diversified), high finish (no surface treatment is required, maintenance is convenient and simple), etc., often used for screening and filtering under acid and alkaline environment conditions, as well as mud nets in the petroleum industry, as screens in the chemical fiber industry, etc.

Welded screen: It is welded from high manganese steel raw materials, using small current, discontinuous welding, or cooling while welding with water, and the welding rods are high manganese steel welding rods or austenitic stainless steel welding rods.

Non-metallic materials

Polyurethane screen: Polyurethane itself has a very high elastic modulus, high strength to absorb impact, high wear resistance, and high tensile strength. Therefore, its bearing capacity is relatively high, which is more than 2.5 times that of rubber screen plates. Its service life is 8~10 times higher than that of ordinary metal screen plates, 3 times that of stainless steel screen surfaces, and 3.9 times that of natural rubber. It is the screen surface material with better wear resistance at present. Its production material belongs to high molecular organic elastomer, which has excellent wear resistance, flexibility resistance, and large bearing capacity. It has undergone special treatment to ensure that it will never delaminate under long-term alternating loads, and is more suitable for screening of washed materials.

2. Structural form

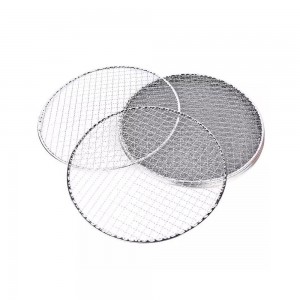

Woven mesh: woven from metal wire, with a large opening rate, which can reach 75% of the total screen area, but the strength is relatively low, and it is often used for screening fine particle materials.

Steel plate mesh: strong, long service life, but relatively low opening rate, generally used for screening of medium-sized materials.

Punching screen: Use a punch to punch out the target pattern in the plate to be processed. It is generally made of stainless steel, aluminum plate, hot and cold steel plate, copper plate, PVC plate film and other materials. There are many hole types, including long holes, square holes, round holes, hexagonal holes, fish scale holes, stretched special-shaped holes, etc. It has the characteristics of light weight, non-slip, beautiful appearance, good filtering performance, etc. It is often used in environmental noise control barriers in transportation and municipal facilities, grinding screens, mine screens, I-shaped screens, etc. for mines.

3. Performance characteristics

High screening rate: It can effectively separate materials of different particle sizes and improve screening efficiency.

Wear-resistant and corrosion-resistant: It can adapt to complex screening environments, reduce replacement frequency, and reduce enterprise costs.

Anti-slip and vibration-resistant: It remains stable during the screening process, reducing material blockage and screen damage.

Strong elasticity and toughness: It has a certain elasticity and deformation capacity, and can adapt to ores of different particle sizes and shapes.

No close together: The screen remains flat during the screening process, and no close together phenomenon occurs, ensuring the screening effect.

4. Application Field

Mining screens are suitable for a variety of mining equipment and process flows, such as crushers, mills, concentrators, etc., which can achieve ore screening, grading and selection.

5. Maintenance

Regular inspection of the screen: It is necessary to regularly check whether its surface is damaged or deformed, and replace the damaged screen in time.

Cleaning the screen: The vibrating screen will generate a lot of dust during operation, and the screen needs to be cleaned regularly to keep it clean and avoid clogging the screen holes.

Improve the diversion capacity: If the middle of the screen is severely worn, the diversion capacity can be improved or the middle of the screen can be raised to an upward arc.