EcoOne Technology Redefines Energy Efficiency with 20% Savings

The introduction of single-motor designs has emerged as a game-changing innovation in centrifuge basket technology. The EcoOne system, which integrates pusher and drive functions into a single motor assembly, has demonstrated a 20% reduction in energy consumption compared to conventional dual-motor configurations. This breakthrough comes at a critical time as European industrial energy costs remain 35% higher than pre-2022 levels, according to Eurostat data. The unified motor design not only cuts electricity expenses but also simplifies mechanical layouts, reducing wear-prone components by 40% and extending maintenance intervals from 4,000 to 8,000 operating hours.

“Our pharmaceutical clients in Germany are reporting payback periods of less than 12 months after upgrading to EcoOne-equipped baskets,” noted a technical sales director at a leading European distributor. “The dual benefit of energy savings and reduced downtime is creating strong demand across chemical and food sectors as well.” This efficiency gain is particularly impactful in continuous operation scenarios, where a mid-sized chemical plant processing 50,000 liters daily can achieve annual savings exceeding €75,000.

AI-Powered Systems Deliver Precision Separation and Predictive Maintenance

Artificial intelligence has transformed centrifuge basket performance through real-time adaptive control systems. Multi-spectral sensor arrays now monitor material characteristics with unprecedented precision, adjusting rotational speeds (±0.1 RPM) and separation parameters dynamically based on particle size distribution and moisture content. This technology has提升 API recovery rates in pharmaceutical applications from 95% to 99.97%, while reducing product loss by an average of 2.3% per batch.

Predictive maintenance algorithms represent another significant advancement, analyzing vibration频谱 (0-10 kHz bandwidth) and temperature differentials to forecast potential failures up to two weeks in advance. A case study from a U.S. biopharmaceutical facility showed that implementing AI monitoring reduced unplanned downtime by 68% and extended basket lifespan by 35% compared to traditional maintenance schedules. These systems, compliant with FDA 21 CFR Part 11, provide detailed operational logs and performance analytics that help distributors demonstrate tangible value to end-users.

Stainless Steel 304/316L Dominates Material Innovation

Material science advancements have enabled centrifuge baskets to meet increasingly stringent industry requirements. Stainless steel 304 and 316L now dominate production, offering superior corrosion resistance (PREN ≥ 34 for 316L) and compliance with pharmaceutical GMP standards. The introduction of laser-perforated titanium alloy screens with gradient润湿 coatings has further enhanced performance, achieving 99.97% solid截留率 in fine chemical applications.

For extreme environments, specialized alloys are gaining traction. Hastelloy C-276 baskets are now specified for mineral acid processing, while duplex 2205 stainless steel has become the material of choice for offshore drilling mud systems, where chloride resistance is critical. These material innovations have expanded application boundaries, allowing centrifuge baskets to operate reliably in temperatures ranging from -196°C to 400°C and handle pH extremes from 1 to 14.

“The move to 316L has been transformative for our food processing clients,” explained a technical specialist at a North American distribution firm. “The Ra ≤ 0.2μm surface finish eliminates bacterial harborage points, while the material’s durability reduces replacement frequency from quarterly to bi-annually in tomato paste applications.”

Pharmaceutical Sector Drives Precision Engineering Demand

The pharmaceutical industry remains the most dynamic segment for advanced centrifuge baskets, with biopharmaceutical production alone requiring a 12% annual increase in separation capacity, according to BioPlan Associates’ 2025 report. The latest baskets feature ultra-smooth 316L surfaces with electropolished finishes (Ra ≤ 0.1μm) and integrated CIP spray nozzles that reduce cleaning cycle times by 40%. These designs comply with EHEDG Guideline 42 standards for hygienic equipment, critical for monoclonal antibody (mAb) production where cross-contamination risks must be eliminated.

In vaccine manufacturing, the gentle handling capabilities of new basket designs have become essential. The Gentle Feeder™ system, which minimizes shear forces during separation, has increased cell viability rates from 85% to 95% in mRNA vaccine production lines. This advancement directly contributes to yield improvements of 6.08% per batch, translating to millions in additional revenue for biopharmaceutical producers.

Food Processing Innovations Address Safety and Efficiency Demands

Food and beverage processors are adopting specialized centrifuge baskets to meet evolving consumer demands and regulatory requirements. The dairy industry, in particular, has benefited from wedge wire designs with 0.25mm slot precision, which achieve 99.9% fat separation efficiency while reducing water usage by 30% compared to traditional membrane filtration. These baskets now process over 60% of Europe’s milk supply, according to EU Dairy Association statistics.

For high-viscosity applications like fruit purees and sauces, variable-pitch spiral baskets have become industry standards. These designs feature adjustable螺距 (120mm front/80mm rear) that can be optimized for specific products, increasing throughput by 25% for tomato processing and reducing energy consumption by 18% in starch production. A major U.S. food processor recently reported annual savings of $420,000 after retrofitting their entire line with these specialized baskets.

Wastewater Treatment Sector Sees Rapid Adoption of High-Capacity Designs

The global push for water sustainability has driven significant innovation in wastewater treatment baskets. Municipal facilities upgrading to advanced designs are achieving solids recovery rates of 99% compared to 96% with older technology, according to the Water Environment Federation. The G3 series decanter baskets, featuring extended bowl lengths and optimized scroll geometries, have enabled facilities like Atlanta’s T.Z. Osborne Water Reclamation Plant to double throughput while reducing polymer usage by 17%.

In industrial applications, the shift to ceramic-lined baskets has dramatically improved durability in abrasive sludge environments. A case study from a German chemical plant showed that alumina ceramic coatings increased basket lifespan from 6 months to 3 years in paint sludge separation processes, reducing replacement costs by 70%. These advancements come as wastewater treatment regulations tighten worldwide, with the EU’s Urban Waste Water Treatment Directive requiring 80% sludge dryness by 2027.

Regional Demand Patterns Create Targeted Opportunities for Distributors

Europe maintains its position as the largest market for advanced centrifuge baskets, with Germany alone accounting for 28% of global demand. The region’s strict environmental regulations (REACH, CE PED) and pharmaceutical manufacturing dominance drive premium pricing, with average basket values 22% higher than Asia-Pacific counterparts. Northern European countries show particular strength in food processing applications, while Central Europe leads in chemical sector adoption.

North America is experiencing robust growth at 5.2% CAGR, fueled by biopharmaceutical expansion and wastewater infrastructure upgrades. The U.S. pharmaceutical sector invested $12.7 billion in manufacturing capacity in 2024, creating strong demand for GMP-compliant baskets. Mexico’s growing food processing export industry is emerging as a key market, with annual growth exceeding 8% for specialized fruit and vegetable processing baskets.

Asia-Pacific presents the fastest growth trajectory, projected to reach $2.1 billion by 2032 at a 7.2% CAGR. China dominates regional production, accounting for 86% of Asia-Pacific output, while India’s pharmaceutical sector is driving import growth at 15% annually. Southeast Asian food processors are rapidly adopting stainless steel 316L baskets to meet EU export standards, creating opportunities for distributors offering technical support and certification assistance.

Custom Engineering Meets Niche Application Requirements

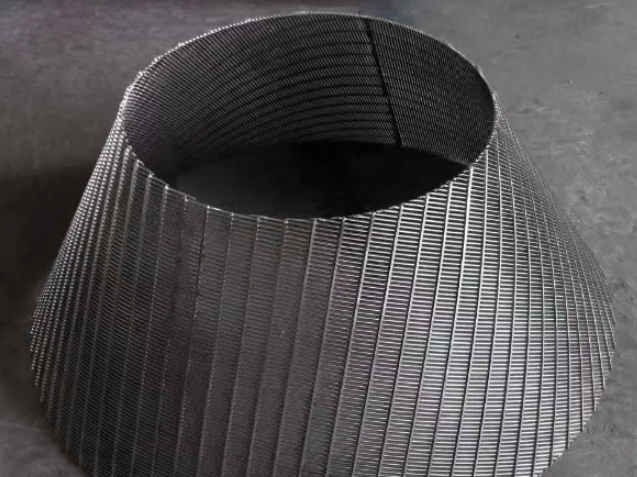

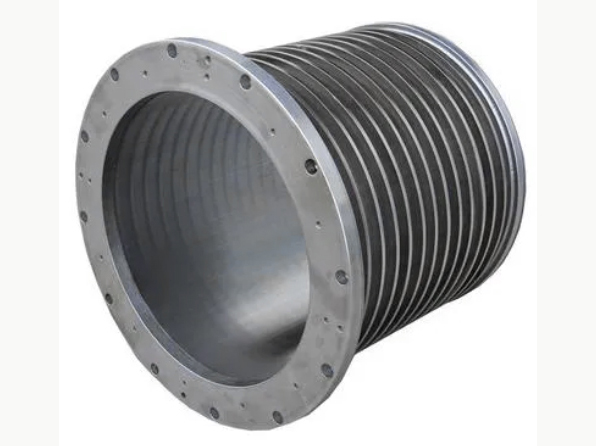

The most significant trend in centrifuge basket development is the shift toward application-specific engineering. Manufacturers now offer baskets with slot sizes ranging from 0.1mm to 1.2mm, optimized for everything from nanoparticle separation to coarse mineral processing. Conical designs with 10-22° angles are becoming standard for dewatering applications, while cylindrical baskets dominate liquid clarification processes.

“Distributors who can provide custom-engineered solutions are capturing premium margins,” observed an industry analyst. “We’re seeing specialized baskets for niche applications like lithium battery recycling and plant-based protein processing command 30-40% price premiums over standard models.” Recent innovations include baskets with replaceable wear zones, which reduce replacement costs by 50% in abrasive mining applications, and hermetically sealed designs for toxic chemical processing that eliminate vapor emissions.

As the centrifuge basket market continues to evolve, distributors must stay ahead of technological advancements while understanding regional application nuances. The convergence of energy efficiency, smart automation, and material science has created a dynamic marketplace where the ability to educate customers on total cost of ownership—rather than just upfront price—will separate successful distributors from the competition. With industries worldwide upgrading aging equipment and investing in sustainable technologies, the next five years promise significant growth for those positioned to deliver these revolutionary separation solutions.

Post time: Nov-06-2025