In the pursuit of innovative, sustainable, and visually striking building designs, perforated metal has emerged as a cornerstone material for ventilated facades. Combining functionality with artistic expression, these metal panels are transforming urban landscapes while addressing critical challenges like energy efficiency, thermal regulation, and environmental resilience.

Why Perforated Metal Dominates Ventilated Facade Systems

Ventilated facades, also known as double-skin facades, rely on perforated metal panels to balance aesthetics and performance. Here’s why architects and engineers favor this material:

Energy Efficiency and Thermal Control

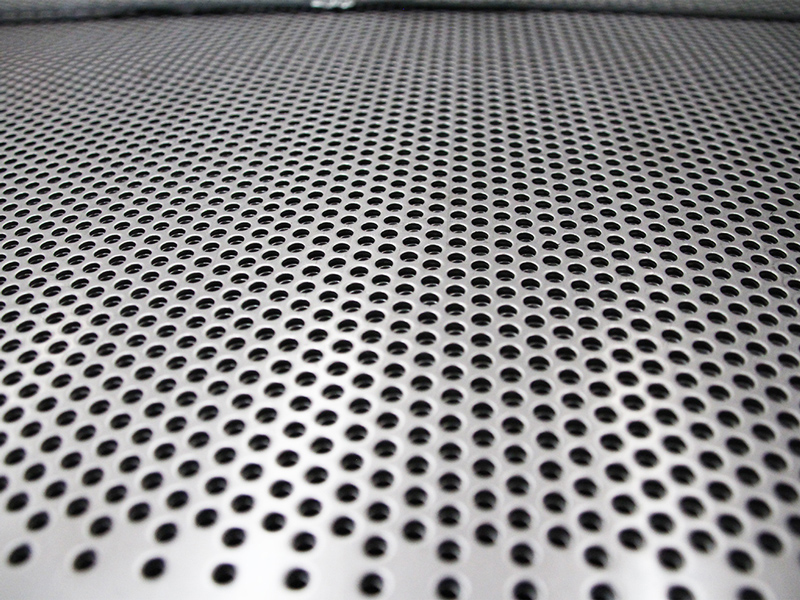

Perforated metal facades act as a dynamic thermal buffer. The micro-perforations (ranging from 1–10 mm in diameter) allow airflow between the exterior cladding and the building envelope, reducing heat absorption by up to 30% (as per a 2022 study by the International Journal of Sustainable Building Technology). This passive cooling effect slashes HVAC energy consumption, aligning with LEED and BREEAM certification goals.

Design Versatility

Available in materials like aluminum, stainless steel, and Corten steel, perforated panels can be customized with patterns, densities, and finishes (powder-coated, anodized, or patinated). Iconic projects like the Museo Soumaya in Mexico City showcase intricate floral perforations, while the Apple Store in Chicago uses minimalist circular perforations for a sleek, modern look.

Durability in Harsh Environments

High-grade metals resist corrosion, UV degradation, and extreme weather. For example, aluminum-magnesium alloy panels used in coastal projects (e.g., the V&A Dundee Museum in Scotland) withstand salt spray without compromising structural integrity.

Acoustic Performance

Strategic perforation patterns absorb and diffuse sound waves, reducing urban noise pollution. The Elbphilharmonie Concert Hall in Hamburg employs perforated aluminum panels to achieve optimal acoustics while maintaining visual transparency.

Global Case Studies: Perforated Metal Facades in Action

The Shard, London

Europe’s tallest skyscraper features stainless steel perforated panels that reflect sunlight, minimizing glare and solar heat gain. The design reduces the building’s cooling load by 25%, earning it a RIBA Sustainable Design Award.

Shanghai Natural History Museum, China

Corten steel panels with organic, cell-like perforations mimic natural textures, blending the structure with its ecological surroundings. The facade’s self-shading design cuts energy use by 40% compared to conventional cladding.

One Central Park, Sydney

This mixed-use tower uses parametric-designed aluminum panels with varying perforation densities to optimize daylight penetration and ventilation. The system contributed to the project’s 6-Star Green Star Rating.

Innovations in Perforated Metal Technology

Modern fabrication techniques are pushing the boundaries of ventilated facades:

Parametric Design: AI-driven tools optimize perforation layouts for site-specific solar and wind conditions.

Photovoltaic Integration: Panels embedded with solar cells (e.g., perforated BIPV modules) generate renewable energy while maintaining airflow.

Smart Coatings: Nano-coatings like hydrophobic layers repel dust and rainwater, ensuring low-maintenance facades.

Post time: Jun-11-2025