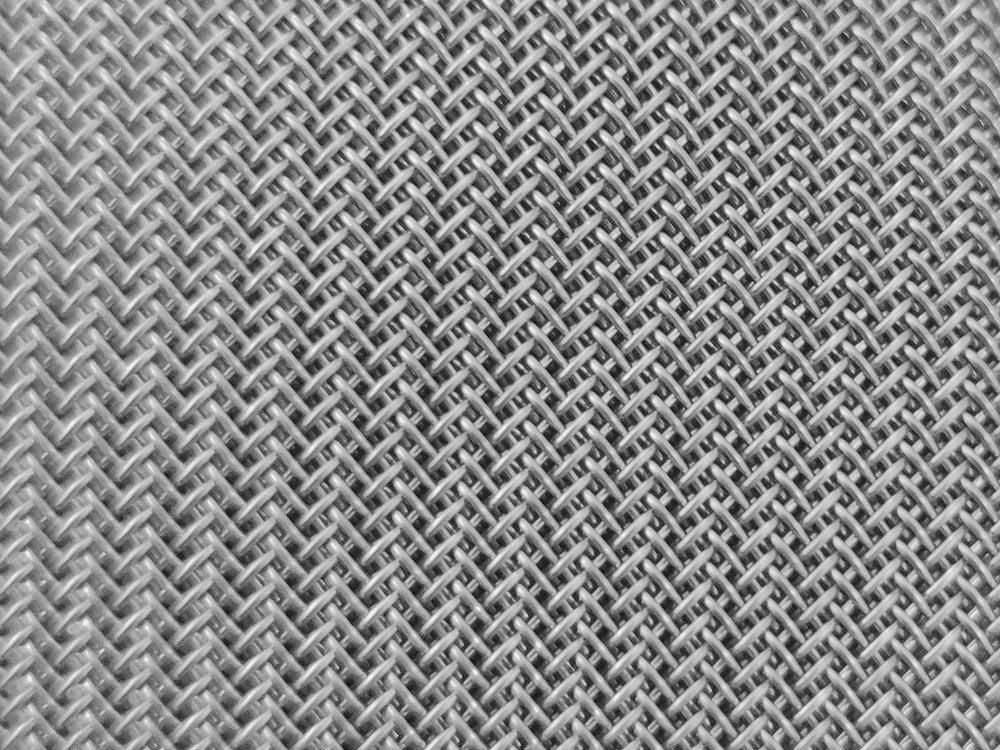

In recent years, stainless steel twill wire mesh has gained wider use in industrial filtration as manufacturers and end users seek more reliable and long-lasting filtration materials. Compared with conventional wire mesh structures, the twill weave design provides improved mechanical strength and allows for finer mesh counts without compromising stability.

The growing demand for efficient filtration in industries such as chemical processing, petroleum refining, food production, and environmental protection has contributed to the increased application of stainless steel twill wire mesh. Its uniform openings and smooth surface help ensure consistent filtration accuracy while reducing material loss during operation.

Material selection also plays a key role in this trend. Stainless steel grades such as 304 and 316 offer strong resistance to corrosion, oxidation, and chemical exposure, enabling the mesh to perform reliably in harsh working environments. These characteristics are particularly important in continuous filtration systems where long service life and minimal maintenance are required.

Manufacturers have responded to market demand by improving weaving precision and expanding customization options. Adjustments in wire diameter, mesh count, and material composition allow stainless steel twill wire mesh to meet diverse filtration requirements across different industries and operating conditions.

As industrial processes continue to emphasize efficiency, quality control, and environmental compliance, stainless steel twill wire mesh is expected to remain a key filtration material. Its combination of durability, precision, and adaptability supports its expanding role in modern industrial filtration systems.

Post time: Feb-05-2026