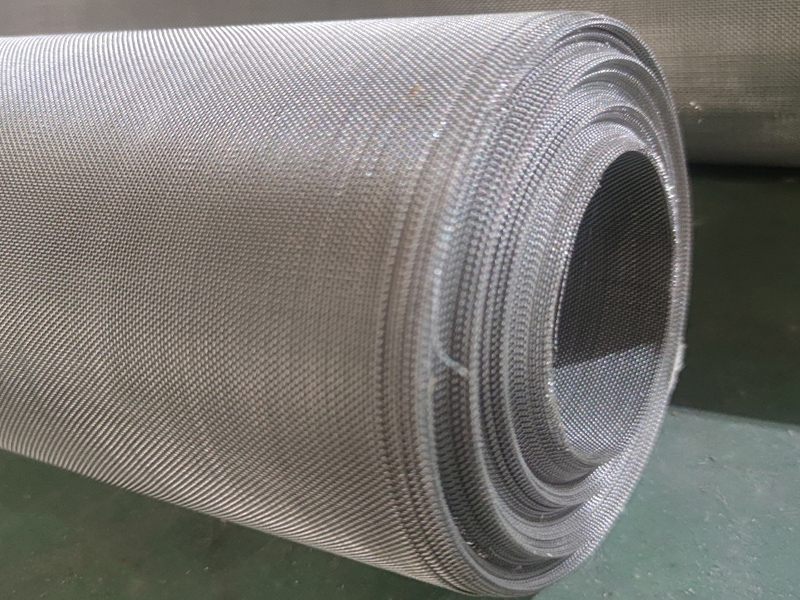

In chemical processing plants, where aggressive chemicals, extreme temperatures, and high-pressure environments are commonplace, stainless steel wire mesh stands as a critical component. Renowned for its corrosion resistance, mechanical strength, and filtration efficiency, this material is vital for maintaining operational safety and efficiency.

Why Stainless Steel Wire Mesh Excels in Chemical Environments

Stainless steel wire mesh is engineered to meet the rigorous demands of chemical processing through three key attributes:

1. Superior Corrosion Resistance: Grades like 316L and 904L stainless steel resist chloride ions, acids (e.g., sulfuric, hydrochloric), and alkaline solutions, ensuring longevity even in harsh conditions.

2. High-Temperature Stability: Withstanding temperatures up to 1,600°F (870°C), stainless steel mesh maintains structural integrity in heat exchangers or reactor systems.

3. Precision Filtration Capability: Tightly controlled aperture sizes (e.g., 10–500 microns) and weave patterns (plain, twill, or Dutch weave) enable efficient separation of particulates from gases and liquids.

Key Applications in Chemical Processing

1. Gas and Liquid Filtration

Stainless steel mesh filters remove contaminants from process streams. For instance, sintered multilayer mesh is used in catalyst recovery systems to trap fine particles while allowing high flow rates, complying with ASME BPE standards for hygienic design.

2. Reactor Vessel Protection

Mesh screens installed inside reactors prevent solid byproducts from damaging agitators. A 2023 case study by Chemical Engineering Journal showed that 316L stainless steel mesh liners reduced unplanned downtime by 40% in a PVC production facility.

3. Distillation Column Packing

High-surface-area mesh structured packing improves vapor-liquid contact, boosting separation efficiency. Materials like 304 stainless steel are preferred for ethanol distillation due to their resistance to organic acids.

4. Safety Barriers and Ventilation

Explosion-proof mesh enclosures for pumps or valves, compliant with ATEX Directive 2014/34/EU, prevent sparks while allowing airflow to mitigate gas buildup.

Industry Standards and Material Innovation

Leading manufacturers adhere to global certifications to ensure reliability:

- ASTM A480: Specifies surface finish and dimensional tolerances for stainless steel sheets used in mesh production.

- ISO 9001: Guarantees quality control in fabrication processes, critical for mesh used in pharmaceutical or food-grade chemical applications.

Conclusion

Stainless steel wire mesh is indispensable in chemical processing, offering unmatched corrosion resistance, thermal stability, and filtration precision. By aligning with industry standards and leveraging advanced manufacturing techniques, it ensures safe, efficient, and sustainable operations in even the most challenging environments.

Post time: Jun-08-2025