Introduction

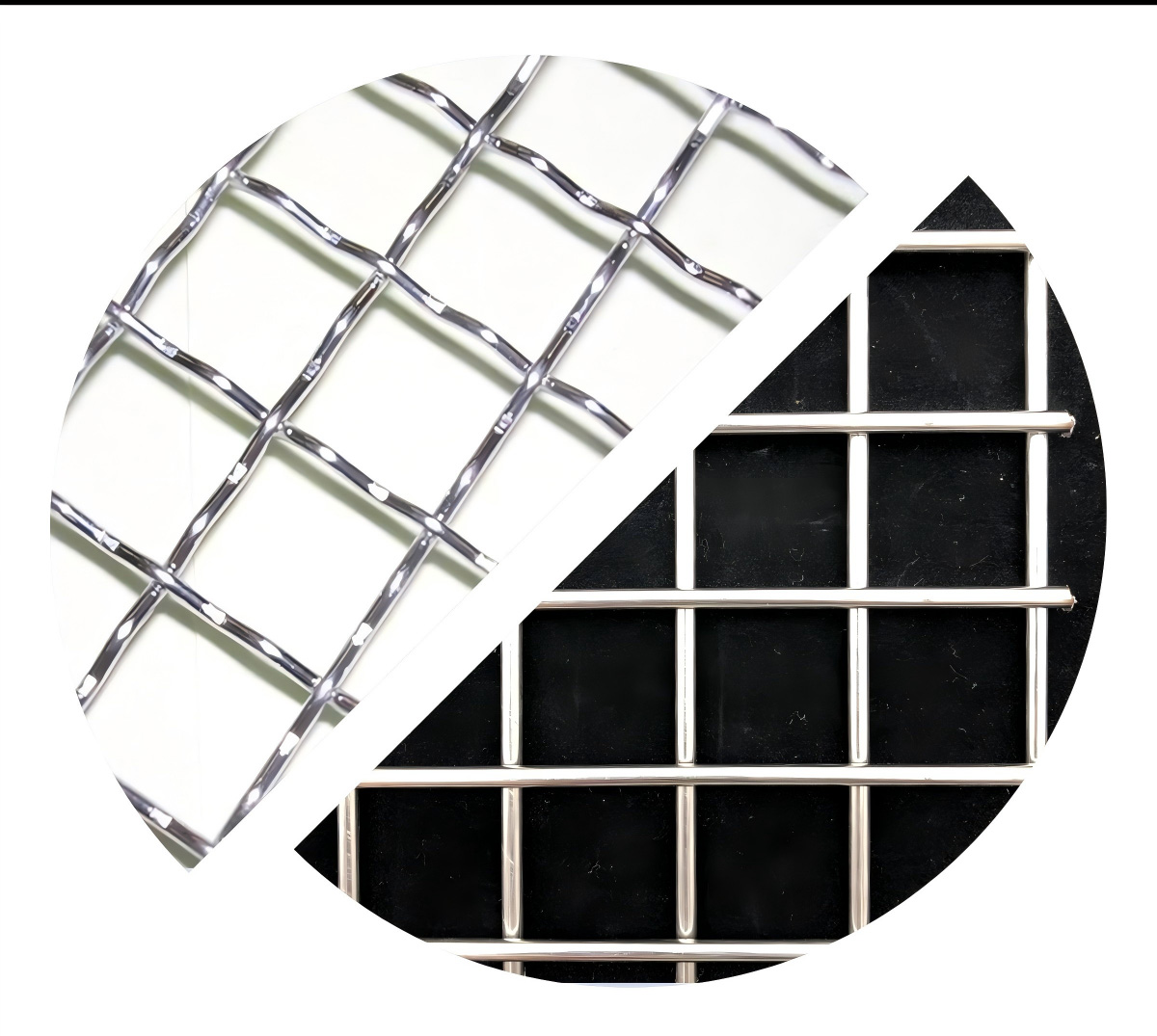

When it comes to selecting the appropriate wire mesh for your project, understanding the differences between woven and welded wire mesh is crucial. Both types have their unique characteristics and applications, and choosing the right one can significantly impact the success of your project. This guide will delve into the distinctions between woven and welded wire mesh, their advantages, disadvantages, and the ideal scenarios for their use.

Woven Wire Mesh: The Versatile Option

Woven wire mesh is created by interlacing wires at right angles to form a uniform grid pattern. This method results in a flexible and durable mesh that can be used in a wide range of applications.

Advantages of Woven Wire Mesh

- Versatility: Woven wire mesh is available in various materials, wire diameters, and opening sizes, making it suitable for numerous applications.

- Strength and Durability: The interwoven structure provides excellent strength and can withstand high tension without deforming.

- Filtering and Screening: Ideal for filtration, sieving, and screening applications due to its consistent and precise opening sizes.

- Customization: Can be customized to meet specific project requirements, including different edge treatments and frame options.

- Cost: Generally more expensive than welded wire mesh due to the complexity of the manufacturing process.

- Potential for Loose Ends: In some cases, the ends of the wires can become loose, which may require additional maintenance.

Disadvantages of Woven Wire Mesh

Welded Wire Mesh: The Economical Solution

Welded wire mesh is produced by welding intersecting wires at their contact points, resulting in a rigid and stable structure.

Advantages of Welded Wire Mesh

- Cost-Effective: Typically less expensive than woven wire mesh, making it a popular choice for large-scale projects.

- Strength and Stability: The welded intersections provide a stable and rigid structure that is ideal for construction and reinforcement applications.

- Ease of Installation: The flat, stable surface of welded wire mesh makes it easier to handle and install.

- Minimal Maintenance: The welded structure is less prone to wire movement, reducing the need for maintenance.

- Limited Flexibility: Not as flexible as woven wire mesh, which can limit its use in applications requiring bending or forming.

- Potential for Rust: The welding process can create points of weakness where rust may form, especially if the mesh is not galvanized or coated.

- Less Uniform Openings: The welding process can sometimes cause slight distortions in the mesh openings, which may not be ideal for precise screening applications.

Disadvantages of Welded Wire Mesh

Choosing the Right Mesh for Your Project

To choose between woven and welded wire mesh, consider the following factors:

- Application Requirements: Determine the primary use of the mesh. For applications requiring flexibility, strength, and precise openings, woven wire mesh is often the better choice. For construction, reinforcement, and applications where cost is a significant factor, welded wire mesh may be more suitable.

- Budget: Evaluate your budget carefully. While welded wire mesh is generally more cost-effective, the long-term benefits of woven wire mesh may justify the higher initial cost in some cases.

- Maintenance and Longevity: Consider the maintenance requirements and the expected lifespan of the mesh. Woven wire mesh may require more maintenance but offers greater longevity, while welded wire mesh is easier to maintain but may have a shorter lifespan.

Conclusion

Both woven and welded wire mesh have their unique advantages and disadvantages, and the best choice will depend on your specific project requirements. By carefully considering the factors outlined in this guide, you can make an informed decision that will ensure the success of your project. For further assistance or to discuss your wire mesh needs, contact Wire Mesh Solutions today.

Post time: Sep-18-2025