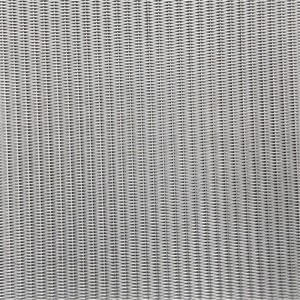

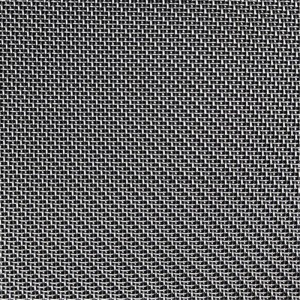

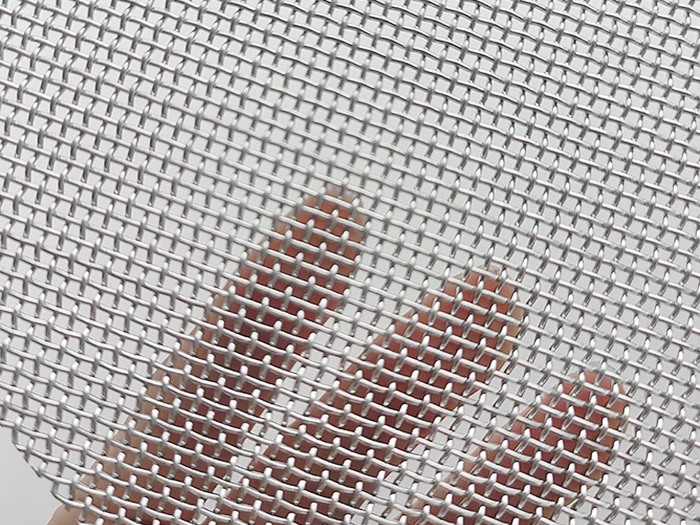

Platinum wire mesh

Platinum Wire Mesh: The Definitive Material for Demanding Applications

In environments where ordinary materials falter—under intense heat, corrosive chemicals, and stringent electrical demands—our Platinum Wire Mesh stands as the definitive solution. This is not merely a metal screen; it is a precision-engineered component crafted from one of the most resilient and versatile precious metals.

Product Attributes

| Mesh Count (Mesh/Inch) | Wire Diameter (mm) | Nominal Aperture (mm) | Open Area (%) | Typical Weight (g/m², for Pure Pt)* | |

| Very Fine Mesh | 200 | 0.04 | 0.087 | ~38% | ~54 |

| 150 | 0.05 | 0.119 | ~50% | ~67 | |

| Fine Mesh | 100 | 0.06 | 0.194 | ~59% | ~81 |

| 80 | 0.09 | 0.228 | ~53% | ~137 | |

| Medium Mesh | 60 | 0.1 | 0.323 | ~59% | ~169 |

| 52 (Common Std.) | 0.11 | 0.378 | ~61% | ~204 | |

| Coarse Mesh | 30 | 0.15 | 0.696 | ~69% | ~397 |

| 20 | 0.2 | 1.07 | ~72% | ~706 |

Ultimate Material Integrity

Fabricated from high-purity platinum (≥99.95%), our mesh offers an unparalleled combination of properties.

Precision Fabrication

This includes tailored Mesh Count (wires per inch), precise Wire Diameter, and controlled Aperture Size.

Inherent Functional Properties

Beyond heat and corrosion resistance, platinum is an excellent conductor of electricity.

Critical Applications Driving Innovation

Chemical & Process Catalysis: It serves as the premier catalyst or catalyst support gauze in ammonia oxidation for nitric acid production and other high-temperature catalytic reactions.

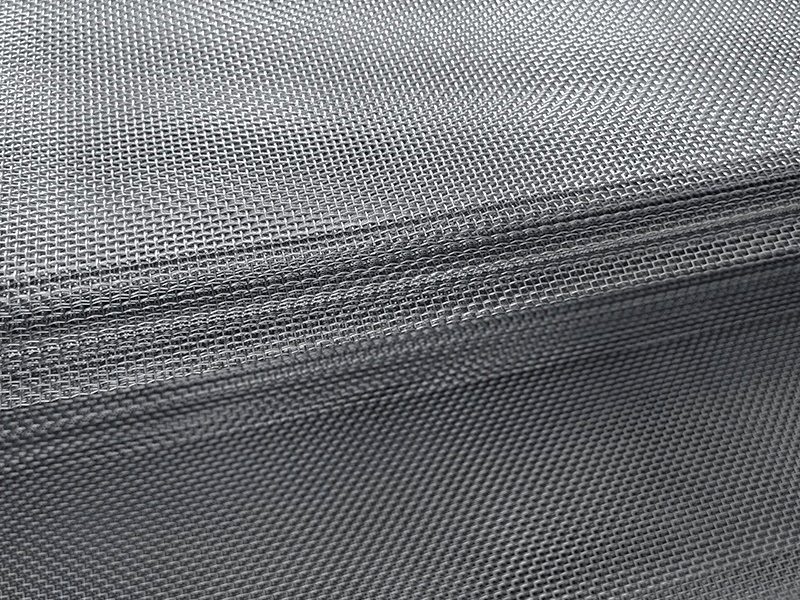

Advanced Filtration Systems: Used to filter hot, corrosive gases and molten materials in the glass industry, chemical processing, and emission control systems.

Energy Technology: A key component in Hydrogen Fuel Cells (PEMFCs) and electrolyzers, functioning as a durable current collector or catalyst substrate that withstands the corrosive fuel cell environment.

Sensors & Electronics: The foundational material for Micro-Hotplate (MHP) structures in high-precision MEMS gas sensors and as reliable heating elements or laboratory electrodes where precision and purity are paramount.

Research & Development: An essential tool in laboratory settings for sample handling, high-temperature experiments, and prototype development in fields from aerospace to pharmaceuticals.

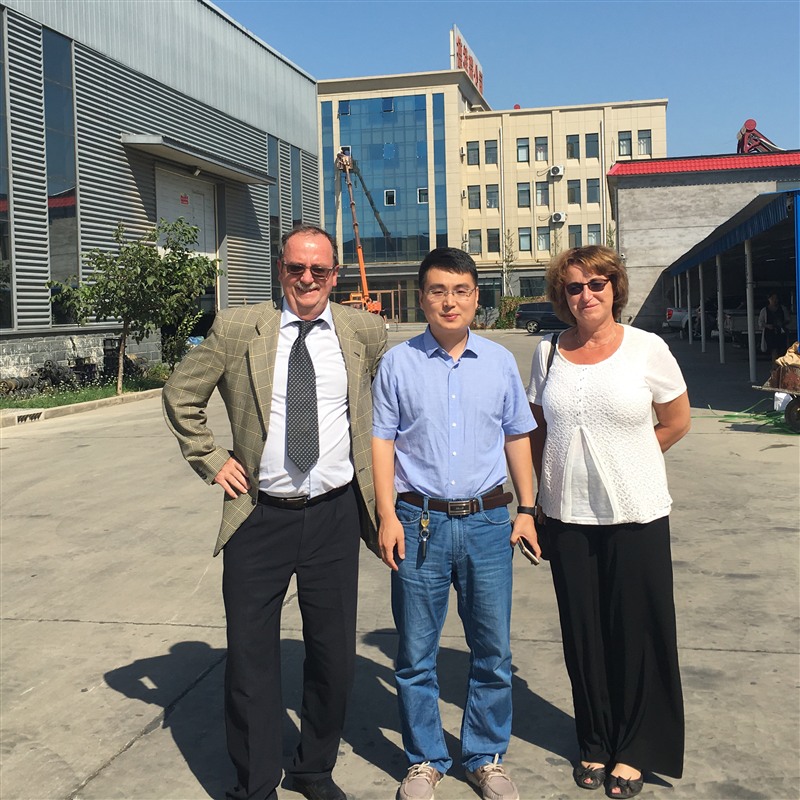

30+years production experience

DXR Wire Mesh is a manufacturing & trading combo of wire mesh and wire cloth in the China.With a track record of over 30 years of business and a technical sales staff with over 30 years of combined experience.

Our Products

DXR's main products are stainless steel wire mesh, filter wire mesh, titanium wire mesh,copper wire mesh, plain steel wire mesh and all kinds of mesh further-processingproducts. Total 6 series, about thousand types of products, widely applied forpetrochemical, aeronautics and astronautics, food, pharmacy, environmentalprotection, new energy, automotive and electronic industry.

In 1988,DeXiangRui Wire Cloth Co, Ltd. was foundedannual value of production is about 30 million US dollars.of which 90% of products delivered to more than 50 countries and regions. DXR brand as a famous brand inHebei Province has been registered in 7 countries aroundthe world for trademark protection.

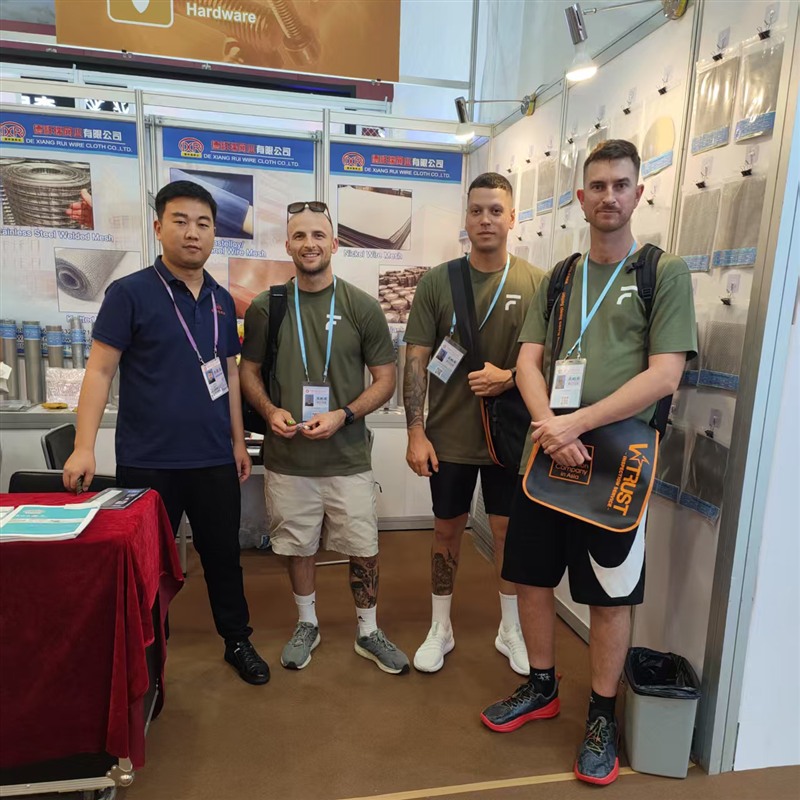

Customers and Exhibitions

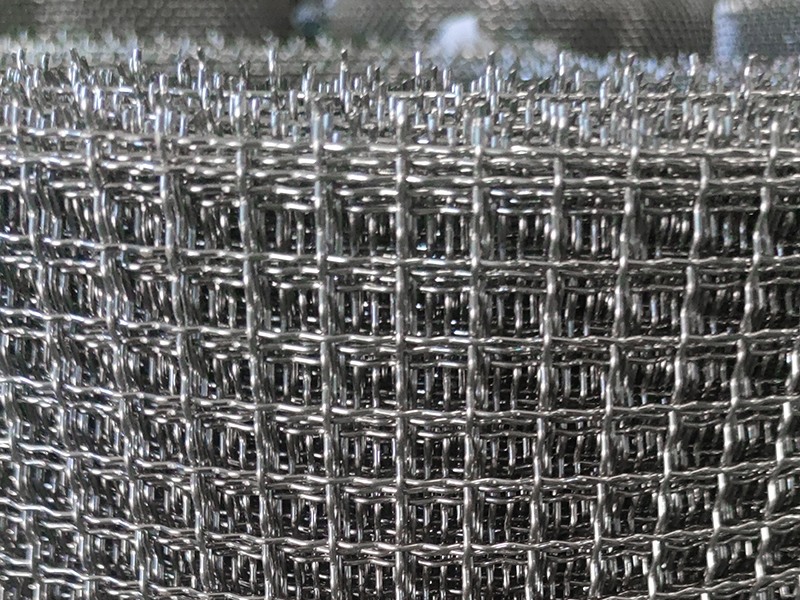

Inside The Factory

Workshop

Production Machine

FAQ

Q1: Is it all right to make customer's own brand name?

A: Yes, we offer OEM service.

Q2: Are you a manufactuer or trading company?

A: We are a professional manufacturer since 1988.

Q3: Can you do the design for us?

A: Yes,Both design and customization are available

Q4: How can I get a sample to check your quality?

A: Please send us an email to sales88@china-wiremesh.net or contact us through this website. We will arrange samples via DHL, FedEx, UPS etc.

Q5: Is the sample free,and How long can I expect to get the sample?

A: Although we support free sample, you need pay the freight.It depends on your address how long it will take to receive it. We can do all the sample in 2 days

Q6: Packaging & Shipping:

A: "Water-proof paper,plastic film, wooden cases or pallets outside.

By sea, train, sea and air. "

Q7: What about the lead time for mass production?

A: Common specifications within 30 days

Q8: Where is your loading port?

A: Tianjin, Qingdao

Q9: How long is the delivery period of the product?

A: 2-30 days

Q10: What quality certifications do you have?

A: CE, ISO 9001:2015, SGS