Umicore Electroplating muGermany inoshandisa tembiricha yepamusoro ye electrolytic anodes.Mukuita uku, platinamu inoiswa pahwaro zvinhu zvakaita setitanium, niobium, tantalum, molybdenum, tungsten, simbi isina tsvina uye nickel alloys mubhavhu remunyu rakanyungudutswa pa550 ° C pasi peargon.

Mufananidzo 2: Kupisa kwakanyanya kwe electroplated platinum/titanium anode inochengetedza chimiro chayo kwenguva yakareba.

Mufananidzo 3: Yakawedzerwa mesh Pt/Ti anode.Yakawedzerwa simbi mesh inopa yakakwana electrolyte yekufambisa.Nharaunda pakati peanode uye cathode components inogona kuderedzwa uye ikozvino density inowedzera.Mhedzisiro: mhando iri nani munguva shoma.

Mufananidzo 4: Hupamhi hwemesh pane yakawedzerwa simbi mesh anode inogona kugadziriswa.Iyo mesh inopa yakawedzera electrolyte kutenderera uye nani gasi kubviswa.

Kutungamira kunotariswa zvakanyanya pasi rese.MuUS, zviremera zvehutano nenzvimbo dzebasa vari kuomerera kune yambiro yavo.Kunyangwe makore ehunyanzvi hwemakambani e electroplating mukubata nezvinhu zvine njodzi, simbi inoramba ichionekwa zvakanyanya uye zvakanyanya.

Semuenzaniso, chero munhu anoshandisa lead anode muUnited States anofanira kunyoresa neEPA's federal Toxic Chemical Release Register.Kana kambani ye electroplating ichiita chete nezve 29 kg yemutobvu pagore, kunyoresa kuchiri kudikanwa.

Naizvozvo, zvinodikanwa kutsvaga imwe nzira muUSA.Haisi chete iyo inotungamira inode yakaoma chromium plating chirimwa inoita seyakachipa pakutanga pakuona, kune zvakare akawanda akashata:

Dimensionally stable anodes inzira inofadza kune yakaoma chromium plating (ona Fig. 2) ine platinamu pamusoro petitanium kana niobium se substrate.

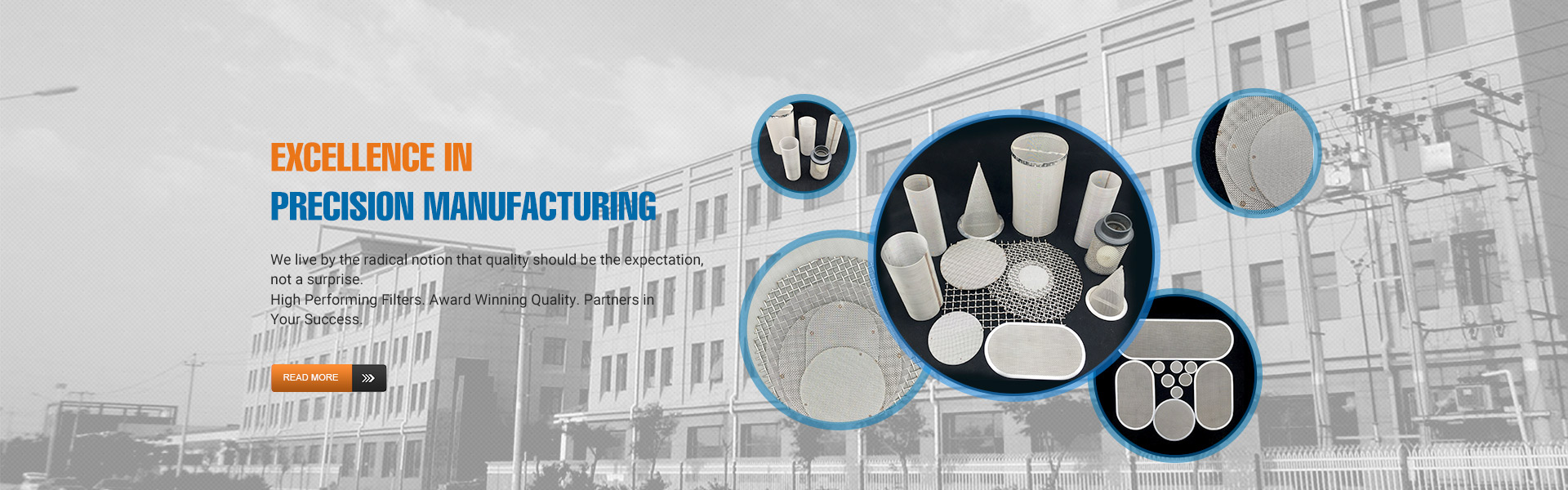

Platinamu yakavharwa anode inopa akawanda mabhenefiti pane yakaoma chromium plating.Izvi zvinosanganisira zvinotevera zvinobatsira:

Kuti uwane mhedzisiro yakanaka, shandura iyo anode kune dhizaini yechikamu chinofanira kuputirwa.Izvi zvinoita kuti zvikwanisike kuwana anode ane zvimiro zvakatsiga (mandiro, masilinda, T-akaumbwa uye U-akaumbwa), nepo lead anode ari kunyanya akajairwa mashizha kana tsvimbo.

Pt/Ti uye Pt/Nb anode haana nzvimbo dzakavharika, asi akawedzera simbi masheets ane siyana mesh size.Izvi zvinotungamirira pakugoverwa kwakanaka kwesimba, minda yemagetsi inogona kushanda mukati uye kumativi ose emambure (ona Fig. 3).

Naizvozvo, diki chinhambwe pakati peanodeuye cathode, iyo yakakwirira ye flux density yejasi.Matanho anogona kuiswa nekukurumidza: goho rinowedzerwa.Kushandiswa kwemagridhi ane nzvimbo yakakura inoshanda yepamusoro inogona kuvandudza zvakanyanya mamiriro ekuparadzanisa.

Dimensional kugadzikana kunogona kuwanikwa nekubatanidza platinum uye titanium.Masimbi ese ari maviri anopa akakwana paramita kune yakaoma chrome plating.Iyo resistivity yeplatinamu yakaderera kwazvo, chete 0.107 Ohm × mm2/m.Kukosha kwemutobvu kunoda kupeta zvakapetwa kaviri zvemutobvu (0.208 ohm×mm2/m).Titanium ine yakanakisa corrosion resistance, zvisinei kugona uku kunodzikiswa pamberi pe halides.Semuenzaniso, kuparara kwemagetsi etitanium mukloride-ine electrolytes inotangira pa10 kusvika ku15 V, zvichienderana nepH.Izvi zvakakwirira zvakanyanya kupfuura izvo zve niobium (35 kusvika 50 V) uye tantalum (70 kusvika 100 V).

Titanium ine zvayakaipira maererano nekudzivirirwa kwecorrosion mumaasidhi akasimba akadai sesulfuric, nitric, hydrofluoric, oxalic uye methanesulfonic acids.Zvisinei,titaniumichiri sarudzo yakanaka nekuda kwekugona kwayo uye mutengo.

Kuiswa kwechidimbu cheplatinamu pane titanium substrate kunonyatsoitwa electrochemically nepamusoro tembiricha electrolysis (HTE) mumunyu wakanyunguduka.Iyo yakaomesesa yeHTE process inovimbisa kuvharika chaiko: mubhavhu re550 ° C rakanyungudutswa rakagadzirwa kubva musanganiswa we potassium uye sodium cyanides ine inenge 1% kusvika 3% yeplatinum, simbi yakakosha inoiswa electrochemically patitanium.Iyo substrate yakavharwa muvharo yakavharwa ne argon, uye bhati yemunyu iri mune kaviri crucible.Currents kubva pa1 kusvika pa5 A/dm2 inopa insulation rate ye10 kusvika 50 microns paawa ine coating tension ye 0.5 kusvika 2 V.

Platinized anodes uchishandisa maitiro eHTE akanyanya kudarika anode akavharwa neaqueous electrolyte.Kuchena kweplatinum yekuputira kubva munyu yakanyungudutswa inosvika 99.9%, iyo yakanyanya kukwirira kupfuura iyo yeplatinamu yakaiswa kubva kune aqueous mhinduro.Yakanyanya kunatsiridza ductility, adhesion uye corrosion resistance nekushomeka kwemukati tension.

Kana uchifunga nezve optimization yeanode dhizaini, inonyanya kukosha ndeye optimization yerutsigiro chimiro uye anode magetsi ekupa.Mhinduro yakanakisisa ndeyokupisa uye mhepo yetitanium sheet coating pamhangura yemhangura.Mhangura ndiyo yakanaka conductor ine resistivity inosvika 9% chete yePb/Sn alloys.Iyo CuTi magetsi inogonesa kurasikirwa kwesimba kushoma chete pamwe chete neanode, saka iyo layer yekuparadzira pagungano recathode yakafanana.

Imwe mhedzisiro yakanaka ndeyekuti kupisa kushoma kunogadzirwa.Zvinodiwa zvekutonhora zvakaderedzwa uye kupfeka kweplatinamu pane anode kunoderedzwa.Anti-corrosion titanium coating inodzivirira copper core.Kana uchidzokorodza simbi yakawedzerwa, chenesa uye gadzirira chete furemu uye/kana magetsi.Vanogona kushandiswa zvakare kakawanda.

Nekutevedzera dhizaini iyi, unogona kushandisa Pt/Ti kana Pt/Nb modhi kugadzira “akanaka anode” kune yakaoma chromium plating.Dimensionally yakagadzikana modhi inodhura zvakanyanya padanho rekudyara pane lead anode.Nekudaro, kana uchifunga nezve mutengo mune zvakadzama, platinamu-yakaputirwa titanium modhi inogona kuve inonakidza imwe nzira kune yakaoma chrome plating.

Izvi zvinokonzerwa nekuongorora kwakazara uye kwakakwana kwemutengo wakazara weyakajairika lead uye platinum anode.

Eight lead alloy anodes (1700 mm kureba uye 40 mm mudhayamita) yakagadzirwa nePbSn7 yakaenzaniswa neyakakwana saizi Pt/Ti anode yechromium plating yecylindrical parts.Kugadzira sere lead anode kunodhura madhora zviuru zana nemazana mana (1,471 US madhora), uko pakutanga kutarisa kunoita sekuchipa.Mari inodiwa kuvandudza inodiwa Pt / Ti anode yakakwira zvakanyanya.Mutengo wekutanga wekutenga unotenderedza 7,000 euros.Kupera kwePlatinum kunodhura zvakanyanya.Chete masimbi anokosha anosvika makumi mana neshanu muzana emari iyi.A 2.5 µm gobvu platinum coating inoda 11.3 g yesimbi yakakosha kune imwe neimwe yemaanode masere.Pamutengo we35 euros pagiramu, izvi zvinoenderana ne3160 euros.

Nepo lead anode ingaite senge yakanakisa sarudzo, izvi zvinogona kukurumidza kuchinja kana wanyatsoongorora.Mushure memakore matatu chete, mutengo wakakwana weanode inotungamira wakakwira zvakanyanya kupfuura Pt/Ti modhi.Mumuenzaniso wekuverengera wekuverenga, fungidzira akajairika application flux density ye40 A/dm2.Nekuda kweizvozvo, kuyerera kwesimba pane yakapihwa anode pamusoro pe168 dm2 yaive 6720 amperes pa6700 maawa ekushanda kwemakore matatu.Izvi zvinoenderana nemazuva ekushanda angangoita 220 kubva pamaawa gumi ekushanda pagore.Sezvo iyo platinamu inopinda mumhinduro, ukobvu hweplatinamu hunoderera zvishoma nezvishoma.Mumuenzaniso, izvi zvinoonekwa semagiramu maviri pamiriyoni amp-awa.

Pane zvikonzero zvakawanda zvemutengo mukana wePt/Ti pamusoro pe lead anode.Pamusoro pezvo, kushandiswa kwemagetsi kwakaderedzwa (mutengo 0.14 EUR/kWh kubvisa 14,800 kWh/gore) kunodhura 2,000 EUR pagore.Pamusoro pezvo, hapasisina kudiwa kwemutengo wepagore weanosvika mazana mashanu emaeuro ekurasa lead chromate sludge, pamwe ne1000 euros yekuchengetedza uye kugadzira downtime - inochengetedza maverengero.

Mutengo wese weanode ye lead mumakore matatu yaive €14,400 ($15,130).Mutengo wePt/Ti anodes i12,020 euros, kusanganisira kudzoreredza.Kunyangwe pasina kutarisisa mutengo wekugadzirisa uye kuderera kwekugadzira (1000 euros pazuva pagore), iyo yekutyora-nyangwe poindi inosvika mushure memakore matatu.Kubva panguva ino zvichienda mberi, musiyano uri pakati pavo unowedzera zvakanyanya mukufarira Pt / Ti anode.

Maindasitiri mazhinji anotora mukana weakasiyana mabhenefiti epamusoro tembiricha yeplatinamu yakavharwa electrolytic anodes.Kuvhenekera, semiconductor uye vanogadzira bhodhi redunhu, mota, hydraulics, migodhi, maworkwork emvura uye madziva ekushambira anovimba neaya matekinoroji ekuputira.Mamwe maapplication achagadziridzwa mune ramangwana, sezvo mutengo wakasimba uye kufunga kwezvakatipoteredza kuri kunetseka kwenguva refu.Nekuda kweizvozvo, mutungamiri anogona kutarisana nekuwedzera kuongororwa.

Chinyorwa chekutanga chakabudiswa muchiGerman muAnnual Surface Technology (Vol. 71, 2015) rakapepetwa naProf. Timo Sörgel vanobva kuAalen University of Applied Sciences, Germany.Rubatsiro rwaEugen G. Leuze Verlag, Bad Saulgau/Germany.

Muzhinji simbi yekupedzisa mashandiro, masking inoshandiswa, uko chete dzimwe nzvimbo dzepamusoro pechikamu dzinofanirwa kugadziriswa.Pane kudaro, masking inogona kushandiswa panzvimbo apo kurapwa kusingadiwi kana kunofanira kudzivirirwa.Ichi chinyorwa chinobata akawanda maficha esimbi yekupedzisa masking, kusanganisira mashandisirwo, matekiniki, uye akasiyana marudzi emasiki anoshandiswa.

Nguva yekutumira: May-25-2023