Stainless Steel Perforated Tubes

Perforated Tubes – Purify Liquids and Sieve Materials

Perforated tubes are made of aluminum, stainless steel, carbon steel and alloy sheet. According to opening diameter, we design the width of plate and punch holes customized by you.

Perforated tube specifications

| Specification Category | Details / Range |

|---|---|

| Materials | Aluminum Plate, Stainless Steel Plate, Galvanized Steel Plate, Alloy Plate, Iron Plate, Carbon Steel Plate, Copper Plate |

| Thickness | 0.4 – 15 mm |

| Tube Length | 10 – 6000 mm (Custom sizes available) |

| Tube Outside Diameter (O.D.) | 6 – 200 mm |

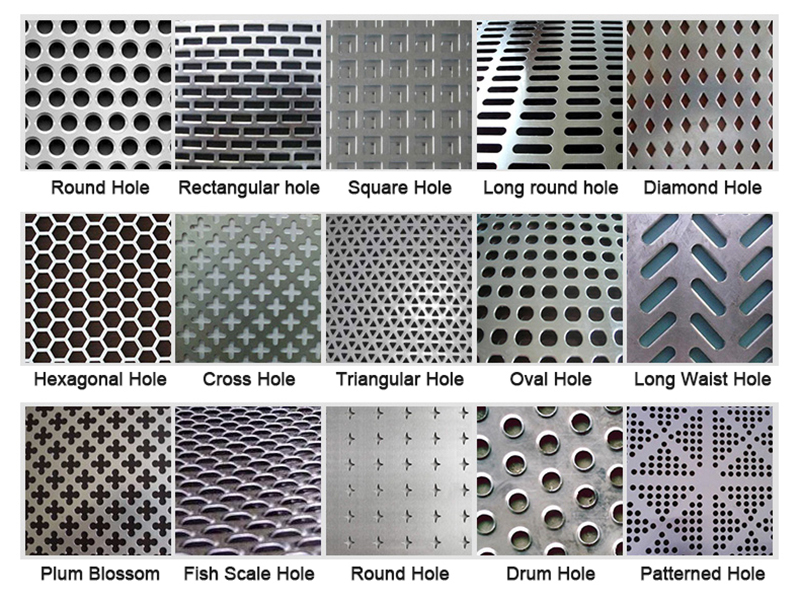

| Wall Hole Pattern | Round, Rectangular, Square, Hexagonal, Oval, Plum Blossom, etc. |

| Hole Diameter | 3 – 10 mm |

| Open Area | 23% – 69% |

| Filter Precision | 2 – 2000 μm |

With durable materials and various models

High Quality

The wire mesh can be woven in different patterns and mesh sizes to meet the desired filtration or separation needs.

- • Uniform welds and good pressure resistance.

- • Accurate roundness and straightness.

- • Smooth and flat surface.

- • High filter precision.

- • Also can cut the noise and ventilate.

- • Resist acid, alkali, low and high temperature, so has a long service life.

Applications of Perforated Mesh Tubes

Perforated mesh tubes are versatile components with a wide range of industrial and commercial applications. Their functionality spans filtration, separation, structural support, and aesthetics.

1. Filtration of Liquids and Gases

-

Designed for the efficient filtration of various fluids, including water, oil, fuel, and chemicals.

-

Used in air intake and exhaust systems to remove dust, particulate matter, and other contaminants, ensuring cleaner operational outputs.

2. Material Screening and Purification

-

Essential for sieving, grading, and separating different materials across multiple industries.

-

Key Sectors:

-

Food & Beverage: Sorting grains, powders, and ingredients.

-

Pharmaceutical: Screening active ingredients and excipients to ensure product purity and consistency.

-

Chemical: Separating catalysts, filtering slurries, and purifying chemical products.

-

Environmental Protection: Used in wastewater treatment and waste separation processes.

-

3. Structural Framework for Filter Elements

-

Serves as a robust, customizable core and support structure for various filter cartridges and elements.

-

Provides mechanical strength and stability, allowing filter media to withstand high pressure and flow rates without collapsing.

4. Noise Attenuation (Acoustic Damping)

-

Functions as an effective noise reduction solution.

-

The precise perforations help disrupt and absorb sound waves, making them suitable for machinery enclosures, industrial silencers, and engine components to lower operational noise levels.

5. Ventilation and Aeration Systems

-

Widely implemented in agricultural storage, particularly in granaries and silos.

-

Facilitates optimal air circulation, preventing moisture buildup, mold growth, and spoilage of stored grains and other bulk materials.

6. Architectural and Design Elements

-

Lighting Covers: Used as stylish and functional shades for indoor and outdoor lighting fixtures, creating appealing light patterns and ensuring safety.

-

Ceiling and Wall Decor: A popular choice for modern interior design, these tubes are used to create decorative ceilings, room dividers, and facade claddings, offering a blend of aesthetics and functionality.

30+ years production experience

In 1988,DeXiangRui Wire Cloth Co, Ltd. was foundedannual value of production is about 30 million US dollars.of which 90% of products delivered to more than 50 countries and regions. DXR brand as a famous brand inHebei Province has been registered in 7 countries aroundthe world for trademark protection.

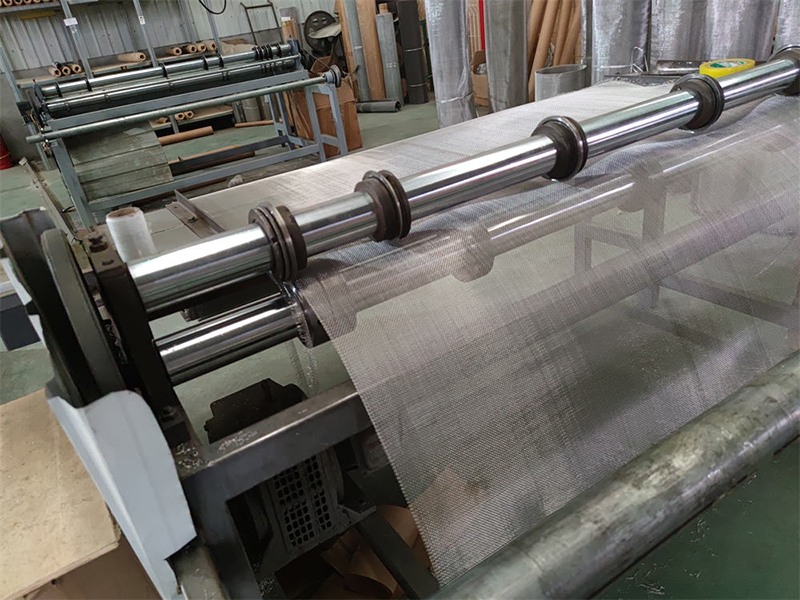

▶ Production Machine

▶ Inside The Factory

▶ Customers and Exhibitions