titanium anode

Titanium Anode

Titanium anode (also known as titanium-based metal oxide coated anode, DSA, Dimensionally Stable Anode) is a high-performance electrode material widely used in the field of electrochemistry. It has excellent corrosion resistance, high catalytic activity and long life.

Common coatings:

Ruthenium (RuO₂): suitable for chlor-alkali industry, resistant to Cl⁻ corrosion.

Iridium (IrO₂): strong acid resistance, suitable for wastewater treatment.

Platinum coating: used for high-purity titanium electrolysis, resistant to high temperature (600℃).

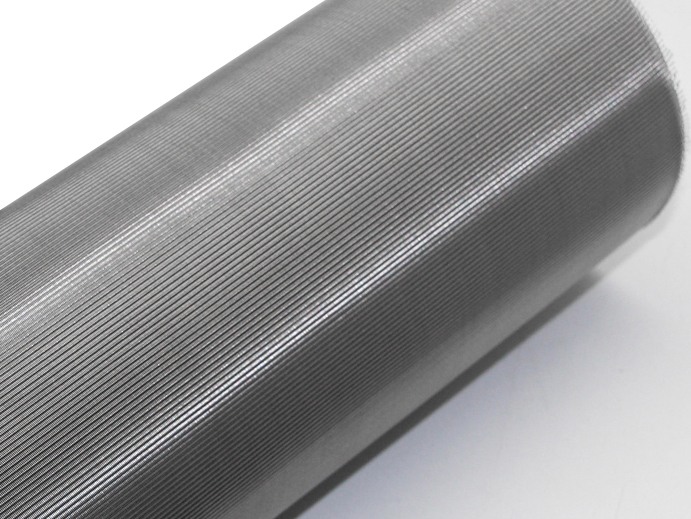

Structural form: plate, tube, mesh, wire, etc., can be customized according to needs.

Regular cleaning: rinse with deionized water after shutdown to avoid scale deposition.

Avoid mechanical damage: damage to the platinum layer will cause rapid corrosion of the titanium substrate.

Electrolytic activation: reverse current treatment every 3000 hours to strip off the passivation layer.

Composite coatings: such as platinum-iridium gradient coatings, further reducing the oxygen evolution overpotential (the laboratory has reached 1.25V).

Intelligent monitoring: integrated sensors monitor coating loss in real time.

Environmental protection and new energy applications: such as solid-state batteries and efficient hydrogen production.

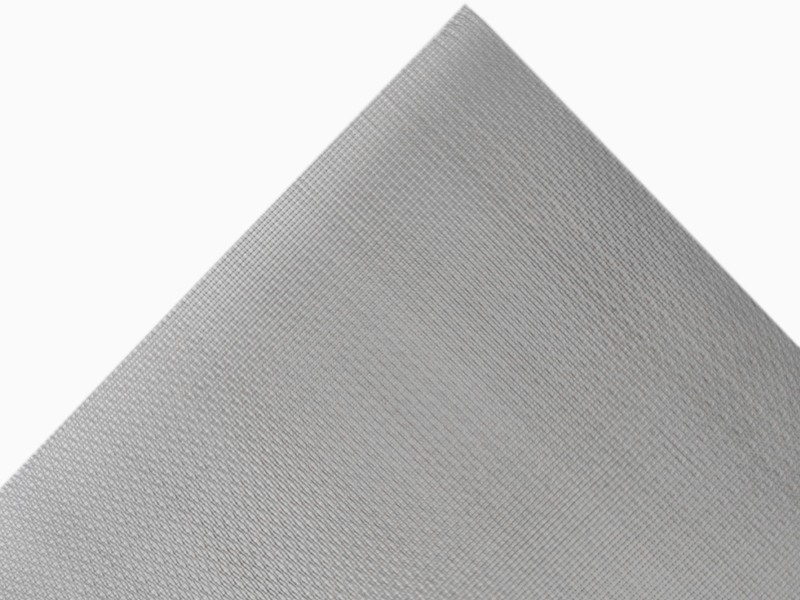

Product Attributes

| Mesh (Wires/ in.) | Wire diameter (in.) | Width of opening (in.) | Open area (%) |

| 4 × 4 | 0.032 | 0.218 | 76 |

| 4 × 4 | 0.035 | 0.215 | 74 |

| 6 × 6 | 0.032 | 0.135 | 65.6 |

| 7 × 7 | 0.025 | 0.118 | 68.2 |

| 8 × 8 | 0.032 | 0.093 | 55.4 |

| 9 × 9 | 0.032 | 0.079 | 50.6 |

| 10 × 10 | 0.035 | 0.065 | 42.3 |

| 10 × 10 | 0.03 | 0.07 | 49 |

| 10 × 10 | 0.025 | 0.075 | 56.3 |

| 12 × 12 | 0.011 | 0.0723 | 75.3 |

| 14 × 14 | 0.016 | 0.055 | 60.2 |

| 16 × 16 | 0.006 | 0.0565 | 81.7 |

| 18 × 18 | 0.01 | 0.046 | 67.4 |

| 18 × 18 | 0.011 | 0.0445 | 64.4 |

| 18 × 18 | 0.016 | 0.04 | 50.8 |

| 20 × 20 | 0.003 | 0.047 | 88.4 |

| 20 × 20 | 0.02 | 0.03 | 36 |

| 24 × 24 | 0.01 | 0.032 | 57.9 |

| 24 × 24 | 0.0118 | 0.0299 | 51.4 |

| 26 × 26 | 0.01 | 0.029 | 54.9 |

| 30 × 30 | 0.01 | 0.0233 | 49 |

| 32 × 32 | 0.01 | 0.021 | 46.5 |

| 35 × 35 | 0.008 | 0.0206 | 51.8 |

| 40 × 40 | 0.005 | 0.02 | 64 |

| 40 × 40 | 0.01 | 0.015 | 36 |

| 50 × 50 | 0.009 | 0.011 | 30.3 |

| 60 × 60 | 0.009 | 0.0077 | 21.3 |

| 90 × 90 | 0.004 | 0.0071 | 41 |

| 100 × 100 | 0.002 | 0.008 | 64 |

| 120 × 120 | 0.004 | 0.0043 | 27 |

| 150 × 150 | 0.0027 | 0.004 | 35.5 |

Core characteristics of titanium anode

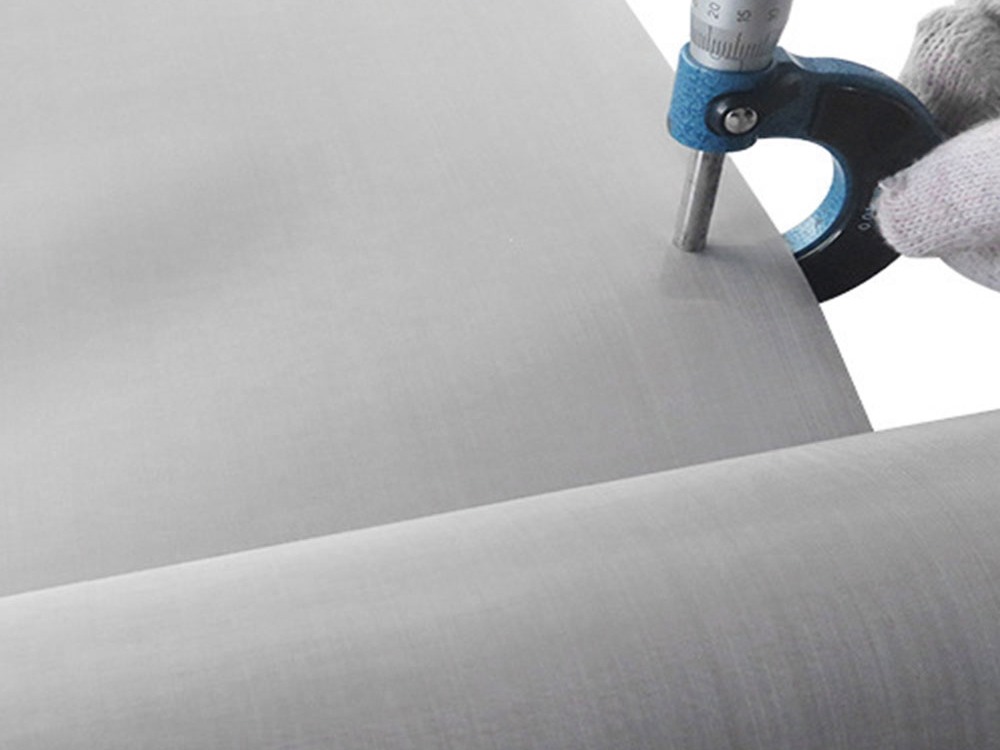

Dimensional stability

The electrode spacing remains unchanged during the electrolysis process, ensuring stable cell voltage.

Strong corrosion resistance

Suitable for strong acid, strong alkali and Cl⁻-containing media, with corrosion resistance far exceeding that of graphite and lead anodes.

Low operating voltage

Low overpotential for oxygen/chlorine evolution, saving 10%-20% energy.

Long life

In the chlor-alkali industry, the life span can reach 6 years, while that of graphite anode is only 8 months.

High current density

Supports 17A/dm² (graphite anode is only 8A/dm²), improving production efficiency.

Main application areas

- Electrolysis of brine to produce chlorine and caustic soda, titanium anode can reduce cell voltage and improve chlorine purity.

- Replace graphite anode to avoid electrolyte contamination.

- Electrocatalytic oxidation: Degrade organic matter in printing and dyeing, pharmaceutical, and coking wastewater, with a COD removal rate of up to 90%.

- Sodium hypochlorite generator: Electrolyze brine to generate disinfectant, used for hospital sewage and swimming pool water treatment.

- Radioactive wastewater treatment: Electrolytic recovery of radioactive metals such as uranium and plutonium.

- Used for nickel plating, chromium plating, gold plating, etc. to improve the uniformity of the plating layer and reduce plating solution pollution.

- The oxygen evolution overpotential is 0.5V lower than that of the lead anode, which saves energy significantly.

- Extract metals such as copper, zinc, and nickel, replace the lead anode, and avoid cathode contamination.

- Suitable for high current density (such as 8000A/m²) and narrow inter-electrode spacing (5mm) conditions.

- Hydrogen production by electrolysis of water: Reduce the oxygen evolution overpotential and improve energy efficiency.

- Solid-state battery: used for titanium-based plate manufacturing.

- Cathodic protection: anti-corrosion of marine steel structures, with a service life of more than 10 years.

- Electrochemical synthesis: such as preparation of organic compounds and pharmaceutical intermediates.

30+years production experience

DXR Wire Mesh is a manufacturing & trading combo of wire mesh and wire cloth in the China.With a track record of over 30 years of business and a technical sales staff with over 30 years of combined experience.

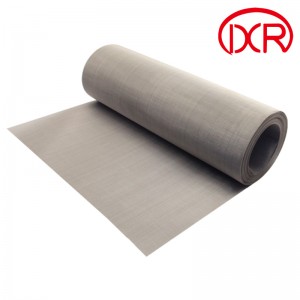

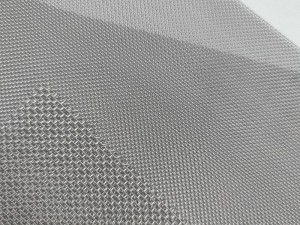

Our Products

DXR's main products are stainless steel wire mesh, filter wire mesh, titanium wire mesh,copper wire mesh, plain steel wire mesh and all kinds of mesh further-processingproducts. Total 6 series, about thousand types of products, widely applied forpetrochemical, aeronautics and astronautics, food, pharmacy, environmentalprotection, new energy, automotive and electronic industry.

In 1988,DeXiangRui Wire Cloth Co, Ltd. was foundedannual value of production is about 30 million US dollars.of which 90% of products delivered to more than 50 countries and regions. DXR brand as a famous brand inHebei Province has been registered in 7 countries aroundthe world for trademark protection.

Customers and Exhibitions

Inside The Factory

Workshop

Production Machine

FAQ

Q1: Is it all right to make customer's own brand name?

A: Yes, we offer OEM service.

Q2: Are you a manufactuer or trading company?

A: We are a professional manufacturer since 1988.

Q3: Can you do the design for us?

A: Yes,Both design and customization are available

Q4: How can I get a sample to check your quality?

A: Please send us an email to sales88@china-wiremesh.net or contact us through this website. We will arrange samples via DHL, FedEx, UPS etc.

Q5: Is the sample free,and How long can I expect to get the sample?

A: Although we support free sample, you need pay the freight.It depends on your address how long it will take to receive it. We can do all the sample in 2 days

Q6: Packaging & Shipping:

A: "Water-proof paper,plastic film, wooden cases or pallets outside.

By sea, train, sea and air. "

Q7: What about the lead time for mass production?

A: Common specifications within 30 days

Q8: Where is your loading port?

A: Tianjin, Qingdao

Q9: How long is the delivery period of the product?

A: 2-30 days

Q10: What quality certifications do you have?

A: CE, ISO 9001:2015, SGS