High-Quality Copper Knitted Mesh

Product Description

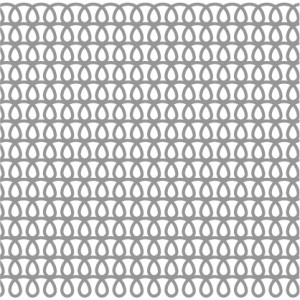

The unique knitted design provides enhanced structural integrity while maintaining permeability, making it suitable for a wide range of industrial processes such as filtration, separation, shielding, and heat dissipation. Each mesh is produced using advanced knitting technology that ensures uniform density and precise opening sizes, guaranteeing consistent performance even in demanding environments.

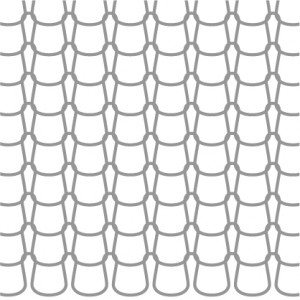

Fine Mesh

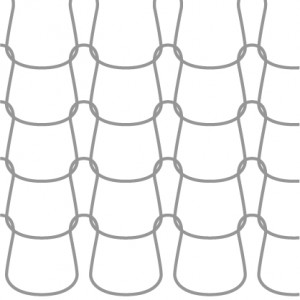

Medium-Fine Mesh

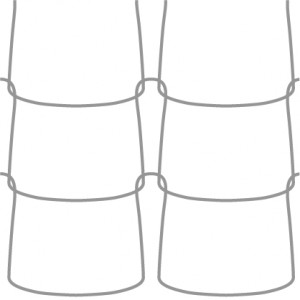

Standard Mesh

Super-Coarse Mesh

Superior Material Purity

Made from 99.9% high-purity copper, ensuring optimal conductivity and corrosion resistance for long-term industrial use.

Enhanced Structural Flexibility

Knitted construction provides better elasticity and load-bearing capacity compared to woven meshes, adapting to complex installations.

Cost-Effective Durability

Long service life reduces replacement frequency, lowering total operational costs for end-users.

Product Attributes

| Material | stainless steel 304,304L,316,316L,310S,321, brass, copper, monel, nickel,titanium |

| Wire diameter | 0.1-0.55mm flat wire or round wire. Usual 0.20mm-0.25mm. |

| Hole Sizes | 4mm×3mm 5mm×6mm 2mmx4mm, 4mmx5mm etc... |

| Hole shape | irregular |

| Width | 40mm, 80mm, 100mm, 150mm, 200mm, 300mm, 400mm, 500 mm, 600mm, etc. |

| Length | 30-200m, customized size is available. |

| Thickness | 0.12mm-2.5mm, customized size is available |

| Craft | through layered, spiral wound or compressed, produces a tortuous path for highly effective particle capture. |

| Surface | flat-type and corrugated type |

| Customized | Acceptable |

Product Applications

Copper knitted wire mesh is widely used in the industrial field due to its excellent corrosion resistance, thermal conductivity and plasticity.

1. Copper knitted wire mesh separation and demisting

Wire mesh demister: used to separate liquid droplets (fog) in gas in towers (such as distillation towers, absorption towers, evaporators), with a filtration accuracy of 3~5μm and an efficiency of 98%~99.8%.

Application scenarios:

Petroleum refining (such as catalytic cracking units, natural gas desulfurization towers).

Chemical production (purification of acidic gases such as sulfuric acid, hydrochloric acid, acetic acid).

Pharmaceutical industry (solvent recovery, waste gas treatment).

2. Environmental protection engineering

Desulfurization and demisting: remove droplets carried by SO₂ gas in flue gas desulfurization (FGD) systems.

Wastewater treatment: used as filler in aeration tanks to increase oxygen transfer efficiency.

3. Mechanical and automotive industry

Air compressor/refrigeration system: filter oil-water mixture in compressed air.

Noise reduction and shock absorption: as a porous sound-absorbing material, reduce equipment noise.

4. Electronics and medical fields

Electromagnetic shielding: using the conductivity of copper for electromagnetic interference (EMI) protection of precision instruments.

High-precision filtration: such as medical air purification equipment, ultra-pure gas filtration in the semiconductor industry.

5. Other special uses

High temperature environment: copper is resistant to high temperatures (melting point 1083℃), suitable for hot air furnaces and boiler exhaust gas treatment.

Laboratory equipment: customized micro-filters are used for Copper knitted wire mesh contact in chemical reactors.

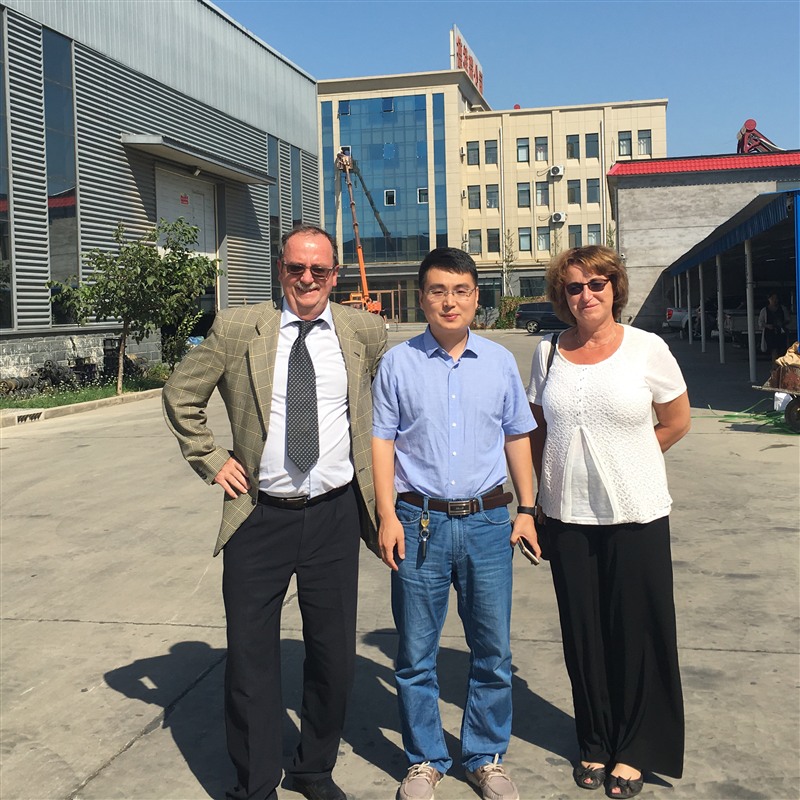

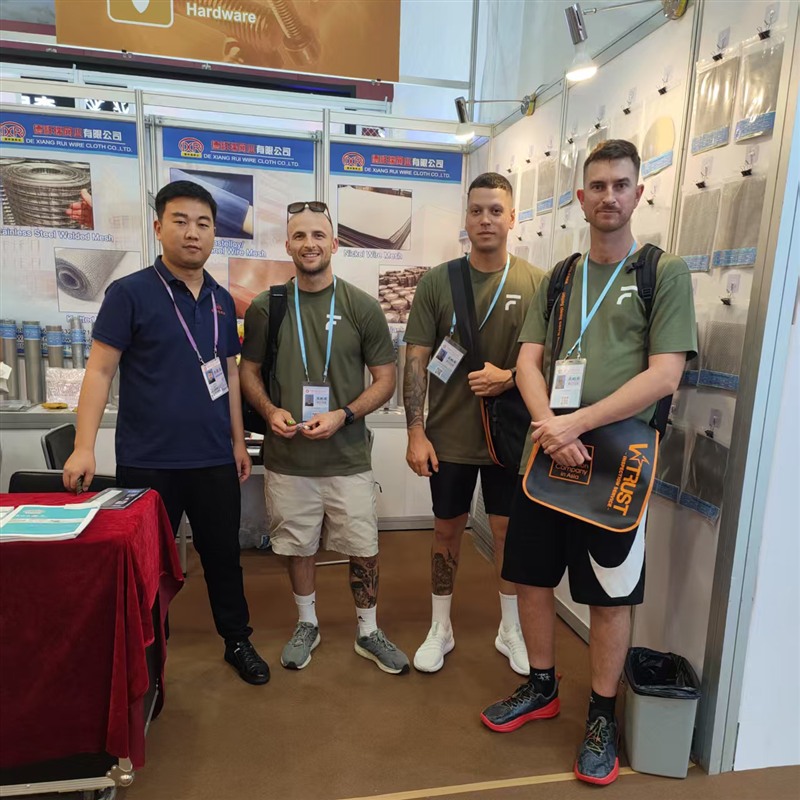

30+years production experience

DXR Wire Mesh is a manufacturing & trading combo of wire mesh and wire cloth in the China.With a track record of over 30 years of business and a technical sales staff with over 30 years of combined experience.

Our Products

DXR's main products are stainless steel wire mesh, filter wire mesh, titanium wire mesh,copper wire mesh, plain steel wire mesh and all kinds of mesh further-processingproducts. Total 6 series, about thousand types of products, widely applied forpetrochemical, aeronautics and astronautics, food, pharmacy, environmentalprotection, new energy, automotive and electronic industry.

In 1988,DeXiangRui Wire Cloth Co, Ltd. was foundedannual value of production is about 30 million US dollars.of which 90% of products delivered to more than 50 countries and regions. DXR brand as a famous brand inHebei Province has been registered in 7 countries aroundthe world for trademark protection.

Customers and Exhibitions

Inside The Factory

Workshop