Hastelloy Wire Mesh

Hastelloy wire mesh is a wire mesh material made of nickel-based corrosion-resistant alloy. It has excellent high temperature resistance, corrosion resistance and oxidation resistance. It is widely used in harsh industrial environments such as chemical industry, petroleum, nuclear facilities, biopharmaceuticals, aerospace, etc.

1. Definition and characteristics

Material composition

Hastelloy wire mesh is mainly composed of elements such as nickel (Ni), chromium (Cr), molybdenum (Mo), and may also contain other metal elements such as titanium, manganese, iron, zinc, cobalt, and copper. The composition of Hastelloy alloys of different grades varies, for example:

C-276: Contains about 57% nickel, 16% molybdenum, 15.5% chromium, 3.75% tungsten, resistant to wet chlorine, oxidizing chlorides and chloride salt solutions.

B-2: Contains about 62% nickel and 28% molybdenum, and has excellent corrosion resistance to strong reducing acids such as hydrochloric acid in a reducing environment.

C-22: Contains about 56% nickel, 22% chromium, and 13% molybdenum, and has good corrosion resistance in both oxidizing and reducing environments.

G-30: Contains about 43% nickel, 29.5% chromium, and 5% molybdenum, and is resistant to corrosive media such as halides and sulfuric acid.

Performance advantages

High temperature resistance: It can work stably for a long time in a high temperature environment and is not easy to deform or soften.

Corrosion resistance: It has excellent resistance to uniform corrosion and intergranular corrosion in wet oxygen, sulfurous acid, acetic acid, formic acid and strong oxidizing salt media.

Anti-oxidation: A dense oxide film can be formed on the surface to prevent further oxidation.

Machinability: It can be woven into wire meshes of different meshes, hole types and sizes to meet diverse needs.

2. Application fields

Hastelloy wire mesh is widely used in the following fields due to its excellent performance:

Chemical and petroleum

Equipment and components used in crude oil hydroprocessing, desulfurization and other links to resist acidic substances and sulfide corrosion.

As a filter component and heat exchanger material in chemical equipment, it is suitable for working conditions containing oxidizing and reducing media.

Nuclear facilities

Used in the filtration and protection systems of nuclear reactors, such as nuclear fuel storage and transportation containers, cooling system filter components, to ensure the safe operation of nuclear facilities.

Biopharmaceuticals

Used in the filtration of fermentation broth and the refining and filtration of raw materials in drug production to prevent the dissolution of metal ions and ensure the purity and safety of drugs.

Aerospace

Manufacturing engine parts and aircraft structural parts to maintain excellent performance under high temperature, high pressure and strong corrosion environment.

Environmental protection field

Used in the absorption tower, heat exchanger, chimney lining or filter components of flue gas desulfurization and denitrification equipment to resist corrosion by acidic gases and particulate matter.

Papermaking industry

Used in containers and equipment for cooking, bleaching and other links to resist corrosion by chemicals in pulp and high temperature environment.

III. Production process

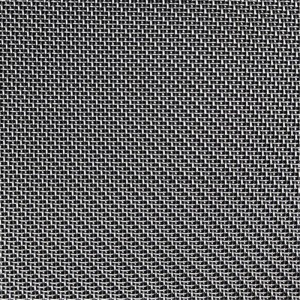

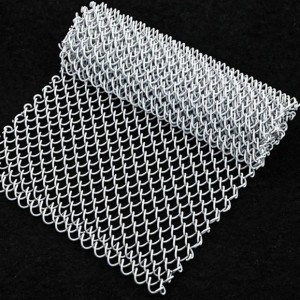

Hastelloy wire mesh adopts the warp and weft cross weaving process, and the specific process is as follows:

Material selection: Select different grades of Hastelloy wire according to needs to ensure that the composition and mechanical properties meet the requirements.

Weaving molding

Hole type design: It can be woven into a variety of hole types such as square holes and rectangular holes.

Mesh range: usually 1-200 meshes are provided to meet different filtration accuracy and ventilation requirements.

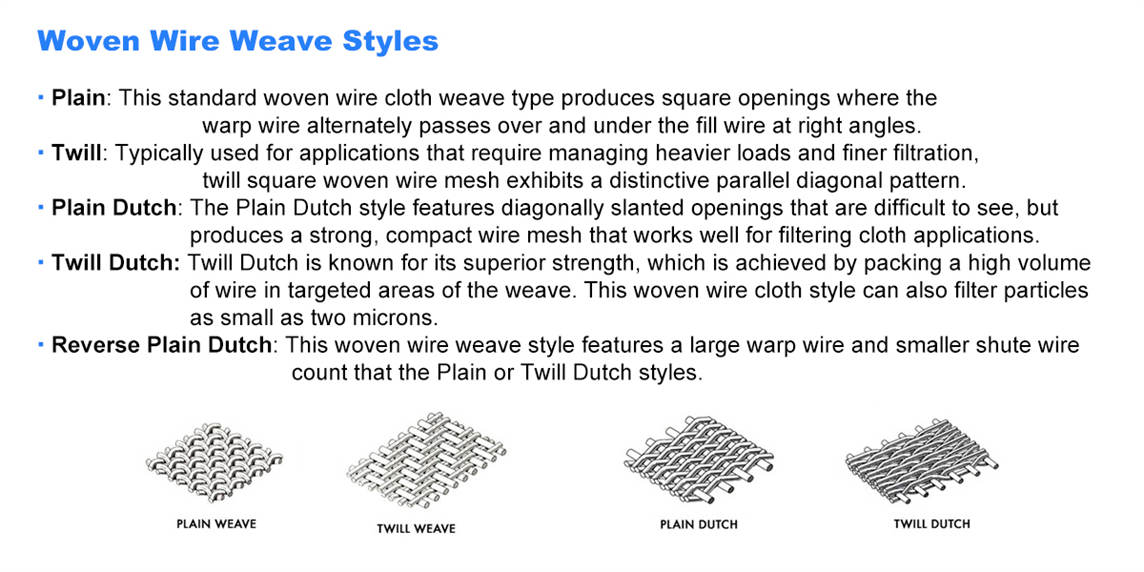

Weaving method: plain weave or twill weave is used to ensure the stability of the wire mesh structure.