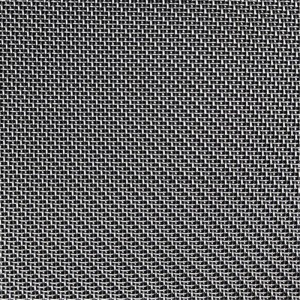

High Precision 200 Mesh SS316 Filter Wire Mesh

Our Precision Stainless Steel Filter Mesh is a high-performance filtration solution engineered for industrial liquid and gas filtration applications. Manufactured with premium-grade stainless steel materials and advanced weaving technology, this filter mesh delivers exceptional durability, precise filtration efficiency, and long service life in the most demanding operating environments.

Material & Specifications

Constructed from food-grade and industrial-grade stainless steel alloys including 304, 316, 304L, and 316L, our filter mesh offers superior corrosion resistance and mechanical strength. The 200 mesh count (approximately 74μm aperture size) with plain weave structure ensures uniform pore distribution and consistent filtration performance. Standard roll widths include 1.2m and 1m with customizable lengths up to 30 meters. We offer various hole shapes including square, rectangular, and special configurations based on specific application requirements.

Exceptional Features

- • Corrosion Resistance: 316L grade stainless steel provides excellent resistance to saltwater, chemicals, and acidic/alkaline solutions

- • High Temperature Tolerance: Sustains stable performance in temperatures ranging from -270°C to +500°C

- • Wear Resistance: Hardened surface treatment ensures minimal abrasion even with high-flow fluids

- • Anti-Rust Properties: Passivated surface prevents oxidation and rust formation

- • Long Service Life: Superior material quality reduces replacement frequency by 30% compared to standard meshes

- • High Filtration Efficiency: 99.9% particle retention rate for specified micron sizes

- • Flat Surface: Precision-calibrated weaving ensures smooth surface for uniform filtration and easy cleaning

Versatile Applications

Our filter mesh finds extensive applications across multiple industries:

- • Petrochemical Industry: Oil, gasoline, and fuel filtration

- • Food & Beverage: Beer, wine, and beverage clarification

- • Water Treatment: Seawater desalination, wastewater purification, and drinking water filtration

- • Chemical Processing: Filtration of acids, alkalis, and chemical reagents

- • Pharmaceutical: Sterile filtration of liquids and solvents

- • Manufacturing: Filtration of polyester liquids, epoxy resin glue, and coating materials

- • Automotive: Fuel and lubricant filtration systems

Manufacturing Advantages

As a leading manufacturer based in Anping County (China’s “Hometown of Wire Mesh”), we leverage:

- • Advanced German weaving machinery and ISO 9001 quality management system

- • Strict material testing including tensile strength, mesh uniformity, and corrosion resistance verification

- • Customization capabilities for non-standard sizes, materials, and specifications

- • Comprehensive quality control from raw material inspection to final product testing

Service & Support

We are committed to providing exceptional customer service:

- • Fast Delivery: 3-5 days for standard products with large stock availability

- • Free Samples: Available for quality evaluation before bulk orders

- • Factory Direct Pricing: Eliminating middlemen for competitive pricing

- • Secure Packaging: Export-standard wooden crates to prevent transportation damage

- • Technical Assistance: Professional engineering support for application-specific solutions

Quality Assurance

Every batch undergoes rigorous testing including dimensional accuracy verification, mesh count inspection, and pressure resistance testing. We provide material certificates and quality reports with each shipment. Our products comply with international standards including ASTM, DIN, and GB/T.

Contact us today for your specific filtration requirements and experience the difference of premium quality filter mesh backed by decades of manufacturing expertise.