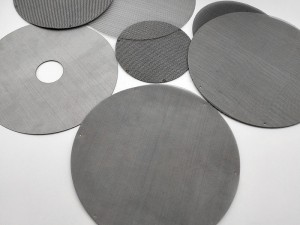

metal mesh discs

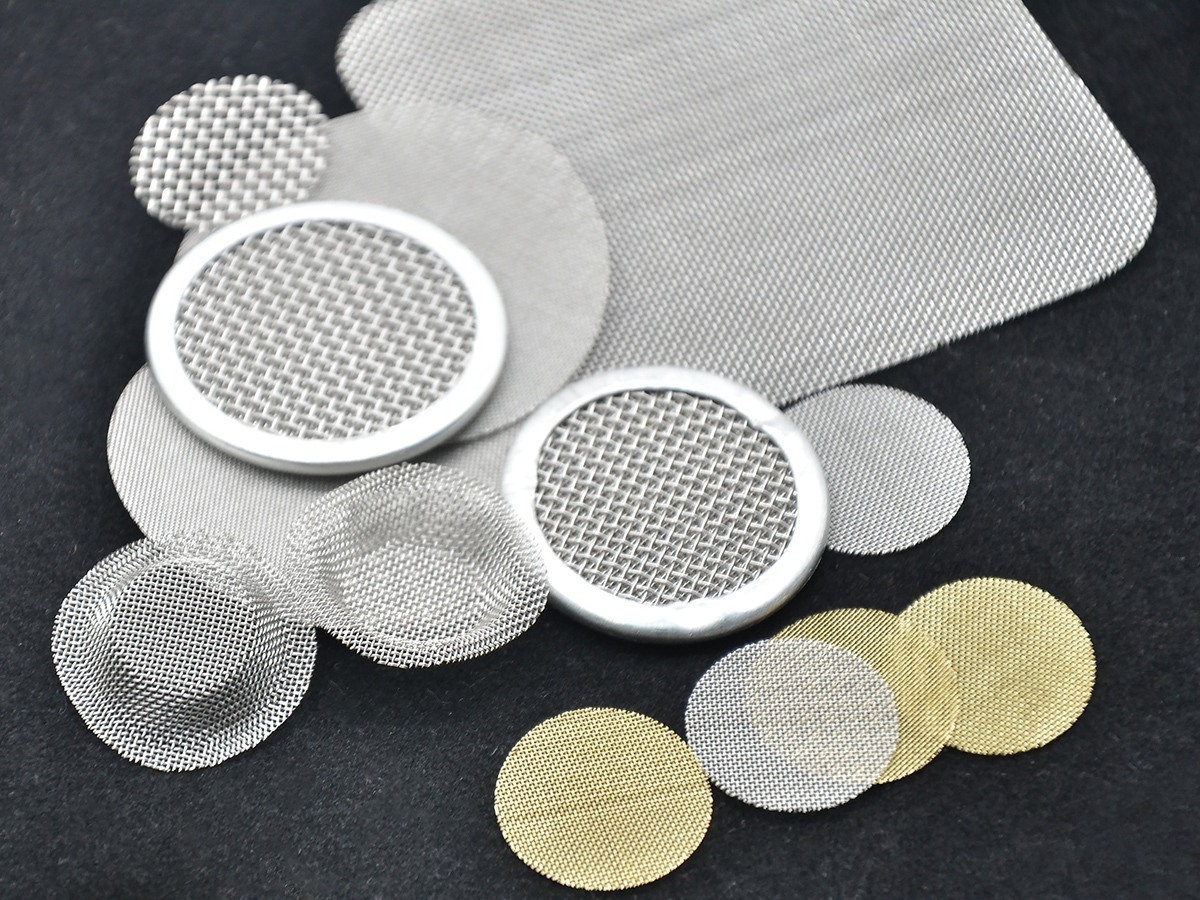

Metal Mesh Discs

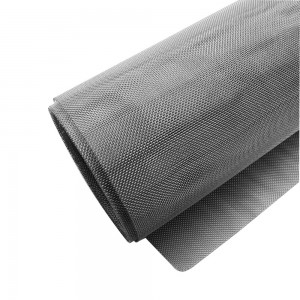

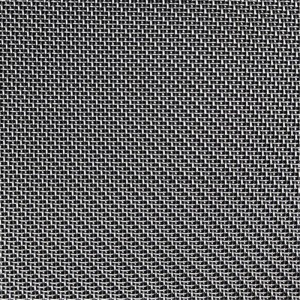

Metal mesh discs is an industrial filter component made of stainless steel, aluminum foil and other metal materials as the base material through weaving, stamping, sintering or wave-shaped lamination. It has the characteristics of high temperature resistance, corrosion resistance, high strength and easy cleaning. It is widely used in petrochemical, air purification, food processing, machinery manufacturing and other fields.

Product Attributes

| Attribute Category | Specific Parameters & Options |

| Primary Material | Stainless Steel (304, 316, 316L), Multi-layer Aluminum Foil, Copper, Specialty Alloys |

| Manufacturing Process | Weaving, Stamping, Sintering, Wave-Shaped Lamination |

| Standard Diameter | Customizable from 10 mm to 1200 mm (or as per customer drawing) |

| Thickness (Profile) | 0.5 mm to 6 mm (varies significantly by material and process) |

| Filtration Rating / Micron | Available from 1 micron (fine filtration) to 500+ microns (coarse straining) |

| Pore Shape & Structure | Square mesh (woven), round holes (stamped), 3D porous matrix (sintered), corrugated channels (laminated) |

| Surface Treatment | Electroplating, Passivation, Painting, Powder Coating (for enhanced corrosion resistance or aesthetics) |

| Frame / Edge Detail | Unframed (disc only), Rolled Edge, Welded Frame (Galvanized Steel, Aluminum Alloy, Stainless Steel) |

| Key Performance Traits | High Temperature Resistance, Acid/Alkali Corrosion Resistance, High Mechanical Strength, Fire Retardant, Reusable/Cleanable |

| Typical Industry Applications | Petrochemical, Food & Beverage Processing, Pharmaceutical, Machinery Hydraulics, HVAC & Air Purification, Automotive Manufacturing |

Precision Processes

Produces a uniform mesh with consistent pore size and excellent permeability.

Creates a robust, perforated plate structure known for high strength and cost-effectiveness.

Bonds multiple layers of metal mesh at high temperature to form a rigid, porous monolithic structure ideal for high-pressure differentials and extreme conditions.

A specialized process where foil or mesh is corrugated and layered crosswise. This innovative design forces fluid to change direction multiple times, dramatically increasing particle capture efficiency without proportionally increasing resistance.

High-Efficiency Filtration

The multi-layer, often wave-laminated structure creates a depth-loading effect, capturing particles throughout the media volume. A density gradient arrangement (coarse to fine) increases dust holding capacity by approximately 40% while reducing initial resistance by 15-20%.

Exceptional Durability and Safety

Built from inherently robust metals, these discs withstand wear, aging, and demanding cycles. Their high-temperature and corrosion-resistant nature extends service life to 2-3 times that of conventional filters. Crucially, they possess excellent fire-retardant properties, certified to standards like GB/T 5169, ensuring safety in critical environments.

Operational Economy

The rigid, plate-type structure is easy to handle, clean (often reusable), and maintain. They support user-independent replacement, minimizing downtime and labor costs over their long service life.

Versatile Applications Across Core Industries

• Industrial Filtration: For separating, purifying, and concentrating process streams in petrochemical plants (distillation, absorption). They protect sensitive equipment in machinery manufacturing (hydraulic and lubrication systems) and ensure purity in food and beverage processing.

• Air Purification & HVAC: Serving as durable pre-filters or main filters in central air conditioning and ventilation systems, capturing large particulate matter (>10 microns). They are ideal for cleanrooms, painting booths, and high-temperature environments like metallurgical plants, protecting higher-stage filters and ensuring air quality.

• Specialized Scenarios: Used for oil mist filtration in automotive spray shops, ensuring clean air in electronics manufacturing cleanrooms, and providing sanitary ventilation in pharmaceutical and bio-product facilities.

Commitment to Precision and Customization

Every disc is manufactured with stringent quality control. We offer extensive customization, including non-standard diameters, thicknesses, micron ratings, and the choice of outer frames (galvanized steel, aluminum alloy, etc.), ensuring a perfect fit and function for your unique system requirements.

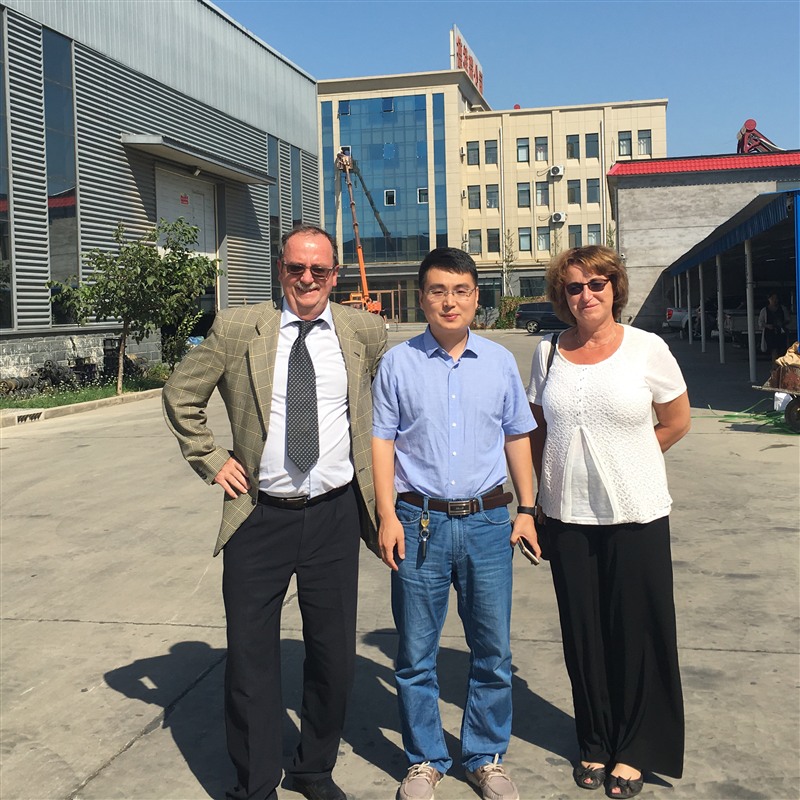

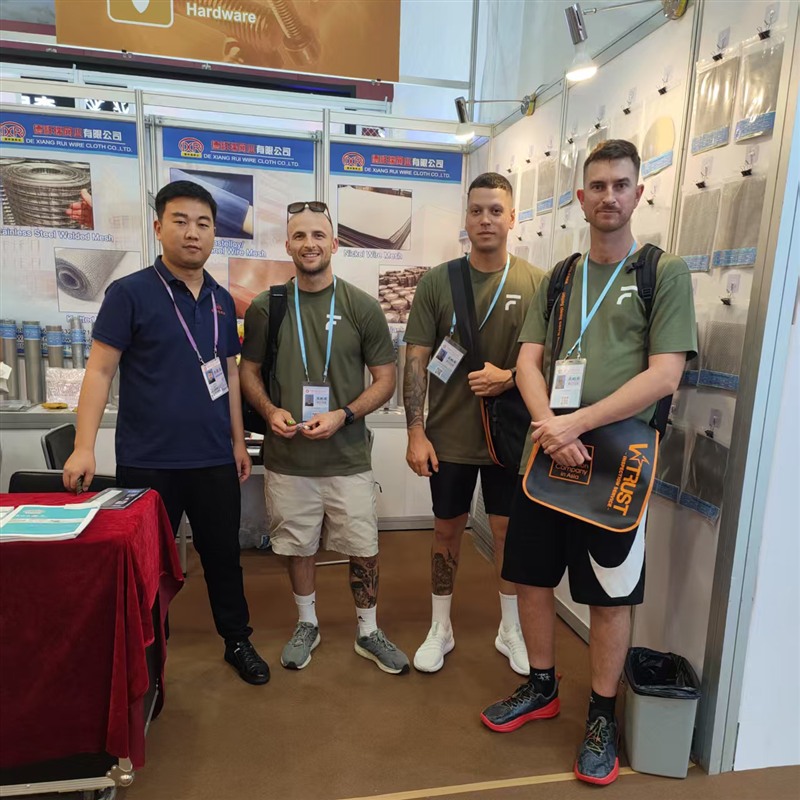

30+years production experience

DXR Wire Mesh is a manufacturing & trading combo of wire mesh and wire cloth in the China.With a track record of over 30 years of business and a technical sales staff with over 30 years of combined experience.

Our Products

DXR's main products are stainless steel wire mesh, filter wire mesh, titanium wire mesh,copper wire mesh, plain steel wire mesh and all kinds of mesh further-processingproducts. Total 6 series, about thousand types of products, widely applied forpetrochemical, aeronautics and astronautics, food, pharmacy, environmentalprotection, new energy, automotive and electronic industry.

In 1988,DeXiangRui Wire Cloth Co, Ltd. was foundedannual value of production is about 30 million US dollars.of which 90% of products delivered to more than 50 countries and regions. DXR brand as a famous brand inHebei Province has been registered in 7 countries aroundthe world for trademark protection.

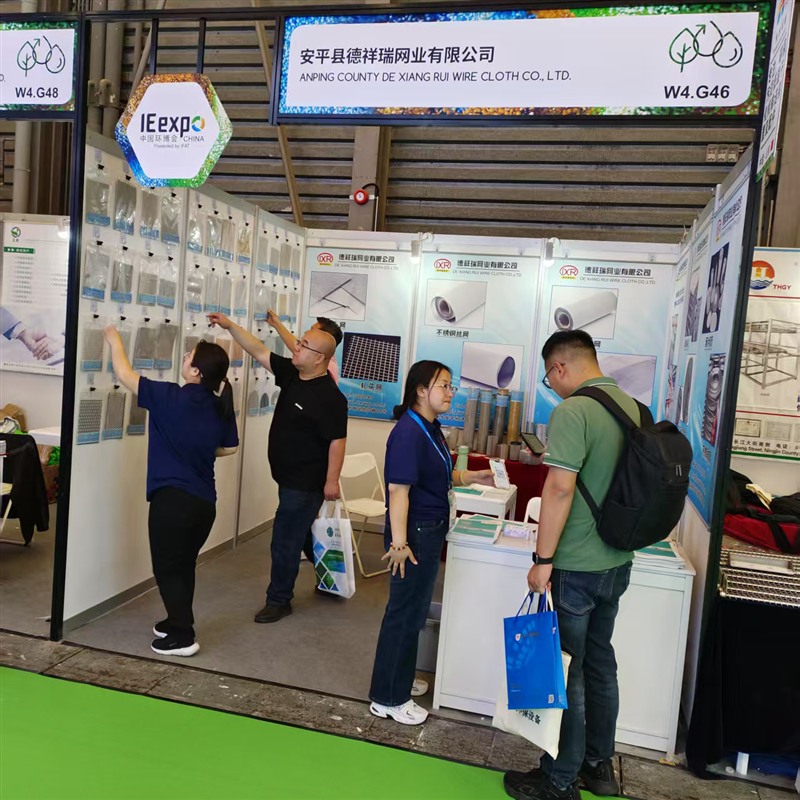

Customers and Exhibitions

Inside The Factory

Workshop

Production Machine

FAQ

Q1: Is it all right to make customer's own brand name?

A: Yes, we offer OEM service.

Q2: Are you a manufactuer or trading company?

A: We are a professional manufacturer since 1988.

Q3: Can you do the design for us?

A: Yes,Both design and customization are available

Q4: How can I get a sample to check your quality?

A: Please send us an email to sales88@china-wiremesh.net or contact us through this website. We will arrange samples via DHL, FedEx, UPS etc.

Q5: Is the sample free,and How long can I expect to get the sample?

A: Although we support free sample, you need pay the freight.It depends on your address how long it will take to receive it. We can do all the sample in 2 days

Q6: Packaging & Shipping:

A: "Water-proof paper,plastic film, wooden cases or pallets outside.

By sea, train, sea and air. "

Q7: What about the lead time for mass production?

A: Common specifications within 30 days

Q8: Where is your loading port?

A: Tianjin, Qingdao

Q9: How long is the delivery period of the product?

A: 2-30 days

Q10: What quality certifications do you have?

A: CE, ISO 9001:2015, SGS