Most people are unaware of this, but some people are allergic to metals. According to background information published in a new article, ten percent of the German population is allergic to nickel.

But medical implants use nickel. Nickel-titanium alloys are increasingly being used as materials for cardiovascular implants in minimally invasive procedures, and after implantation, these alloys release small amounts of nickel due to corrosion. Is it dangerous?

A group of researchers from Jena, Prof. Rettenmayr and Dr. Andreas Undis, report that wires made from a nickel-titanium alloy emit very little nickel, even over long periods of time. The test period for metal release is only a few days, as required by the government for medical implant approval, but Jena’s research team observed the nickel release for eight months.

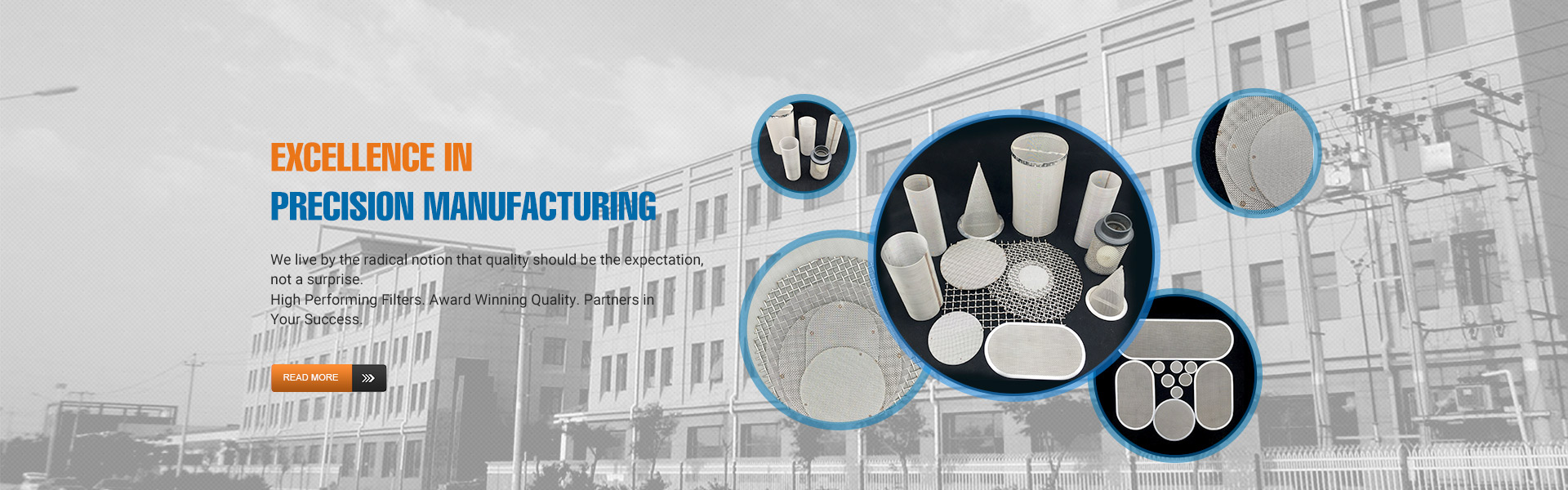

The object of the study is a thin wire made of a superelastic nickel-titanium alloy, which is used, for example, in the form of an occluder (these are medical implants used to repair a heart septal defect). An occluder usually consists of two tiny wire mesh “umbrellas” about the size of a euro coin. The superelastic implant can be mechanically pulled into a thin wire that can then be placed in a cardiac catheter. “In this way, the occluder can be placed with a minimally invasive procedure,” Undisch said. Ideally, the implant will remain in the patient for years or decades.

Occluder made of nickel-titanium alloy. These medical implants are used to repair a defective heart septum. Credit: Photo: Jan-Peter Kasper/BSS.

Undis and doctoral student Katarina Freiberg wanted to find out what happened to the nickel-titanium wire during this time. They subjected wire samples with various mechanical and thermal treatments to ultrapure water. They then tested the nickel release based on predetermined time intervals.

“This is not at all trivial,” says Undish, “because the concentration of the metal released is usually at the limit of detection.” , succeeded in developing a robust test procedure for measuring the nickel release process.

“In general, in the first days and weeks, depending on the pre-treatment of the material, a significant amount of nickel can be released,” Undisch summarizes the results. According to materials scientists, this is due to the mechanical load on the implant during the operation. “Deformation destroys the thin layer of oxide covering the material. The result is an increase in initial nickel recovery.” nickel we absorb through food every day amount.

In Science 2.0, scientists are journalists, without political bias or editorial control. We cannot do this alone, so please do your part.

We are a non-profit, Section 501(c)(3) science news corporation that educates more than 300 million people.

You can help make a tax-free donation today and your donation will go 100% to our programs, no salary or office.

Post time: Apr-14-2023