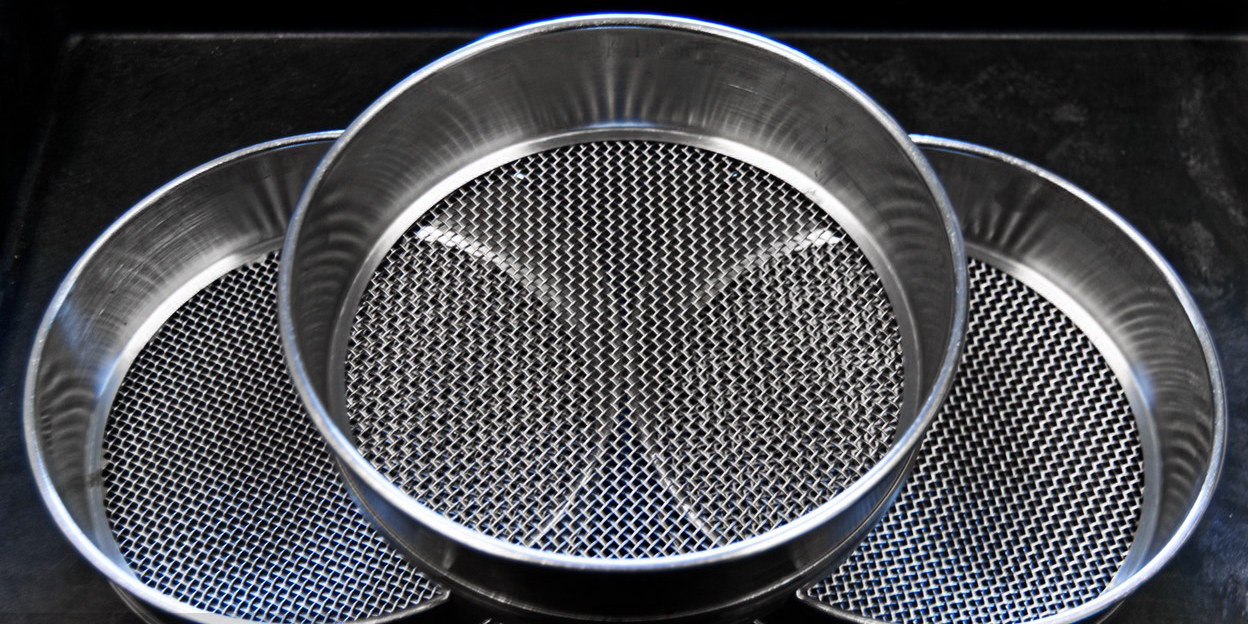

Precision Medical Test Sieves

Product Description

Our Medical Test Sieves are precision-engineered for accurate particle size analysis in pharmaceutical and medical industries. Manufactured in compliance with ISO 3310-1/2 and ASTM E11 standards, each sieve comes with individual calibration certificates for guaranteed traceability and reliability in quality control processes.

Product Attributes

| Attribute | Specification |

|---|---|

| Product Type | Woven Wire Mesh Sieves, Perforated Plate Sieves |

| Compliant Standards | ISO 3310-1&2, ASTM E11, BS 410 |

| Aperture Range | Wire Mesh: 20µm - 125mm; Perforated Plate: 1mm - 125mm |

| Frame Material | Stainless Steel, Brass, Plated Steel |

| Frame Diameter | 3", 8", 12", 18" (ASTM); 100mm, 200mm, 300mm, 450mm (ISO) |

| Mesh Material | Stainless Steel, Brass |

| Certification | Individual Calibration Certificate, Certificate of Conformity |

| Key Features | Balanced Tension Mesh, Seamless Construction, Laser-Marked Serial Number |

| Typical Applications | Pharmaceutical Powder Analysis, Medical Granule Sampling, QA/QC Laboratories |

Product Applications

Pharmaceutical Manufacturing:

- • Particle size analysis of Active Pharmaceutical Ingredients (APIs)

- • Quality control of excipients (e.g., lactose, cellulose)

- • Granule size distribution testing for tablet compression

- • Sieve analysis of powdered drug formulations

Medical Device & Implants:

- • Size classification of ceramic or polymer beads for implants

- • Quality control of metal powder for additive manufacturing (3D printing)

- • Testing the granular consistency of bio-composite materials

Research & Development:

- • R&D labs for new drug formulation development

- • University and clinical research on biomaterials

- • Conducting method development and validation studies

Quality Control & Testing Labs:

- • In-process quality control checks during manufacturing

- • Raw material inspection and certification

- • Ensuring batch-to-batch consistency and regulatory compliance

Unmatched Precision And Accuracy

The balanced tensioning of the mesh ensures consistent, reliable results and an extended operational lifespan without distortion.

Superior Durability & Construction

The seamless construction between the mesh and frame prevents sample loss and contamination, while the deburred edges ensure safe and comfortable handling.

Optimized for Performance

The robust design minimizes particle trapping and simplifies cleaning, enhancing workflow efficiency.

30+years production experience

DXR Wire Mesh is a manufacturing & trading combo of wire mesh and wire cloth in the China.With a track record of over 30 years of business and a technical sales staff with over 30 years of combined experience.

Our Products

DXR's main products are stainless steel wire mesh, filter wire mesh, titanium wire mesh,copper wire mesh, plain steel wire mesh and all kinds of mesh further-processingproducts. Total 6 series, about thousand types of products, widely applied forpetrochemical, aeronautics and astronautics, food, pharmacy, environmentalprotection, new energy, automotive and electronic industry.

In 1988,DeXiangRui Wire Cloth Co, Ltd. was foundedannual value of production is about 30 million US dollars.of which 90% of products delivered to more than 50 countries and regions. DXR brand as a famous brand inHebei Province has been registered in 7 countries aroundthe world for trademark protection.

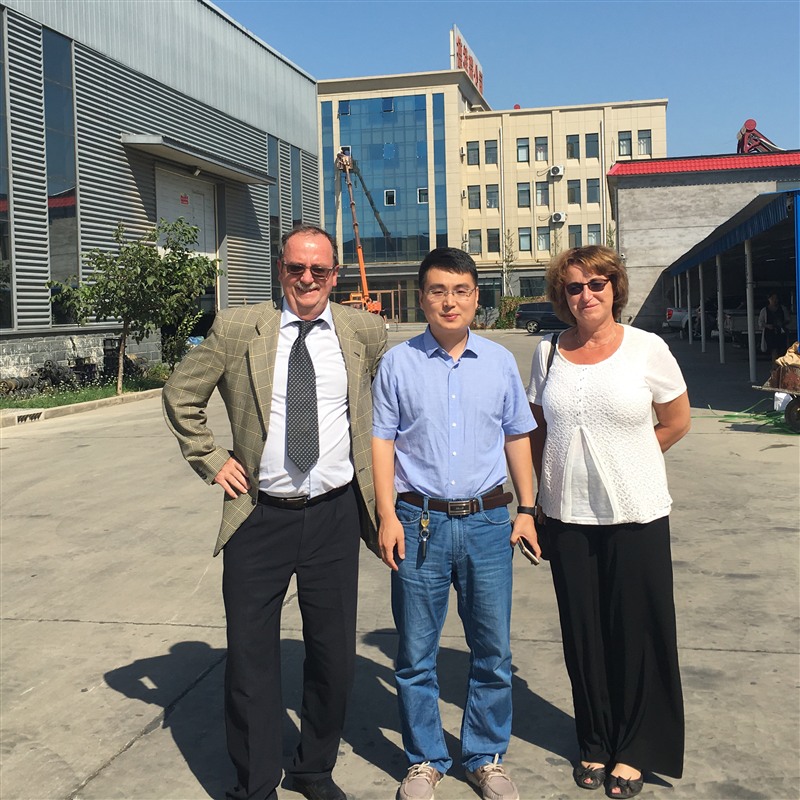

Customers and Exhibitions

Inside The Factory

Workshop