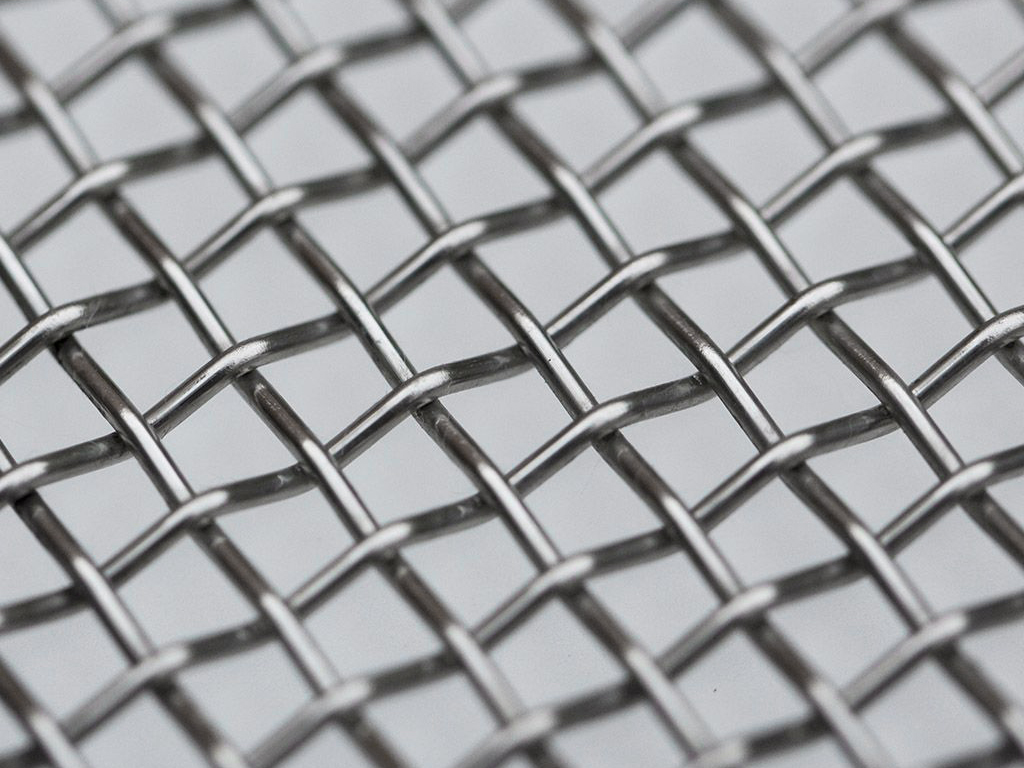

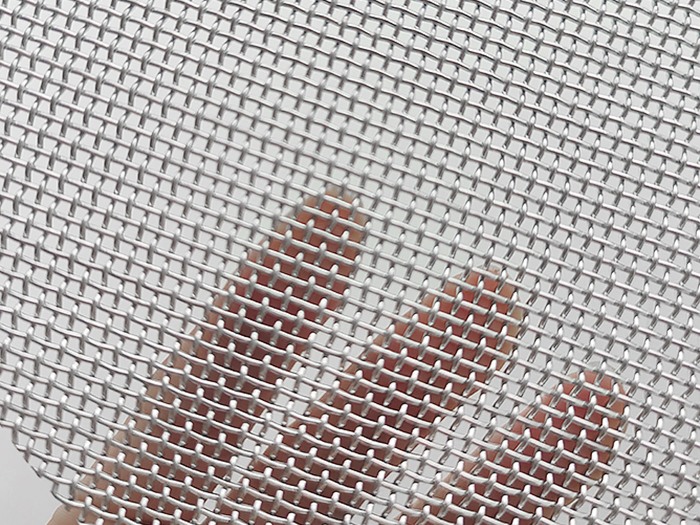

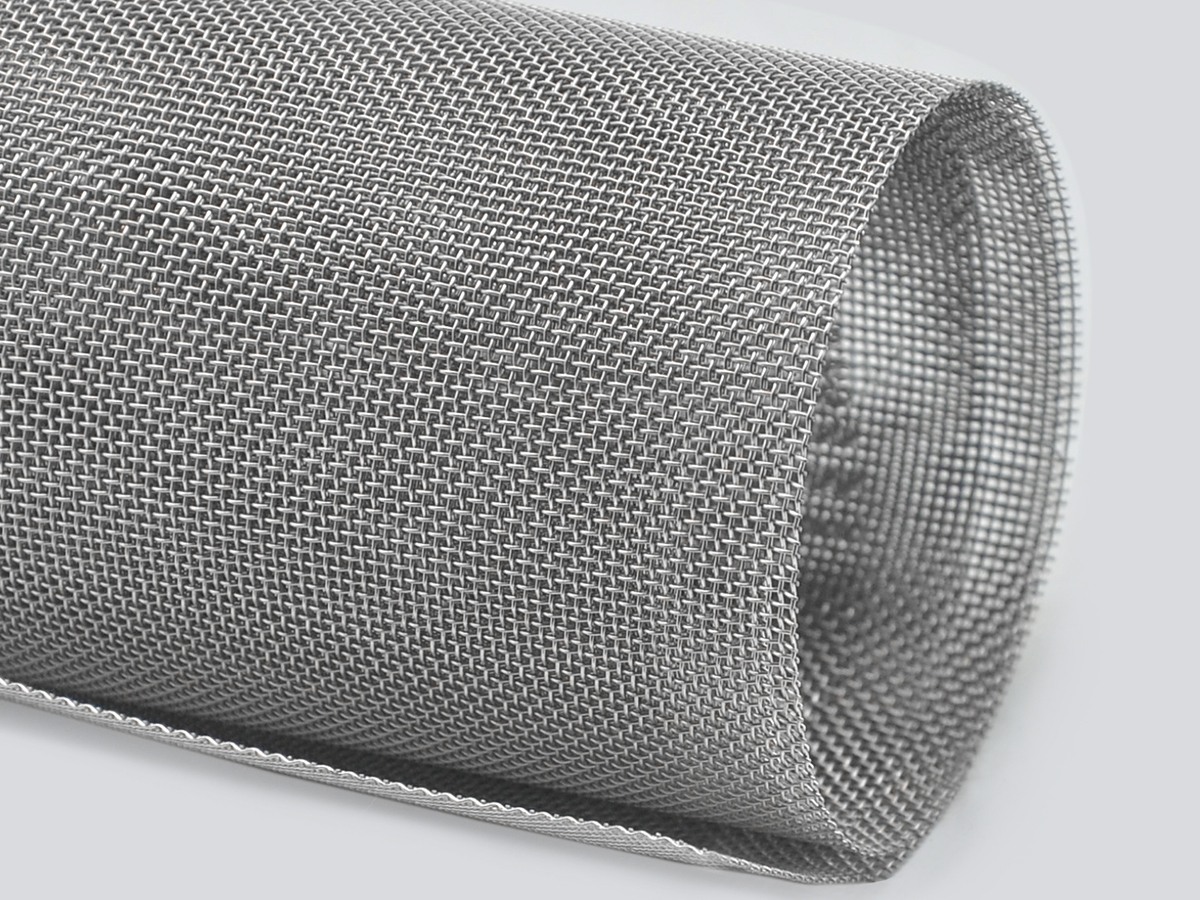

Premium Stainless Steel Wire Mesh – Precision Woven

Premium Stainless Steel Wire Mesh – Precision Woven

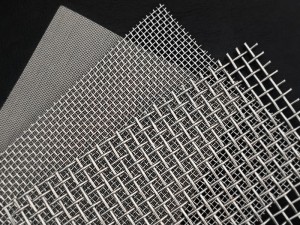

Multiple weaving techniques (Plain, Twill, Dutch) cater to everything from coarse screening to ultra-fine filtration.

Exceptional accuracy: Twill weave offers ±2% filtration precision, while Dutch weave achieves filtration down to 2μm.

The warp yarns are inclined and interwoven, intersecting every two times. It has good flexibility, strong resistance to deformation, and is suitable for vibrating screens and catalyst filtration (100-635 mesh)

The warp yarns are thicker and the weft yarns are thinner, with a dense structure.

Product Attributes

| Category | Attribute / Parameter | Description / Value | Details / Notes |

| Core Materials | Primary Grades | AISI 304, AISI 316L, 2205 Duplex | 304: General purpose. 316L: Superior corrosion resistance. 2205: For high-chloride environments. |

| Material Composition (Typical) | 304: 18% Cr, 8% Ni | Molybdenum (Mo) content is key for pitting & chloride resistance. | |

| 316L: 16-18% Cr, 10-14% Ni, 2-3% Mo | |||

| 2205: ~22% Cr, 5-6% Ni, 3% Mo | |||

| Weaving Types & Structure | Plain Weave | Warp and weft wires are the same diameter, woven over and under each other. | Characteristics: Flat surface, high strength, cost-effective, high open area (56-84%). |

| Typical Mesh: 1 - 400 | |||

| Twill Weave (Diagonal) | Warp wires pass over and under two weft wires, creating a diagonal pattern. | Characteristics: Excellent flexibility, high deformation resistance, good flow rate. | |

| Typical Mesh: 100-635. | |||

| Dutch Weave (Plain Dutch / Dutch Twill) | Warp wires are thicker than weft wires, woven in a dense, tight pattern. | Characteristics: Very smooth surface, high strength, capable of micron-level filtration. | |

| Filtration Rating: Down to 2μm. | |||

| Physical Parameters | Mesh Count | 1 to 635 Mesh | Range from coarse screening to ultra-fine filtration. |

| Wire Diameter | 0.03mm to 2.5mm+ (Customizable) | Varies based on mesh count and weave type. Thicker wires offer more strength. | |

| Aperture / Opening Size | 23.37mm (coarse) to 0.02mm (fine) | The clear space between wires. Determines particle retention. | |

| Open Area | Up to 84% (Plain Weave) | Percentage of open space vs. total area. Affects flow rate and light transmission. |

Core advantages

It is made of high-quality 304/316L stainless steel wire

Excellent corrosion resistance

The 304 material contains 18% chromium + 8% nickel, capable of withstanding weak acid and weak alkali environments; the 316L adds 2-3% molybdenum, enhancing its chlorine corrosion resistance by 50%, passing the ASTM B117 salt spray test for 96 hours without rust (316L), suitable for high-corrosion scenarios such as marine and chemical industries.

Precise weaving technology

Supports plain weave (uniform mesh, high strength), twill weave (good flexibility, filtration accuracy ±2%), Dutch weave (design with different diameters of warp and weft threads, filtration accuracy up to 2μm), with a mesh range of 1-635 meshes, meeting the needs from coarse screening to ultra-fine filtration in all scenarios.

Industry-wide applicability

Certified by ISO 9001:2015 quality standard, food-grade products comply with FDA 21 CFR 177.2600 standards, widely used in petroleum, medicine, construction, environmental protection and 20+ other industries.

Industry application scenarios

• Petrochemical industry

▫ Drilling mud filtration: 8-mesh plain weave net (wire diameter 2.03mm, hole diameter 23.37mm), intercepting rock debris particles, increasing the slurry processing capacity by 30%.

▫ Catalyst screening: 325-mesh Dutch woven net (wire diameter 0.035mm, hole diameter 0.043mm), ensuring the uniformity of catalyst particles ≥ 98%.

• Pharmaceuticals and food

▫ Antibiotic filtration: 500-mesh diagonal weave net made of 316L material, GMP certified, sterilization efficiency ≥ 99.9%.

▫ Juice clarification: 100-mesh 304 plain weave net (wire diameter 0.64mm, hole diameter 1.91mm), filtering out fruit pulp impurities, increasing light transmittance by 40%.

•

• Facade protection system

10-mesh plain weave net (wire diameter 1.6mm, hole diameter 11.1mm), combined with aluminum alloy frame, having both anti-theft (impact resistance 1100N) and light transmission (opening rate 76.4%) functions, suitable for commercial complex exterior walls.

• Interior artistic partition

200-mesh diagonal dense weave net (wire diameter 0.05mm, hole diameter 0.07mm), surface electrolytic polishing (Ra ≤ 0.4μm), used for high-end hotel screens, with unique light and shadow effects.

• Municipal sewage treatment

304 material 1-5mm aperture net, intercepting suspended solids (SS removal rate ≥ 90%), used in combination with biological filter tanks, improving treatment efficiency by 25%.

• Seawater desalination

2205 duplex steel net (resistant to Cl⁻ concentration 20000ppm), used for pre-treatment of reverse osmosis systems, reducing membrane contamination rate by 40%.

30+years production experience

DXR Wire Mesh is a manufacturing & trading combo of wire mesh and wire cloth in the China.With a track record of over 30 years of business and a technical sales staff with over 30 years of combined experience.

Our Products

DXR's main products are stainless steel wire mesh, filter wire mesh, titanium wire mesh,copper wire mesh, plain steel wire mesh and all kinds of mesh further-processingproducts. Total 6 series, about thousand types of products, widely applied forpetrochemical, aeronautics and astronautics, food, pharmacy, environmentalprotection, new energy, automotive and electronic industry.

In 1988,DeXiangRui Wire Cloth Co, Ltd. was foundedannual value of production is about 30 million US dollars.of which 90% of products delivered to more than 50 countries and regions. DXR brand as a famous brand inHebei Province has been registered in 7 countries aroundthe world for trademark protection.

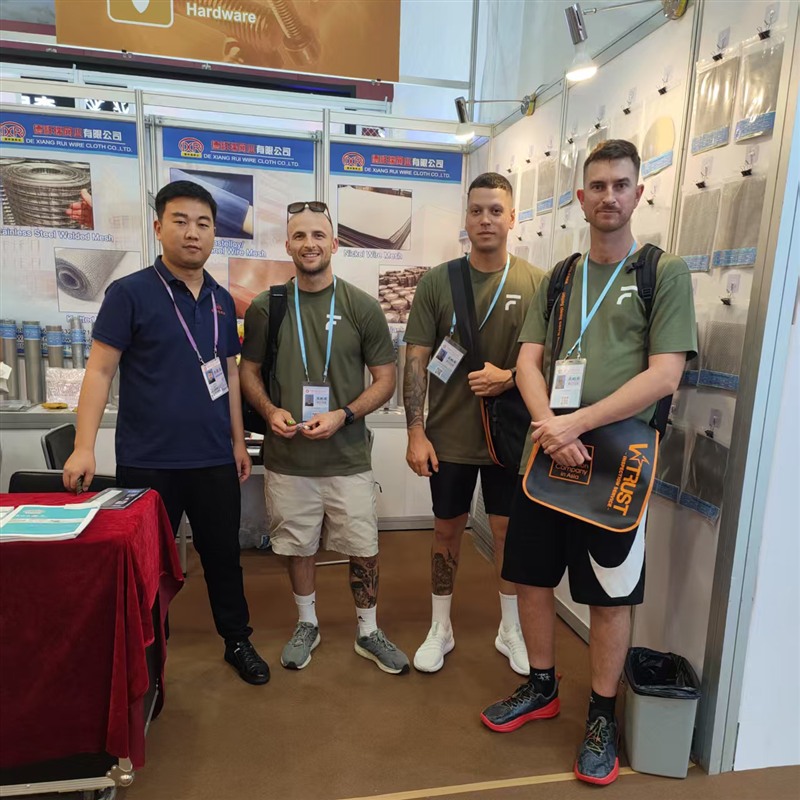

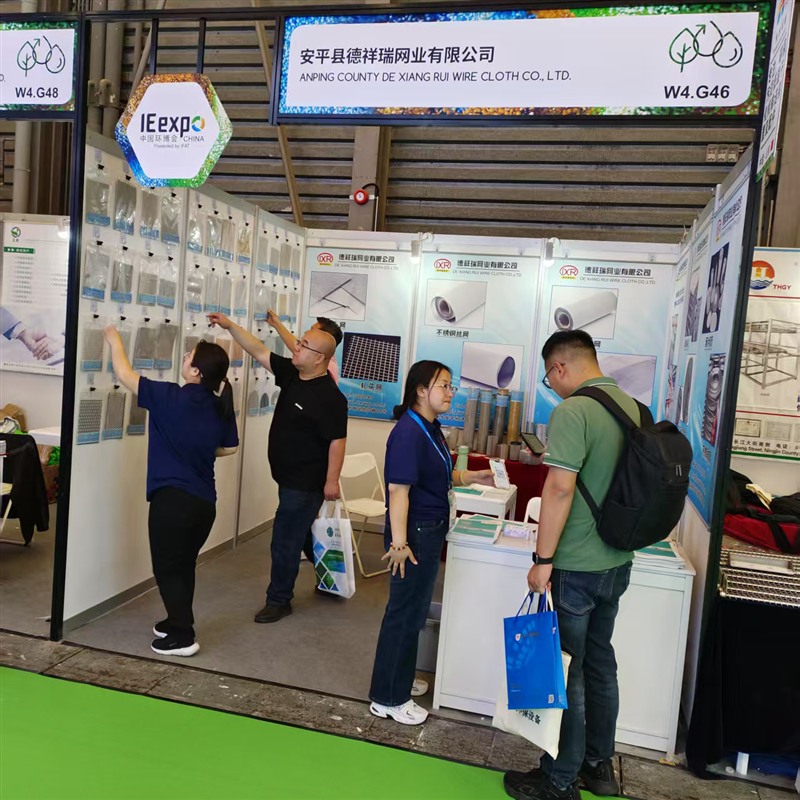

Customers and Exhibitions

Inside The Factory

Workshop

Production Machine

FAQ

Q1: Is it all right to make customer's own brand name?

A: Yes, we offer OEM service.

Q2: Are you a manufactuer or trading company?

A: We are a professional manufacturer since 1988.

Q3: Can you do the design for us?

A: Yes,Both design and customization are available

Q4: How can I get a sample to check your quality?

A: Please send us an email to sales88@china-wiremesh.net or contact us through this website. We will arrange samples via DHL, FedEx, UPS etc.

Q5: Is the sample free,and How long can I expect to get the sample?

A: Although we support free sample, you need pay the freight.It depends on your address how long it will take to receive it. We can do all the sample in 2 days

Q6: Packaging & Shipping:

A: "Water-proof paper,plastic film, wooden cases or pallets outside.

By sea, train, sea and air. "

Q7: What about the lead time for mass production?

A: Common specifications within 30 days

Q8: Where is your loading port?

A: Tianjin, Qingdao

Q9: How long is the delivery period of the product?

A: 2-30 days

Q10: What quality certifications do you have?

A: CE, ISO 9001:2015, SGS