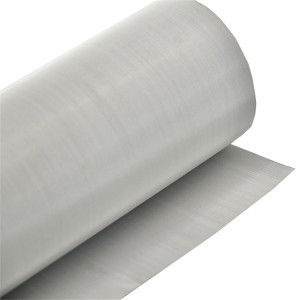

Stainless Steel Sintered Mesh

Superior Engineering for Demanding Applications

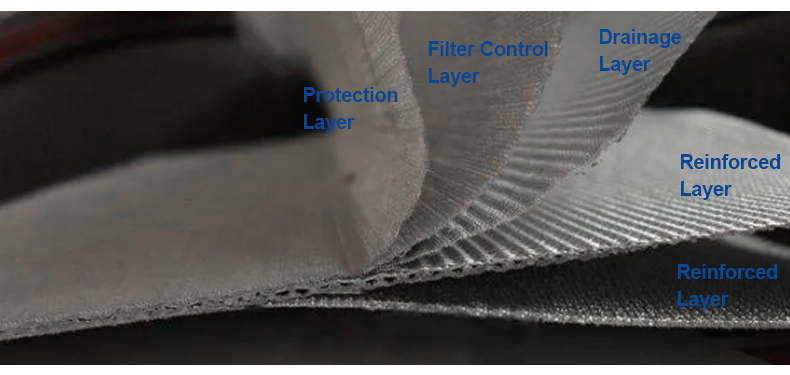

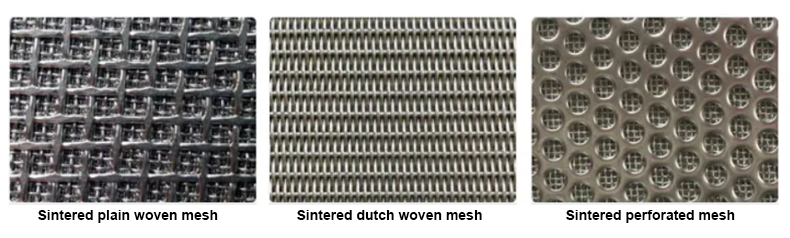

Our sintered mesh is manufactured by diffusion-bonding multiple layers of stainless steel wire mesh under high temperature in a vacuum furnace. This robust manufacturing process creates a porous structure with exceptional mechanical strength, high rigidity, and stable pore shape that outperforms standard wire cloth. The standard five-layer construction includes a protective layer, precision control layer, dispersion layer, and multiple strengthening layers, working together to deliver unmatched filtration reliability.

Key Features and Technical Advantages

-

Exceptional Durability & Strength: The sintered layers form a monolithic material with high mechanical strength and compressive resistance, capable of withstanding challenging operational conditions and repeated cleaning cycles.

-

High and Stable Filtration Precision: With a controllable filtration range typically from 2 to 200 micrometers (and up to 300μm), our mesh provides consistent, surface-level filtration performance. Its uniform pore structure ensures reliable particle capture.

-

Excellent Thermal and Corrosion Resistance: Ideal for high-temperature environments, our sintered mesh operates effectively in a wide temperature range from -200°C to 650°C. Its stainless steel composition offers strong resistance to corrosion in various chemical environments.

-

High Porosity and Low Pressure Drop: The material’s structure achieves high porosity, which allows for high flow rates with a very low pressure drop. This translates to lower energy consumption and increased efficiency in filtration systems.

-

Easy Cleaning and Reusability: The surface filtration mechanism, combined with the material’s strength, allows for effective backwashing or reverse cleaning. This feature extends the product’s service life, making it a cost-effective solution.

Customization and Versatility

We understand that distributors serve diverse client needs. Therefore, we offer extensive customization options:

-

Material Selection: Primarily SUS304, SUS304L, SUS316, and SUS316L, with other alloys available upon request.

-

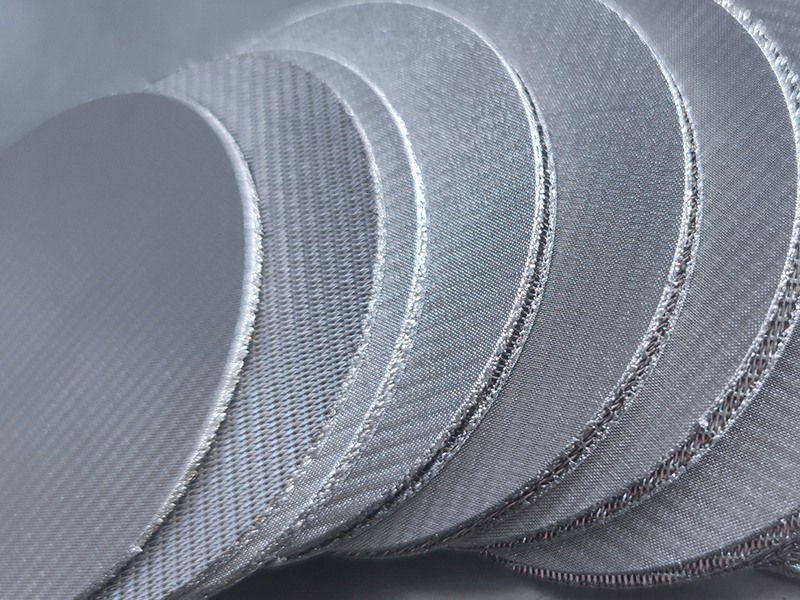

Size and Shape: Customized in terms of length, width, and shape (round, square, or as required), with standard sheet sizes also available.

-

Specifications: We can tailor thickness (from 0.2mm to 10mm), filtration accuracy, and number of layers (e.g., three-layer, five-layer, multilayer) to meet specific application requirements.

-

OEM Services: We support OEM services, including custom branding and packaging, to help you build your product line.

Broad Application Spectrum

Our sintered mesh is versatile and serves a wide range of industries, creating multiple channels for sales:

-

Chemical & Petrochemical: For filtering polymers, corrosive liquids, and catalysts.

-

Oil & Gas: Used in hydraulic oil filtration, high-pressure backwash oil filters, and fuel filtration.

-

Food & Pharmaceutical: Suitable for processing food, beverages, and pharmaceutical ingredients where hygiene and corrosion resistance are critical.

-

Power, Cement, and Mining: Applied in gas diffusion, fluidized bed plates, and high-temperature air filtration.

-

Machinery and Manufacturing: Excellent for filtering various hydraulic and lubricating oils, as well as protecting equipment in metalworking and automotive applications.

A Reliable Partner for Distributors

As a manufacturer, we are committed to supporting your business growth. We offer reliable supply capacity, competitive pricing, and robust technical support. Our products are backed by quality assurances and warranties, ensuring you can source with confidence and build long-term partnerships with your clients.