When stainless steel wire mesh is used as a stainless steel filter mesh, it can block the small diameter size of most solid particles, which is called the filtration degree of stainless steel wire mesh.

The filtration of a stainless steel wire mesh is its mesh size. The actual value of the mesh size directly affects the degree of filtering. There are three types of stainless steel screens: normal filtration degree, filtration degree, and actual filtration degree.

Normal filtration degree (also normal size): refers to the cross section of the woven circular stainless steel dense mesh, the inscribed circle diameter of the triangular hole composed of warp and weft. Filtration degree (also called aperture): refers to the cross section of the twill weave dense mesh, the diameter of the large inscribed circle of the inclined surface of the adjacent two weft wires and the warp wire forming the triangular hole. Actual filtration degree: refers to the degree of filtration of stainless steel wire mesh under actual use conditions.

For a specific specification of stainless steel wire mesh, the actual filtration degree of the stainless steel wire mesh of the same specification changes accordingly when the conditions of use change.

The actual filtration degree of the dutch weave wire mesh is directly affected by the use conditions such as temperature, differential pressure, length of use, viscosity of the medium, and bending times of the filter holes. Therefore, the actual filtration degree is a variable value.

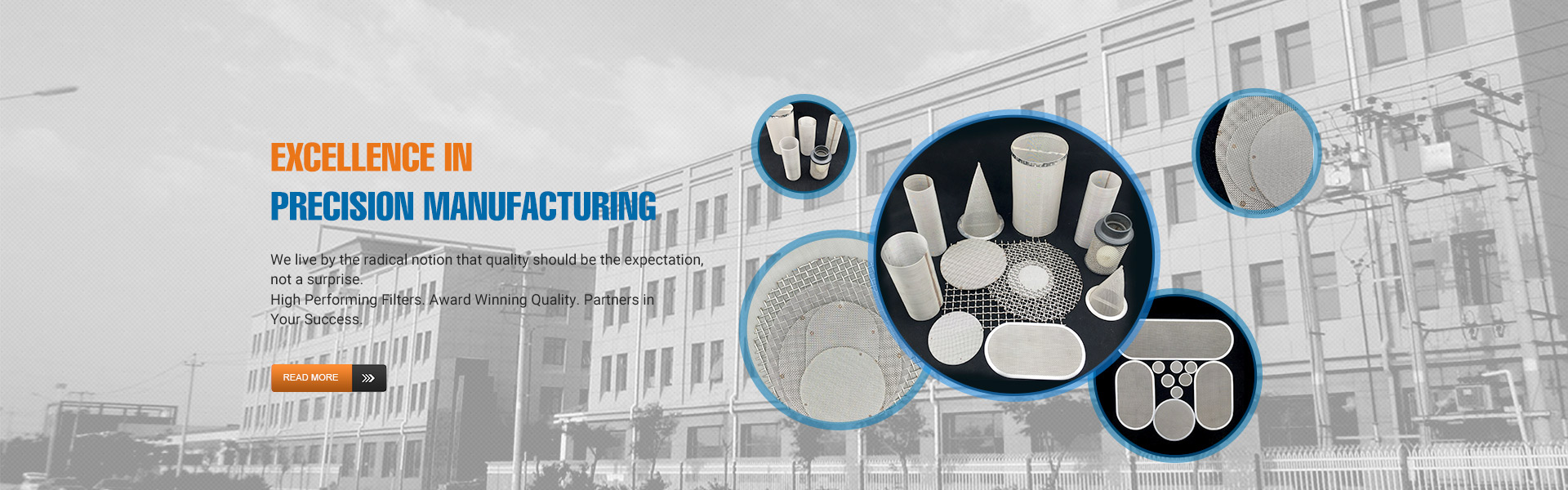

Stainless steel wire mesh is the main material for high-precision product filtration. It can be processed into filters, filter cartridges, filter cartridges, etc. It is widely used in aerospace, petroleum, chemical, pharmaceutical, food, mining, printing, automotive, mobile phones and many other industries.

Stainless steel wire mesh is corroded due to its special metallographic structure and surface passivation film, which is difficult to chemically react with the medium under normal conditions, but it cannot be corroded under any conditions. In the presence of corrosive media and incentives (such as scratches, splashes, slag, etc.), stainless steel wire mesh can also be corroded by slow chemical and electrochemical reactions with corrosive media, and the corrosion rate is quite fast under certain conditions. Corrosion occurs, especially pitting and crevice corrosion.

The corrosion mechanism of stainless steel wire mesh parts is mainly electrochemical corrosion. Therefore, all effective measures should be taken during the processing of stainless steel wire mesh products to avoid rust conditions and incentives. In fact, many rust conditions and incentives (such as scratches, splashes, slags, etc.) have a significant adverse effect on the appearance quality of the product and should and must be overcome.

When stainless steel wire mesh is used as a stainless steel filter mesh, it can block the small diameter size of most solid particles, which is called the filtration degree of stainless steel wire mesh.

The filtration of a stainless steel wire mesh is its mesh size. The actual value of the mesh size directly affects the degree of filtering. There are three types of stainless steel screens: normal filtration degree, filtration degree, and actual filtration degree.

Normal filtration degree (also normal size): refers to the cross section of the woven circular stainless steel dense mesh, the inscribed circle diameter of the triangular hole composed of warp and weft. Filtration degree (also called aperture): refers to the cross section of the twill weave dense mesh, the diameter of the large inscribed circle of the inclined surface of the adjacent two weft wires and the warp wire forming the triangular hole. Actual filtration degree: refers to the degree of filtration of stainless steel wire mesh under actual use conditions.

For a specific specification of stainless steel wire mesh, the actual filtration degree of the stainless steel wire mesh of the same specification changes accordingly when the conditions of use change.

The actual filtration degree of the dutch weave wire mesh is directly affected by the use conditions such as temperature, differential pressure, length of use, viscosity of the medium, and bending times of the filter holes. Therefore, the actual filtration degree is a variable value.

Stainless steel wire mesh is the main material for high-precision product filtration. It can be processed into filters, filter cartridges, filter cartridges, etc. It is widely used in aerospace, petroleum, chemical, pharmaceutical, food, mining, printing, automotive, mobile phones and many other industries.

Stainless steel wire mesh is corroded due to its special metallographic structure and surface passivation film, which is difficult to chemically react with the medium under normal conditions, but it cannot be corroded under any conditions. In the presence of corrosive media and incentives (such as scratches, splashes, slag, etc.), stainless steel wire mesh can also be corroded by slow chemical and electrochemical reactions with corrosive media, and the corrosion rate is quite fast under certain conditions. Corrosion occurs, especially pitting and crevice corrosion.

The corrosion mechanism of stainless steel wire mesh parts is mainly electrochemical corrosion. Therefore, all effective measures should be taken during the processing of stainless steel wire mesh products to avoid rust conditions and incentives. In fact, many rust conditions and incentives (such as scratches, splashes, slags, etc.) have a significant adverse effect on the appearance quality of the product and should and must be overcome.

Post time: Jan-02-2020