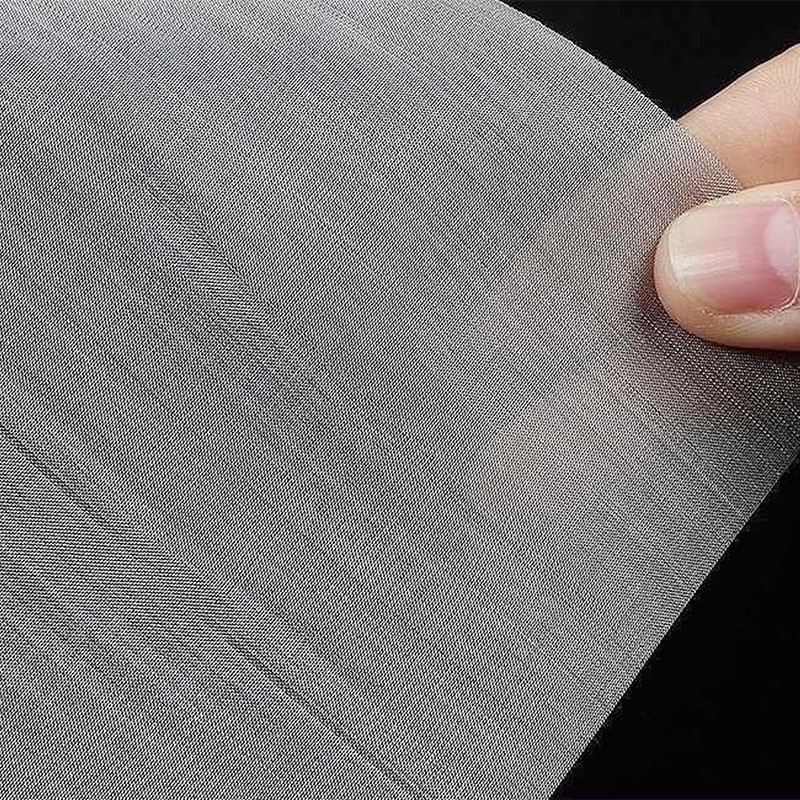

325 Mesh SS304 Filter Mesh Sieve

Material Excellence

Our precision filter mesh is crafted from premium 304 and 316L stainless steel, engineered for durability in harsh environments.

- 304 stainless steel (18% Cr, 8% Ni) offers excellent corrosion resistance in nitric acid (≤65% concentration) and alkali solutions, making it ideal for general industrial filtration.

- 316L stainless steel (16-18% Cr, 10-14% Ni, 2-3% Mo) enhances corrosion resistance by 50% compared to 304, withstanding saltwater, sulfuric acid, and marine/chemical industrial atmospheres.

Both grades meet ASTM B117 5000-hour salt spray test standards, ensuring long-term reliability.

Technical Specifications

| Industry | Typical Uses | Recommended Grade | Mesh Size |

|---|---|---|---|

| Chemical | Acidic powder, reagent filtration | 316L | 325-400 |

| Battery | Electrode slurry, lithium battery powder | 316L | 280-325 |

| Pharmaceutical | API powder, vaccine filtration | 304/316L | 325-400 |

| Food & Beverage | Spice, flour, and juice clarification | 304 | 280-300 |

| Petrochemical | Corrosive gas, crude oil filtration | 316L | 280-300 |

| Ceramics | Glaze powder, ceramic raw material screening | 304 |

300-400 |

Versatile Applications Across Industries

This versatile filter cloth is widely used in numerous sectors, including:

-

Chemical & Pharmaceutical Industry: Ideal for catalyst recovery, filtering aggressive chemical slurries, and separating fine particles in pharmaceutical intermediates. It ensures high purity and withstands corrosive environments.

- Food & Beverage Processing: Used for clarifying syrups, juices, and edible oils. It guarantees product clarity and purity by removing fine sediments and impurities, meeting stringent food-grade standards.

- Energy & Power Generation: Essential for fuel and lubricant filtration in power plants, protecting sensitive equipment from particulate contamination and ensuring efficient operation.

- Mining & Mineral Processing: Excellent for dewatering mineral concentrates, tailings management, and slurry filtration. Its high strength and wear resistance provide long service life in abrasive applications.

- Water & Wastewater Treatment: Employed in fine screening processes, pre-filtration for reverse osmosis membranes, and treating industrial effluent to meet environmental discharge regulations.

- Paint & Coating Industry: Used to filter pigments, resins, and final coatings to achieve a flawless, high-quality finish free of agglomerates and contaminants.

Exceptional Filtration Precision

The precisely controlled 325 mesh configuration (approximately 44 microns) ensures consistent and reliable retention of fine particles, delivering high-purity filtrate and improved product quality.

Durability & Long Service Life

Woven from high-tensile stainless steel wires, this filter cloth exhibits outstanding resistance to abrasion, fatigue, and physical stress. It withstands repeated backwashing and cleaning cycles, significantly outlasting synthetic filter media.

Excellent Corrosion

Manufactured from grades like 304, 316, and 316L stainless steel, it offers robust performance in corrosive environments, resisting acids, alkalis, and oxidation.

30+years production experience

DXR Wire Mesh is a manufacturing & trading combo of wire mesh and wire cloth in the China.With a track record of over 30 years of business and a technical sales staff with over 30 years of combined experience.

Our Products

DXR's main products are stainless steel wire mesh, filter wire mesh, titanium wire mesh,copper wire mesh, plain steel wire mesh and all kinds of mesh further-processingproducts. Total 6 series, about thousand types of products, widely applied forpetrochemical, aeronautics and astronautics, food, pharmacy, environmentalprotection, new energy, automotive and electronic industry.

In 1988,DeXiangRui Wire Cloth Co, Ltd. was foundedannual value of production is about 30 million US dollars.of which 90% of products delivered to more than 50 countries and regions. DXR brand as a famous brand inHebei Province has been registered in 7 countries aroundthe world for trademark protection.

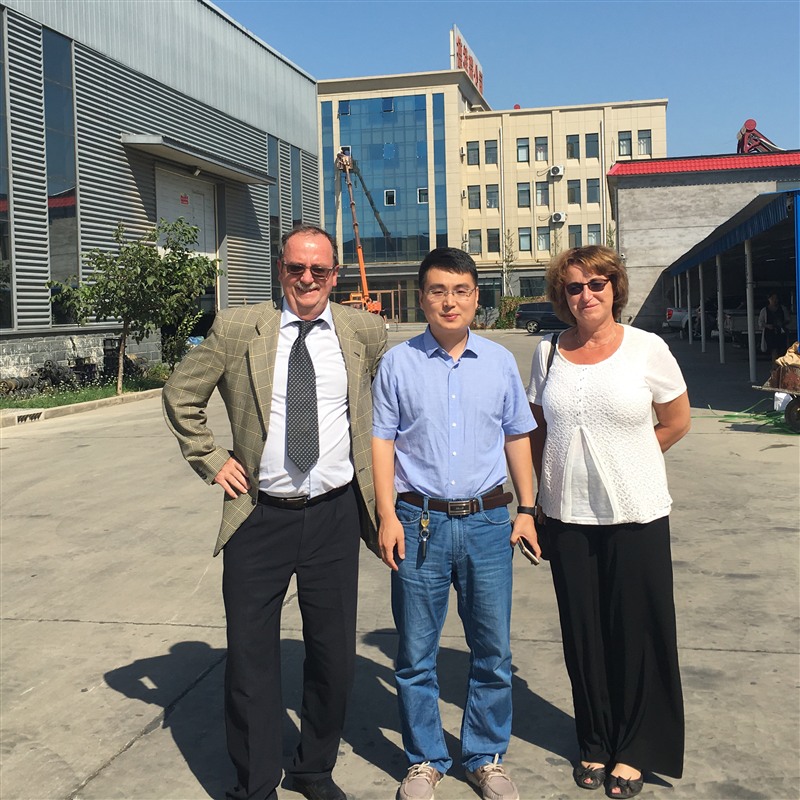

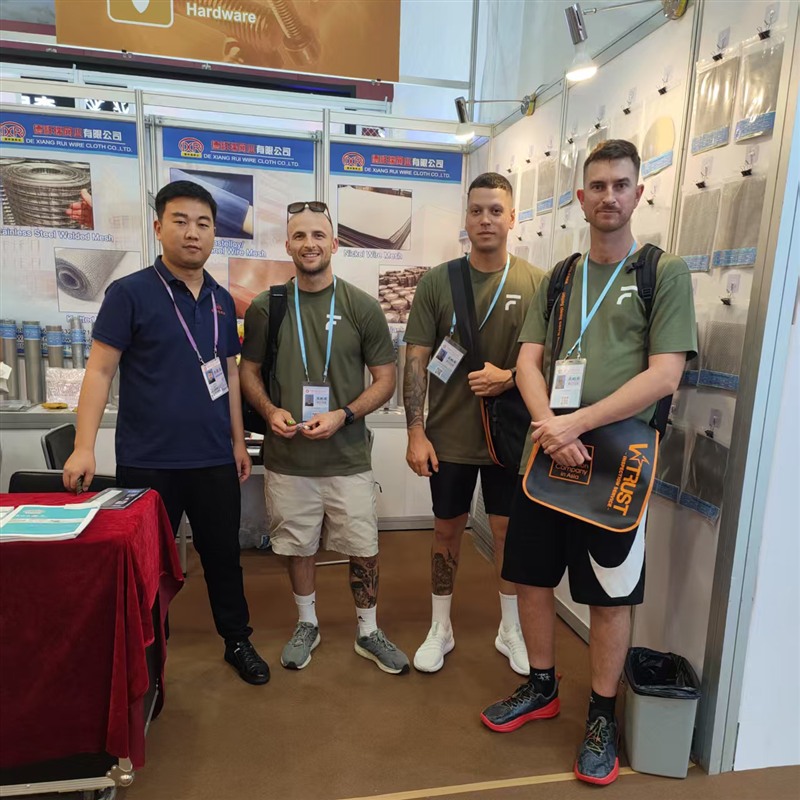

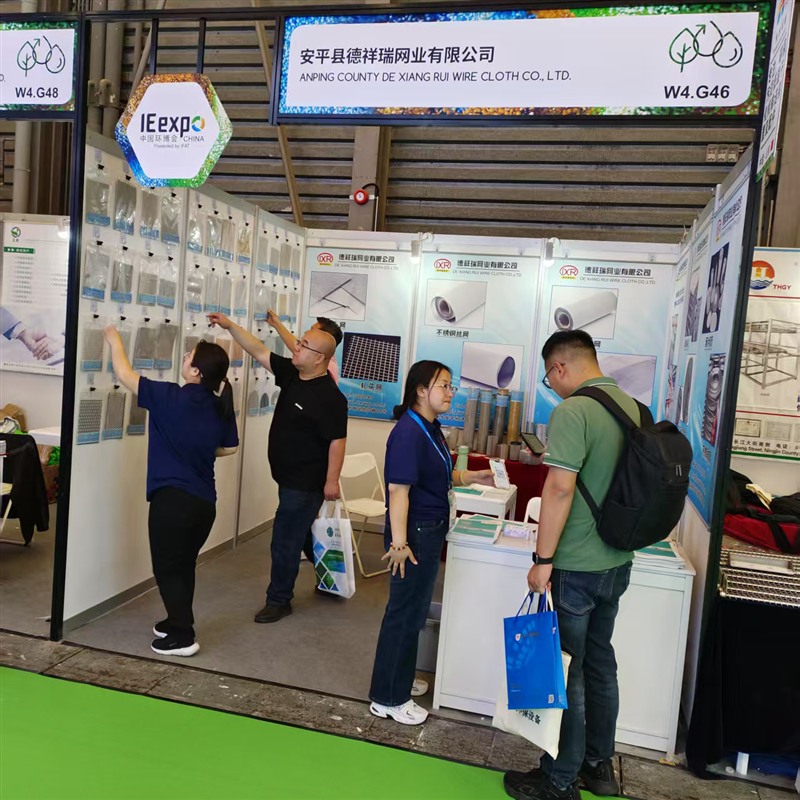

Customers and Exhibitions

Inside The Factory

Workshop