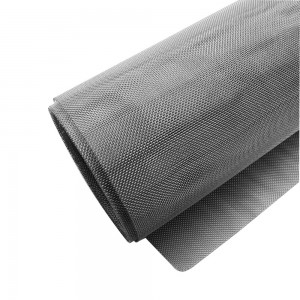

60 mesh Wire mesh corrugated packing

Wire mesh corrugated packing

Wire mesh corrugated packing is a kind of structured packing used in distillation towers and absorption towers. It consists of layers of corrugated wire mesh arranged in a corrugated pattern, creating a large surface area for mass transfer between the gas and liquid phases. This type of packing is designed to provide high separation process efficiency and is typically used in applications requiring high capacity and low pressure drop.

Product Attributes

| Specifications of wire gauze structured packing | |||||

| Model | Specific area(㎡/m³) | Bulk density(kg/m³) | Voidage(%) | Pressure drop(Pa/m³) | Theoretical plate number(m⁻¹) |

| 250X | 250 | 125 | 97 | 100 - 400 | 2.5 - 3 |

| 500X | 500 | 250 | 95 | 400 | 4 - 5 |

| 700Y | 700 | 280 | 87 | 600 - 700 | 8 - 10 |

Advantages

The corrugated design of the wire mesh packing increases the surface area and promotes better mixing of gas and liquid streams, thereby improving mass transfer efficiency. This results in better separation performance and reduced energy consumption during the separation process.

High Strength

Corrugated design provides enhanced strength and stability compared to flat mesh.

Increased surface area

The corrugated structure can better interact with the fluid, improving filtration and separation efficiency.

Corrosion Resistance

The stainless steel option offers excellent corrosion resistance, making it suitable for harsh environments.

Product Application Summary

Wire mesh corrugated packing is usually made of materials such as stainless steel, and is available in a variety of configurations to suit different process requirements. It is commonly used in applications such as distillation, absorption and stripping in the chemical processing, petrochemical, and oil and gas industries.

• Filtration: used in liquid and gas filtration systems to separate particles and pollutants.

• Support Structure: Acts as a support medium in chemical reactors, distillation towers and other industrial equipment.

• Separation: Used in processes where different materials need to be separated based on size or density.

• Soundproofing: Can be used in acoustic applications to reduce noise levels.

30+years production experience

DXR Wire Mesh is a manufacturing & trading combo of wire mesh and wire cloth in the China.With a track record of over 30 years of business and a technical sales staff with over 30 years of combined experience.

Our Products

DXR's main products are stainless steel wire mesh, filter wire mesh, titanium wire mesh,copper wire mesh, plain steel wire mesh and all kinds of mesh further-processingproducts. Total 6 series, about thousand types of products, widely applied forpetrochemical, aeronautics and astronautics, food, pharmacy, environmentalprotection, new energy, automotive and electronic industry.

In 1988,DeXiangRui Wire Cloth Co, Ltd. was foundedannual value of production is about 30 million US dollars.of which 90% of products delivered to more than 50 countries and regions. DXR brand as a famous brand inHebei Province has been registered in 7 countries aroundthe world for trademark protection.

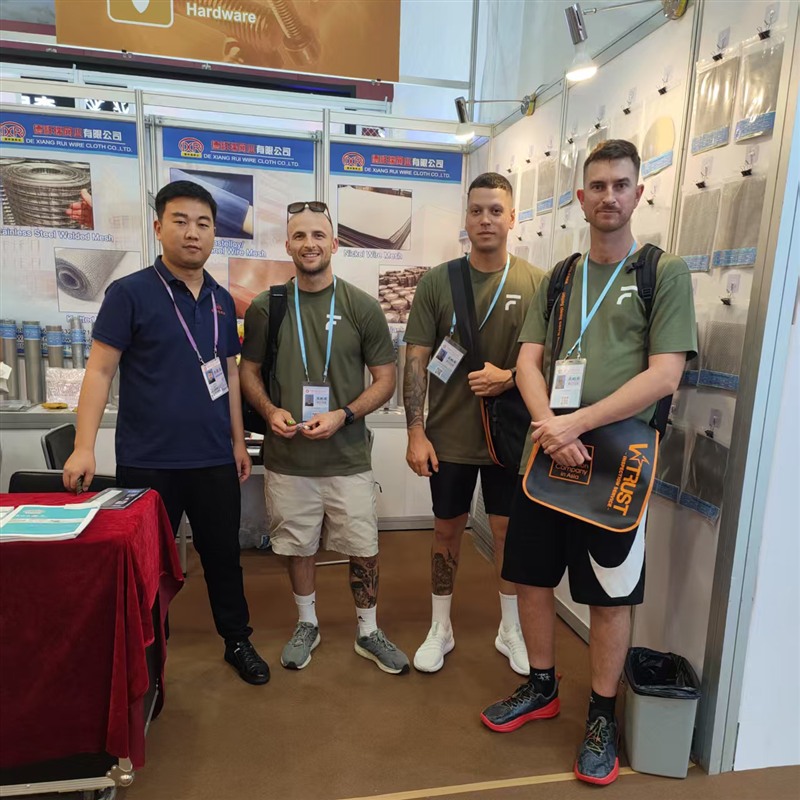

Customers and Exhibitions

Inside The Factory

Workshop

Production Machine

FAQ

Q1: Is it all right to make customer's own brand name?

A: Yes, we offer OEM service.

Q2: Are you a manufactuer or trading company?

A: We are a professional manufacturer since 1988.

Q3: Can you do the design for us?

A: Yes,Both design and customization are available

Q4: How can I get a sample to check your quality?

A: Please send us an email to sales88@china-wiremesh.net or contact us through this website. We will arrange samples via DHL, FedEx, UPS etc.

Q5: Is the sample free,and How long can I expect to get the sample?

A: Although we support free sample, you need pay the freight.It depends on your address how long it will take to receive it. We can do all the sample in 2 days

Q6: Packaging & Shipping:

A: "Water-proof paper,plastic film, wooden cases or pallets outside.

By sea, train, sea and air. "

Q7: What about the lead time for mass production?

A: Common specifications within 30 days

Q8: Where is your loading port?

A: Tianjin, Qingdao

Q9: How long is the delivery period of the product?

A: 2-30 days

Q10: What quality certifications do you have?

A: CE, ISO 9001:2015, SGS